Loading the 8.15x46R

A German Classic in a Teutonic .32-40

feature By: Terry Wieland | April, 20

The world of German Schützen rifles is a continuing mystery to American shooters, and if the rifles themselves are baffling, contriving ammunition is doubly so. It sometimes seems as if German target shooters did everything differently than we do.

There are so many German single-shot actions and such a variety of cartridges, you could spend a lifetime studying them and still find surprises. Most of the rifles were made by independent craftsmen, and each had his own idea of what constituted a good cartridge. Every rifle is an individual, every second cartridge is a pseudo-wildcat, and just to put the icing on the cake, very few of the rifles have any kind of caliber marking on them. Very often, the first step in developing ammunition is making a chamber cast, measuring the result and then trying to puzzle it out with old catalog entries.

Looking at the list of cartridges developed in central Europe for Schützen competition between 1860 and 1900 makes the American counterparts from Sharps, Peabody, Winchester and so on seem paltry. As for standardization, there was none, or almost none.

In 1909, realizing this was a serious problem for the more popular cartridges, German rifle and ammunition makers convened a meeting of interested parties to try to bring some order out of the chaos. The committee standardized four cartridges (henceforth distinguished by the word “Normal” or “Norm” appended to the headstamp), one of which was the – by 1910 – dominant cartridge for Schützen competition, the 8.15x46R.

In one way, the German progression of popular cartridges closely resembled what occurred in America. After the development of the centerfire, drawn-brass case, the first target cartridges were big and heavy. We had .45s and .44s; Germany had 11mms and 12mms. America progressed from .44 down to .40 then .38 and eventually settled on the .32-40 about the time smokeless powder began seriously displacing black powder.

German cartridges shrank to 10.5mm then 9.5mm until, in 1893, Adolf Frohn introduced a small cartridge dubbed the 8.15x46R – more or less. It went by several different designations between 1893 and 1910, when it was standardized. There are references to the 8.15x46½R and 8.15x46.5R. The former is the one and only time I have seen Germans use both a fraction and a decimal in one cartridge designation. There was almost certainly a reason for it, but I just can’t imagine what it was.

When the standardization committee met in 1909, the 8.15x46R was the only Schützen cartridge “Normalized,” probably because it had become so dominant by that time it was expected that in the future it would be the only one in widespread production. The Great War (1914-18) intervened, and when civilian cartridge production was resumed afterward it was one of the few cartridges to return. In fact, it survives to this day, with RWS producing both cases and loaded ammunition.

Being slightly smaller and less powerful than the .32-40, which is marginal for any kind of big-game hunting, the 8.15x46R was used mostly for target work, although it was also employed as a small-game chambering for drillings and the like. As a result, most bullets and loads are intended for target shooting, which brings us to the nuts and bolts of loading ammunition.

To understand why German loading components and techniques developed the way they did, we have to understand the culture in which the Schützenfest flourished. Everything was interrelated. This included rifles, cartridges, the way they were chambered, the bullets designed for use in those chambers and the way in which powder was portioned out – everything.

To start with, German shooters travelled many miles to get to matches, usually by train or other public transport. Weight and bulk were important considerations, which led to the popularity of takedown rifles and smaller calibers. Components weighed less than loaded ammunition, so loading for yourself, as needed, was preferable. The less equipment you carried, the better, so manufacturers devised ways of pre-measuring powder. This eliminated the need for a scale or powder measure. Loading dies were done away with by using cases that were unsized and seating bullets using finger pressure. This in turn dictated bullet design. Now, let’s look at each of these individually as they affected the 8.15x46R.

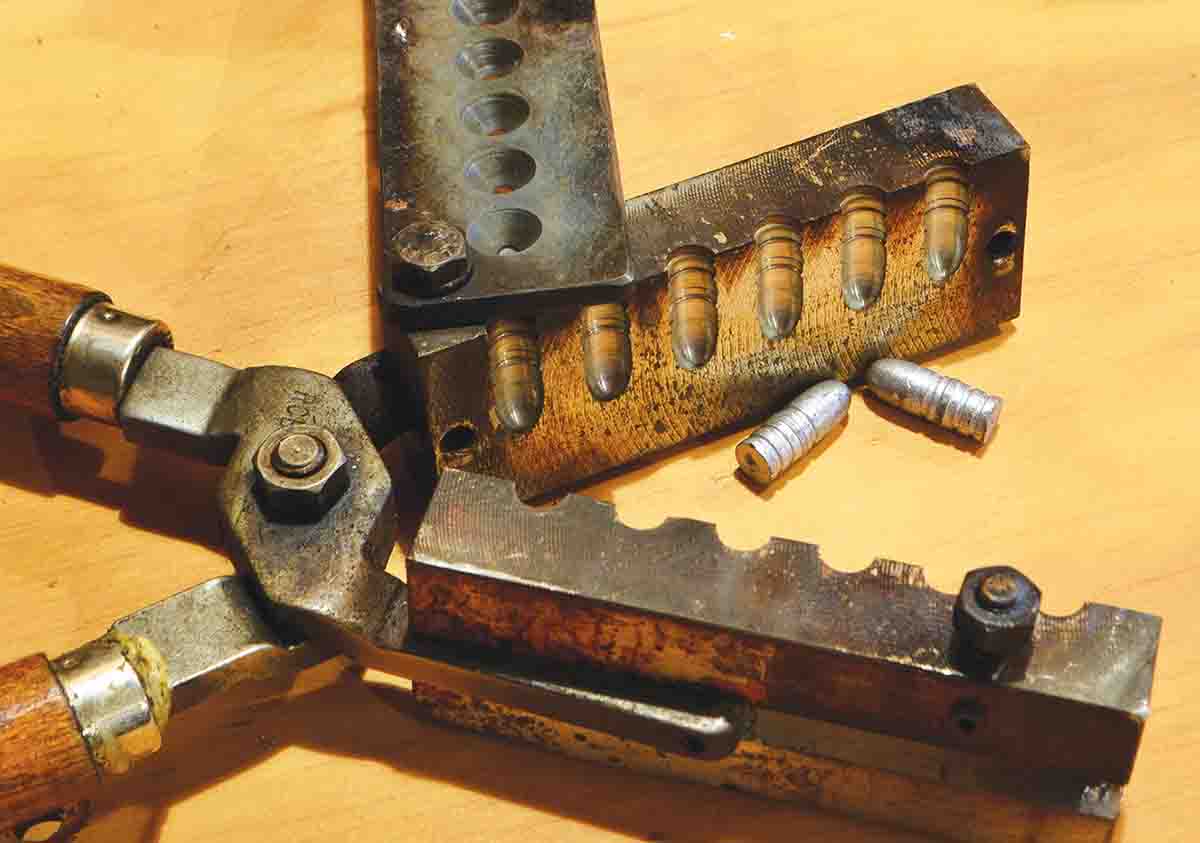

To start with the chamber, a chamber cast looks unusual because it has no sharp edge at the mouth of the case. Instead, it tapers gradually to the rifling. A sharp edge was not possible because the most popular bullet for the 8.15 was a 180-grain roundnose with several lube grooves and one central “seating band” that was a greater diameter. The shooter would lube his bullet by hand, then press it into the case mouth. The seating band came in contact with the case mouth, preventing it going any deeper. Automatically, all cartridges were uniform in length. Since the chamber had to accommodate the wider band on the bullet; however, there was no sharp edge.

Of the many bullet designs, the most popular was one designated the “16H” and the bullet shown in an accompanying photo replicates that design. Collectors report that German bullet moulds were rather crude by American standards. The reason is, German bullet makers learned to fashion the 16H using swages, and commercial swaged bullets became the standard. This eliminated the need for bullet lubricating sizers as well.

The bullet I used came from a custom mould. In the 1970s, Bob Hayley (Hayley’s Custom Ammunition) had a mould made to duplicate the bullet from a post-war commercial RWS round. This allows him to provide bullets to keep the old German rifles shooting. Although the original design had a “hollow” base, Hayley’s bullets do not. The term “hollow” is deceptive, because it was actually concave, not a large cavity like a Minié ball.

From the mould, Hayley’s bullet measures .321 to .322 inch on the shank and .338 inch on the driving band. The Redding expander ball is .322 inch. Normally, the sizing die would leave the neck slightly smaller than bullet diameter to provide a firm grip. With finger-seating, you need the neck almost exactly the same diameter as the bullet – not too tight, but not too loose, either. With the above tools and components, some bullets seated readily while others did not.

European cases were universally Berdan-primed, and one simple tool handled both capping and de-capping. Powder was another matter, especially the early smokeless varieties where you did not simply fill the case to the base of the bullet. German powder makers formed powders into compressed blocks that were sold in boxes of 100. All you did was pull one out, drop it in the case and seat the bullet. They soon found, however, that it was easier and more flexible to put loose powder in little packets made of nitrated paper, which were dropped whole into the case. These packets were about the size and shape of a cigarette filter. The paper was consumed by the combustion of the powder.

Again, all weighing and measuring implements were eliminated. A shooter could travel to a match carrying only the capper/de-capper and a few cases, along with a supply of primers, powder packets, swaged bullets and a tin of lubricant.

This train of cause and effect led German shooters in a completely different direction from Americans, who immediately began experimenting with different powders, powder charges, bullet weights and combinations of black, semi-smokeless and smokeless powders. This evolved into our culture of wildcatting and handloading for ultra-accuracy that lives to this day.

The immediate question that springs to mind is, why were German shooters not more conscious of accuracy and the factors that contributed to it if their matches were so important and there was so much prize money at stake? There is no easy answer, and since none of the competitors are around today to offer one, we can only surmise. The American authors of the massive three-volume tome Alte Scheibenwaffen, who are all collectors and spent years researching in Germany, came to the conclusion that pinpoint accuracy, as we define it, was simply not necessary.

Offhand shooting was the dominant discipline, commanding the most interest on the part of both competitors and spectators. It involved the biggest money and the most prestige for the winners, who became national heroes. As anyone who has tried it will attest, there is a lot more to shooting offhand than having the most accurate rifle and ammunition, even at 300 meters. German gunmakers devoted far more effort to developing the very finest set triggers, the best sighting apparatus and the most ergonomic stock designs than they did to minor (!) matters like powder charges and bullet weights.

Loading for the 8.15x46R today is simpler in some ways, but it also presents difficulties. RWS brass is Boxer-primed and powder is measured in our usual way. With new brass, you simply condition the neck – making it perfectly round, beveling the mouth and so on – then use a mild load with any .32-caliber bullet. Very likely, it will be a tight fit and you will need to use a seating die. However, firing it expands the case to chamber dimensions and opens the neck up enough that from that point on you can load it with 16H bullets with only finger pressure. It’s sometimes possible to bell the neck ever so slightly to make seating the bullet easier, but too much belling will make it difficult to chamber.

If pressure is kept down, the case will not even need neck resizing after firing. It is a simple matter to de-prime using a punch, rather than a sizing die. As long as the case slips into the chamber easily, no sizing is needed. It’s difficult to give precise instructions for all these procedures because there are so many variables. One just has to know the ultimate aim and use handloading experience to get there.

Of course, if a handloader does not demand absolute authenticity in procedure as well as components, a conventional seating die works perfectly well. With the 16H bullet, just be careful not to try to force it down too far.

Because of the seating band, 16H bullets cannot be lubed the usual way. With finger-seating, smear some soft lube into the grooves, front and back, push it into the case then wipe off the excess. This has to be done the same way if using a seating die.

In developing loads, the goal is not the highest velocity, but optimum accuracy combined with pressures that will not stress the case and force you to do much resizing. The accompanying table gives starting points with the two most appropriate powders, H-4198 and IMR-3031. IMR-4198 would work just as well. Published data for factory 8.15x46R is hard to come by, so there is no real basis of comparison. Cartridges of the World, 10th edition (2003), suggests that RWS factory ammunition with 151-grain jacketed softpoints delivers 1,900 fps, which is not terribly helpful. My experience is that pushing a 184-grain 16H bullet at 1,200 to 1,400 fps is about right. Somewhere in that range lies the best accuracy combined with the desired pressure.

Since its first edition in 1965, Cartridges of the World has recommended a load of 23 grains of “3031” with a 190-grain cast bullet at a purported velocity of 1,500 fps. I backed that off to 20 grains, having a hunch that 23 grains was too hot – not that it might damage the action, but simply expand the case too much for finger-seating. I was right about that, and if I were using that powder, I would not go heavier than 20 grains. Of course, a lot depends on individual rifle chambers.

Having gone through the lengthy 12-month process of completing the restoration, action and trigger repairs and adjustments, having sights made, finding bullets and cases and developing loads, however, I want to assure readers that it was well worth it. This old Schützen rifle is a sweetheart.

.jpg)