Wildcat Cartridges

.17 Mach IV

column By: Layne Simpson | August, 18

One of those hunters was Vern O’Brien, owner of a shop in Las Vegas called O’Brien Rifle Company. The “bear slayer” was built by him on the dainty Sako L461 action, and its .17 Mach IV cartridge pushed a 25-grain bullet along at 3,700 fps. As the story went, O’Brien had wagered his rifle that the guide could not kill the bear with it and lost the bet. Would close examination have revealed a .375-inch hole or two in the bear’s hide? We will never know. Whether the tale was fact or fiction will long be debated, but it likely sold quite a few .17-caliber rifles, not to bear hunters, but to varmint shooters like me.

In 1970 I bought the field version of the O’Brien rifle in .17 Mach IV from a friend who decided the .222 Remington was more fun. The rifle, along with a cleaning rod and RCBS case forming and reloading dies, came in a metal case. Some years later an avid collector of O’Brien rifles made an offer I simply could not refuse. He had no interest in the dies or my boxes of handloads, so to this day they reside in my reloading room.

When domesticating wildcat cartridges, Remington has for the most part stuck with the original case shape and dimensions as closely as possible. In other words, the new is pretty much the same as the old. Examples that spring to mind are the .25-06 Remington, 7mm Remington Magnum, 7mm Shooting Times Westerner and the .35 Whelen. Examples that differ from the originals include the .257 Roberts, and to a lesser degree, the .17 Fireball. Some shooters consider the .17 Mach IV and .17 Fireball to be one and the same with the name changed because “.17 Mach IV” was a Vern O’Brien trademark. That is not quite true.

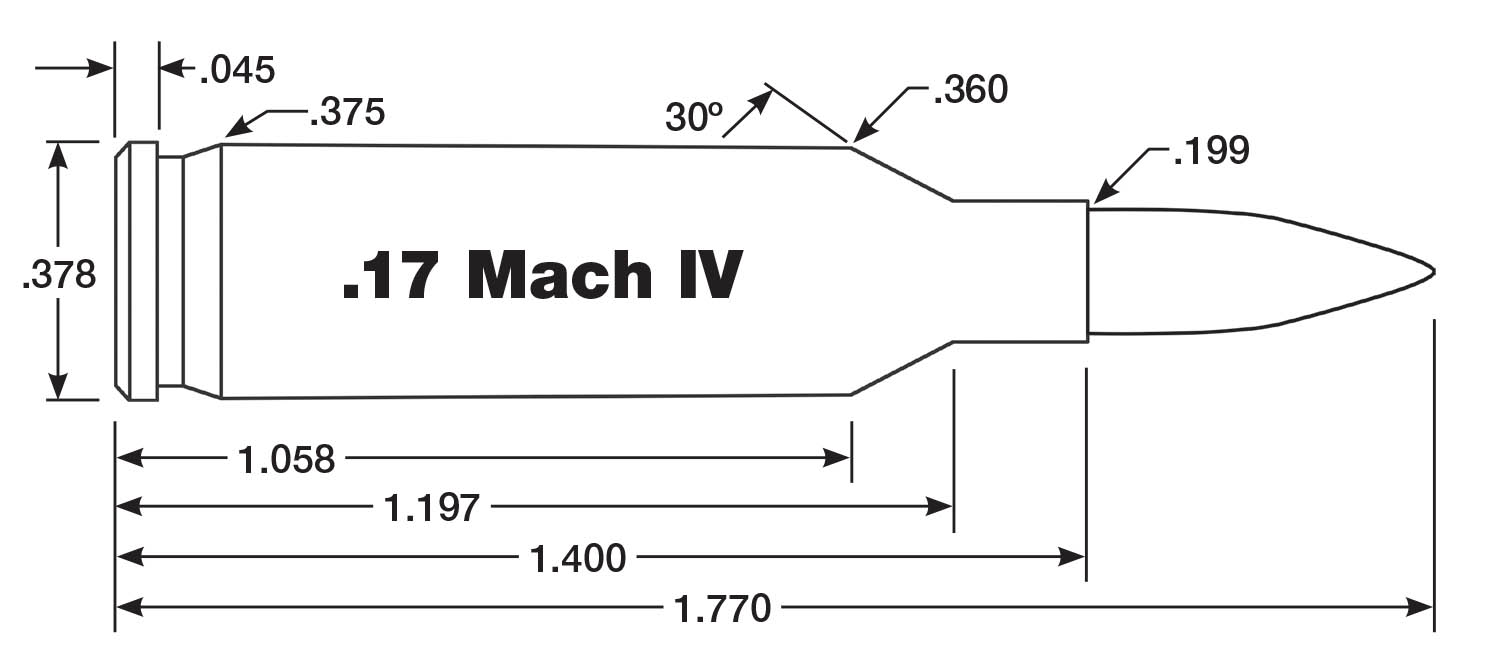

Dimensional differences between the two cartridges are minor, and they vary a bit among reloading manuals. Cartridge drawings in Hornady’s Handbook of Cartridge Reloading, 9th Edition show maximums of 1.058 inches from the head to body/shoulder junction and 1.197 inches from head to the shoulder/neck junction for the Mach IV versus 1.065 inches and 1.205 inches for the Fireball. Maximum diameters at the junction of the body and shoulder are .360 inch for the Mach IV and .366 inch for the Fireball. Some .17 Mach IV dimensions in the new Western Powders Handloading Guide, Edition 1 differ from those in the Hornady manual, but they are

As rumor has it, Remington moved the shoulder of the .17 Fireball case a bit forward to prevent it from being chambered in rifles chambered for the Mach IV. Whether or not that is true I cannot say, but it is not uncommon for the Fireball cartridge to seat all the way home in a Mach IV chamber. It is usually a crush fit, so pushing the bolt all the way into battery can require a bit of muscle. I have attempted to chamber .17 Fireball factory ammunition in two Mach IV rifles, a Cooper Model 21 and a rebarreled Remington Model 700 purchased off the rack at a local gun shop. One accepted it, but only with plenty of muscle behind bolt closure. The fit was so tight that continued use of factory ammunition would likely have eventually resulted in locking lug galling.

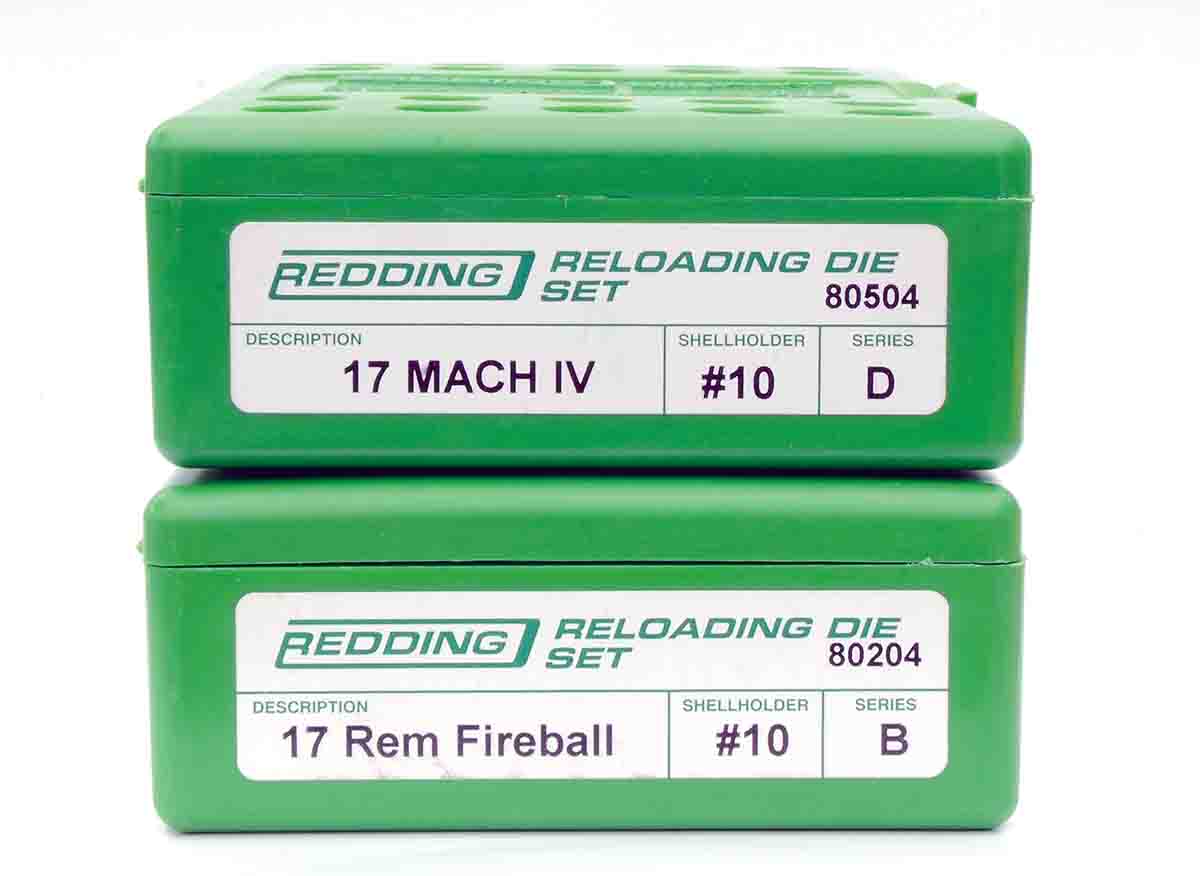

Redding offers two distinct and specific die sets for the two cartridges. According to Robin Sharpless of that company, headspace dimension for the .17 Fireball is .003 to .004 inch longer than for the .17 Mach IV. The .17 Fireball is also .003 to .004 inch longer when measured from head to junction of the body and shoulder as well as from head to shoulder-neck junction.

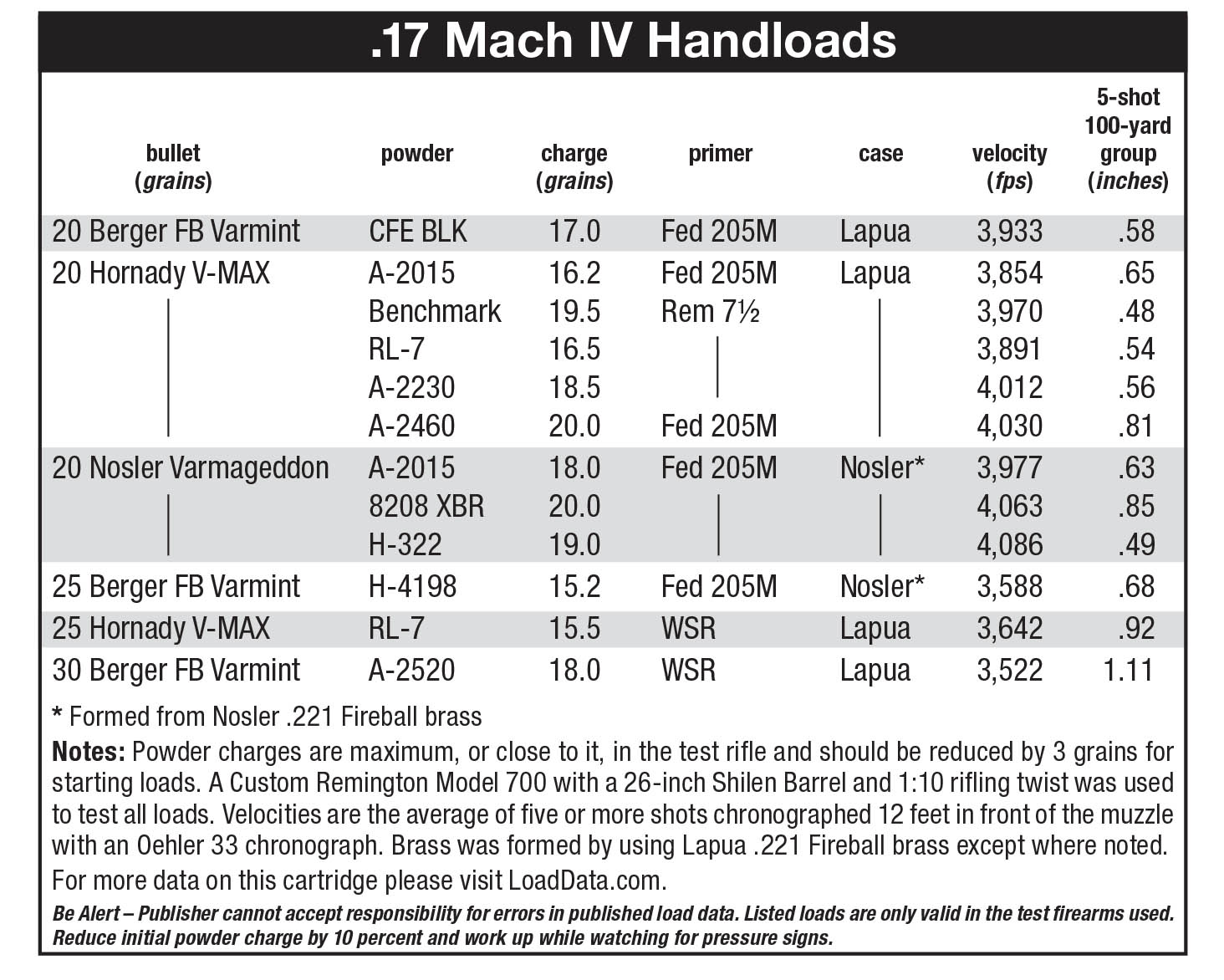

While some dimensions do vary, they are not enough to greatly affect powder capacity, and for that reason load data is quite similar. Data in the Berger manual is exactly the same for the two cartridges. Starting and maximum charge weights between the two differ slightly in the Hornady manual, but no more than to be expected from different lots of powder or slight differences in barrels, cases and bullets; same goes for data in the Western Powders manual.

RCBS form and loading dies that came with my O’Brien rifle are still being used for the Model 700, but a Redding neck-sizing die with interchangeable bushings has been added. A bushing .001 inch smaller than the diameter of the neck of a loaded round is perfect for new brass, but after the brass loses some of its elasticity from several firings a switch to .002 inch is made. After forming many .17 Mach IV cases for high-volume varmint shooting, I have come to the conclusion that Lapua .221 Fireball cases cannot be beat. They cost more but in addition to being exceptionally uniform in weight, their hardness enables them to withstand more maximum-pressure firings than other cases. Nosler cases do not last as long, but they are of better quality than .221 cases made by Remington. Regardless of the brass used to form .17 Mach IV cases, neck diameter of a loaded round should be at least .005 inch smaller than the chamber neck diameter of the rifle in which they are fired.