Propellant Profiles

Winchester StaBALL Match

column By: Randy Bimson | June, 23

Now, there is no denying we handloaders are starting to get some respite in propellant powder availability, but there is still a ravenous market for propellants and a lot of empty space on our favorite component dealer’s shelves. Another fellow was braving the weather and testing some loads he had worked up for his newly acquired rifle chambered for the 6.5 PRC cartridge. Spotting my portable reloading setup, he came over to my bench and struck up a conversation that went something like this: “What the hell are these companies thinking? I hear Winchester just announced two new rifle ball powders. They can’t supply the powders they currently offer and now they are adding even more new powders?” This was one of those conversations that if one gets involved in, it burns up a lot of daylight, and daylight was a commodity that was getting in as short in supply as propellant powders were at that point in time, so I deflected the question, pleaded ignorance (he did not know that I write this column), and we both went back to the more pleasurable and pressing pastimes of handloading and shooting.

I must admit that it can be perplexing if you have not been “in the trenches” and know something about the goings-on of the propellant industry. The long and the short of it is that research and development continues to sometimes find a better, faster, way to make product and sometimes to “make a better mousetrap.” Winchester StaBALL HD and StaBALL Match, the subject of this issue’s column, is the result of the latter.

In the 1930s, DuPont de Nemours, Inc., coined the phrase “Better Living Through Chemistry.” Yup, the same DuPont that brought us “nylon” and IMR and other propellant powders. Well, it just so happens that strides in chemistry have made our lives as shooters a whole lot easier in recent years with the advent of propellant additives, which help to eradicate copper fouling and substantially reduce temperature sensitivity of the propellants we use. Hodgdon’s Extreme extruded propellants brought us the first temperature-stable propellants, followed by the Enduron series of extruded propellants, which incorporated the first copper fouling reducing ingredient.

Winchester StaBALL 6.5 was the first spherical powder to market that offered all three of the above mentioned performance-enhancing elements. The addition of the recently introduced StaBALL HD, and the focus of this column StaBALL Match, give the handloader all-inclusive performance enhancing elements in three spherical propellants that will accommodate the gauntlet of cartridges, short, fat, long or skinny, from likes of the diminutive 204 Ruger to the 375 H&H Magnum.

StaBALL Match is my first choice of the two latest StaBALL powders to review principally because it covers so many of the cartridges that I have a great affinity for and shoot often. Cartridges such as the 222 and 223 Remington, 220 Swift, 22-250 Remington, and 6mm Remington. All cartridges that have or do support my prairie dog and gopher hunting habit.

From the technical perspective StaBALL Match, as previously noted, is a spherical propellant, produced at the St. Marks propellant works in Florida. This is a good time to make mention that St. Marks, along with General Dynamics Ordnance and Tactical Systems-Canada Valleyfield Inc., located in Valleyfield, Quebec, Canada, and Alliant/New River Energetics, located in Radford, Virginia, are the three principal small arms propellant works in North America. In fact, a great portion of the propellant powders for the handloading market are imports from Europe and Australia. The StaBALL line of powders is one step in lessening the industry’s dependency on imported propellant powders and the subsequent long order times and shipping delays.

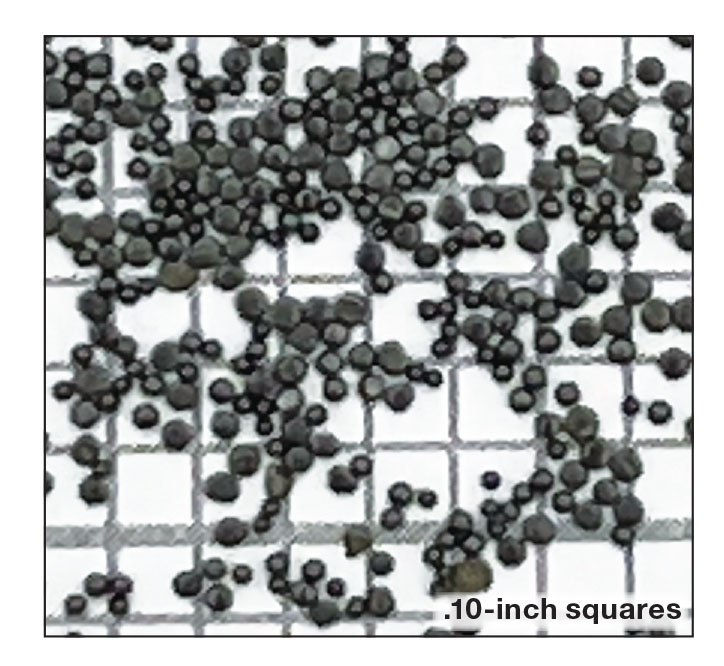

Physically, StaBALL Match at a glance, would be hard to distinguish from many other Winchester Ball Powders. Comprised of spherically-shaped granules that are a distinctive metallic gray-black color, the granules range in diameter from .0139 to .0331 inch. The nitroglycerin content of StaBALL Match is a nominal 10.50 percent and the bulk density of StaBALL Match is 0.96 g/cc. A more graphic example of the density of StaBALL Match, for example, is the 220 Swift case where the Hodgdon 2023 Annual Manual shows a maximum load of 37.4 grains of StaBALL Match combined with my favorite Sierra 52-grain hollowpoint boat-tail bullet, Winchester WLR primer, in a Winchester case; the same Winchester 220 Swift case capacity is a maximum of 43.4 grains to StaBALL Match to the base of the neck case. This type of load density is ideal for creating the perfect attribute for small standard deviations in pressure and velocity. In the most current Hodgdon Relative Burn Rate Chart, StaBALL Match sits in the number 106 spot, right between Winchester 748 (No. 105) and Hodgdon BL-C(2) (No. 107).

In addition to some of my favorite cartridges mentioned above, Hodgdon also has considerable data for StaBALL Match in other popular cartridges like the 6mm Creedmoor, 6.5 Creedmoor, 260 Remington, 7mm-08 Remington, 308 Winchester, and 30-06 Springfield where it typically shows very good economies of powder charge to velocities generated. They also have data for more specialized loads like 308 Winchester Service Rifle Loads (M14/M1A pattern rifles), 338 Federal, 444 Marlin, and to my surprise 45-70 Government “trapdoor” and “lever-action” class loading data.

Temperature stable, copper fouling-reducing and copper fouling-removing additives, optimum loading density in appropriate cartridges, and best in class velocities in many, Winchester StaBALL Match is a made-in-the U.S. powder that does a lot of the things that contribute to match-grade accuracy so very well. When you see it on your dealer’s shelves, buy a canister. I think you will find it a good “fit” in your powder inventory. Available in 1- and 8-pound canisters.

.jpg)