Propellant Profiles

Shooters World Ultimate Pistol

column By: Rob Behr | April, 25

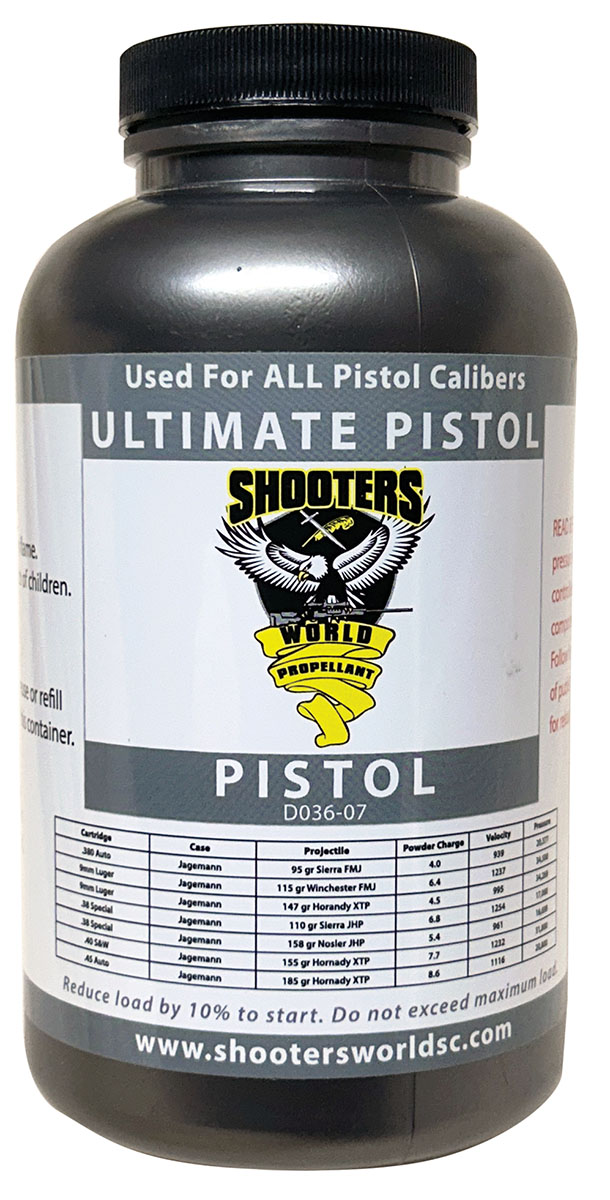

If there is a sweet-spot powder for handloaders who are looking for efficient loads, Alliant Unique is a good example. Ask a Cowboy Action shooter what they are loading in their 38 Special single actions, and more than a few will say they choose Unique. They may also add that it has been hard to find lately. Shooters World is aiming to fix that with a Czech-made propellant they are calling Ultimate Pistol. Designated D036-07 by Lovex, this powder offers a burn rate slower than Accurate No. 2 and on par with Winchester AutoComp and Alliant Unique. After testing, I can say that it has ignition characteristics that may put it at the top of the heap for high-volume handloaders looking for efficiency and reliability.

Physical Characteristics

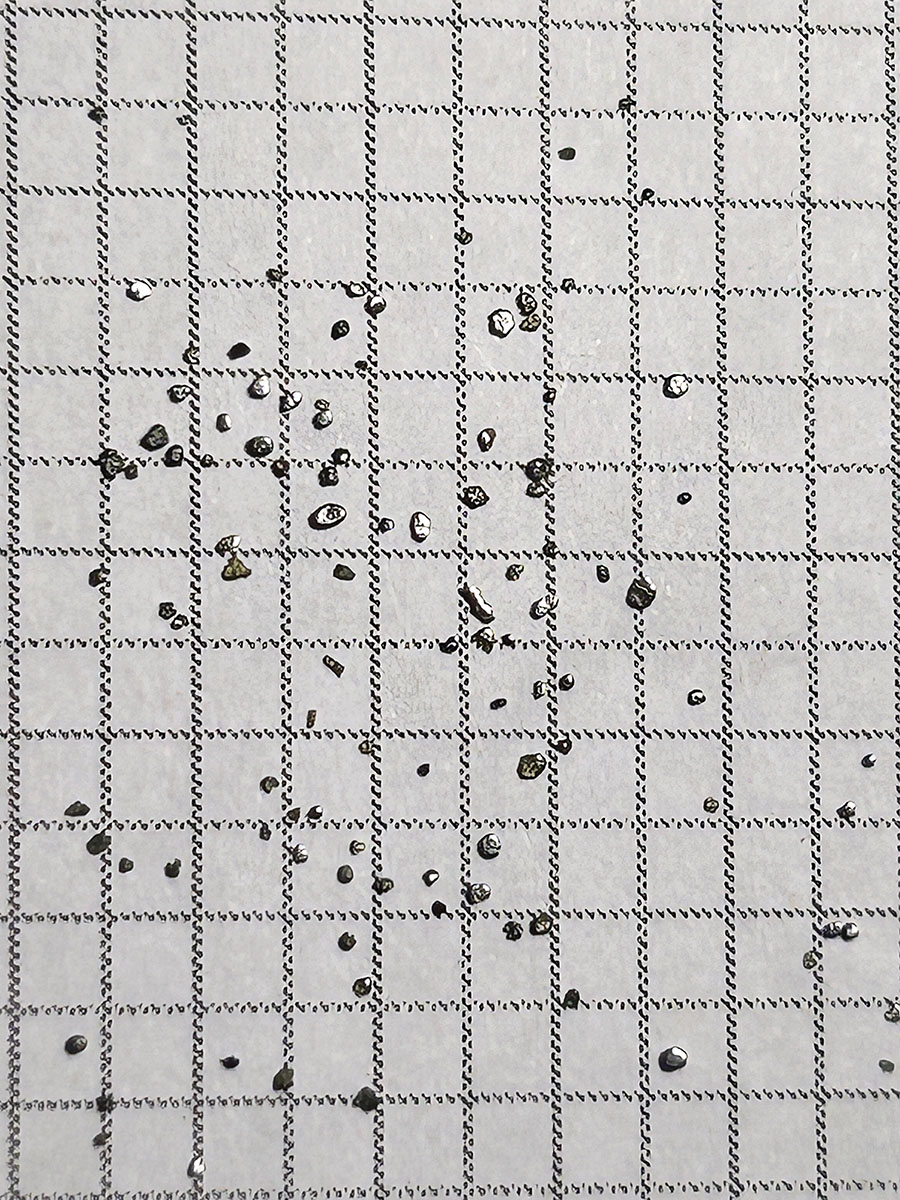

When I poured some of this powder onto a piece of graph paper, I was surprised by the sizes and shapes of the individual powder grains. Through the magnifying lens of my camera, I saw a kaleidoscopic view of flattened spheres, tubes and non-reflective grains that looked like jagged pebbles. Most were extremely fine. There were so many different shapes that getting an accurate measurement of each type would have been an impossible task. I compromised by measuring one of the flattened spheres. That grain measured 0.029-inch in diameter by 0.009-inch in thickness. I have come to expect inconsistent grain shapes in Lovex powders, but I have never seen one like this.

Ultimate Pistol is a double-base powder with a bulk density of 0.92 grams/cc, which is modestly higher than Unique. Considering that Unique is a double-base flake powder, I wondered if Ultimate Pistol would ignite as well as its competitor when exposed to lower-pressure ignitions with the powder oriented less favorably in the cartridge. I added that testing to my list.

Temperature Stability Testing

In a ballistics lab, propellants are conditioned in an environment held constant for temperature and humidity before testing. I keep my office at about 70 degrees Fahrenheit, which is consistent with the accepted lab standards. Testing outdoors makes for a trickier environment. On my first day of test shooting, the outdoor range temperature was a balmy 27 degrees. To keep the cartridges closer to the desired test temperature, I stored them in a cooler that had been stored in my office overnight and limited the amount of time I opened the lid. Storing the ammunition in my warm Jeep made for more walking back and forth to the vehicle, but it also limited how frequently the test ammunition was exposed to colder air.

I also wanted to test Ultimate Pistol’s stability at extreme temperatures. Lab standards vary, but testing usually runs somewhere between -20 degrees and 120 degrees. I picked the 9mm Luger for this job because of its ability to withstand high pressure. The chosen loads were already listed as maximums from data supplied by Shooters World, and the ammunition was going to be exposed to temperature extremes. Higher pressures were to be expected.

The methodology for cold testing was simple. I moved some elk around in one of my chest freezers and made room for an insulated container and a bunch of carefully loaded 9mm cartridges. Leaving them there overnight produced a batch of very cold 9mm cartridges stabilized at -22 degrees.

Finding a hot testing method proved more elusive. Labs use specialized ovens to condition powder, but like most scientific equipment, they are expensive. The answer came to me while I was cooking a steak with my sous vide. These kitchen gadgets are used to heat food to a specific temperature in a water bath and maintain that temperature over many hours. Restaurants use them to maintain steaks at a level of doneness to speed up the cooking process. It is a valuable tool for chefs and now for amateur ballisticians. I sealed the ammunition in a vacuum pouch and set the little machine to 120 degrees. Twelve hours later, I had piping hot cartridges in an insulated container, and I was ready for testing.

The test pistol was a Turkish-made Derya Melik, a credible clone of a Beretta 92. With a 4.9-inch barrel and very reasonable price, it seemed the perfect test pistol to risk with cartridges that were at the extremes of both pressure and temperature.

The first shot from the frozen cartridges registered 1,386 feet per second (fps), almost 150 fps faster than the load data from Shooters World anticipated. It was clearly over- pressure, and the primer showed modest cratering with edges that were still rounded. When the testing was finished, the average velocity had dropped to 1,366 fps with an extreme spread of 61.6 fps. The hot cartridges produced an average velocity of 1,348 fps. The cartridges evaluated at 70 degrees landed smack in the middle with an average velocity of 1,354 fps. The shift between the hot and cold extremes was only 18 fps, representing a velocity shift of only 1.3 percent.

There are several points worth noting from this testing, even with such a small sample size. The cold cartridges developed slightly higher pressure. This is a hallmark of nitroglycerin, which often produces higher pressures when cold. The hot cartridges exhibited the smallest extreme spreads of all the cartridges, coming in at 18.9 fps with a standard deviation of 6.9. This standard deviation was the lowest of all the cartridges evaluated, not just in the 9mm Luger.

Positional Stability

The 45 Colt was designed for black powder, a heritage that shows in its voluminous case capacity of 41.5 grains of water. Loaded at SAAMI pressure standards, the cartridge is held to an extremely low operating pressure of 14,000 pounds per square inch (psi). This combination often requires low charge masses, making the cartridge a good test bed for ignition issues associated with the powder’s position within the cartridge.

Loaded with 8.5 grains of Ultimate Pistol and a hard-cast 250-grain bullet, there was plenty of room for the powder to migrate. To enhance the effect of the powder positional sensitivity, I fired half of the test cartridges with the powder oriented to the rear of the case. To do this, I aimed up and slowly brought the pistol down to the point of aim. The other half were fired in the opposite manner, with the powder oriented toward the bullet. The result was that there was no significant velocity difference based on orientation. At least with this bullet and charge combination, this Shooters World powder proved to have exceptional ignition characteristics.

.jpg)