Brian selected a Linebaugh Custom Sixguns Ruger New Model Blackhawk Bisley (top) and a Freedom Arms Model 757 (bottom) to develop 475 Linebaugh handloading data.

In 1983, I was contacted by a mostly unknown sixgun smith named John Linebaugh who lived about 40 miles north of Cody, Wyoming. At the time, he was pouring cement to support his wife and two young boys, but on the side, he was building experimental and custom sixguns and trying to break into the gun business on a full-time basis. He sent me an early example of his work that was built on a Seville frame, fitted with an oversized six-shot cylinder that was chambered in 45 Colt with properly-cut chambers and a match-grade barrel. He forwarded load data that was impressive and easily outperformed the 44 Magnum. His sixgun proved very well made, offered solid cylinder lockup and was especially accurate.

The 475 Linebaugh test guns included (top to bottom): a Freedom Arms Model 757, a Linebaugh Custom Sixguns Ruger New Model Blackhawk Bisley and a Ruger No. 1.

We became good friends, as we were both very enthusiastic about good sixguns and cartridges and over the next couple of years, we continued to correspond by both letter and long-distance phone calls. In July 1985, John Taffin and I each grabbed about a dozen favorite sixguns, several hundred pounds (not rounds) of ammunition, loaded everything up in his Ford Bronco and made the 600-plus mile drive from our Idaho homes to Cody (actually Powell) to meet Linebaugh along with his wife and two young sons. His remote log cabin was still in progress and it felt as though we had stepped back in time and I was immediately comfortable. There was no running water, so I helped haul water from the creek and slept comfortably on the floor at night. We spent the next few days shooting sixguns and discussing cartridges, loads and guns. Linebaugh asked if we thought it was feasible to build a .50-caliber sixgun cartridge, which we discussed at length and all agreed that it would be a most interesting gun and caliber. The next morning, Linebaugh walked into the front room (from his attached shop) with a dummy round that contained a steel bullet he had just turned on his lathe and was seated in a 348 Winchester case that had been cut to 1.4 inches in length. He simply asked, “What do you think of that?” In that same year, Ruger began offering the New Model Blackhawk Bisley, which offers an outstanding grip frame to handle heavy recoil and would become the basis for the first 500 Linebaugh.

Buffalo Bore Ammunition was responsible for introducing a commercial version of the 475 Linebaugh that could be chambered in Freedom Arms revolvers.

In 1986, I had the opportunity to test-fire the first 500 that featured a five-shot cylinder and pushed a .510- to .512-inch, 440-grain cast bullet to around 1,250 to 1,300 feet per second (fps) and was thereafter reviewed by another gun magazine. Linebaugh soon began receiving many orders and he was in business full-time. For a big-bore, heavyweight-bullet sixgun (figuratively speaking), the 500 is very potent and remains a favorite of this writer. The guns are not unreasonable in size or weight; rather, they are practical in every respect and can be readily carried on extended wilderness hunting trips that I have done many times while large Alaskan brown bears circled my tent or walked within a few feet of where I slept (or was trying to sleep) on the open ground with the powerful 500 strapped to my chest.

Shown for size comparison (left to right): 357 Magnum, 44 Magnum and 475 Linebaugh.

The problem arose in 1987, when Browning/Miroku offered a limited production run of the Winchester Model 71 rifles chambered in 348 Winchester. But soon thereafter, Winchester Ammunition announced that 348 ammunition would be discontinued, which made no sense. Regardless, without brass availability, the 500 seemed doomed, but today, Starline offers 500 and 348 brass and neither has the latter become obsolete.

Even with full-house loads, the 475 can deliver excellent accuracy using Hodgdon H-110 powder and cast bullets.

Linebaugh next considered the 45-70 Government case for a new cartridge, which was likewise cut to 1.4 inches and necked to accept .475-inch jacketed bullets, while the cast bullet diameter is .476 inch. Early experiments with the 475 Linebaugh resulted in poor accuracy, but after changes to the rifling twist rate, accuracy became excellent. It pushed 375-grain bullets to 1,450 fps or 420-grain bullets between 1,350 to 1,400 fps and proved to be an outstanding big-game hunting cartridge capable of taking the world’s largest game including Cape buffalo, hippo and elephant. The original Linebaugh wildcat handloads generally had an overall cartridge length of around 1.830 inches, depending on the bullet used (which I will discuss further in a moment). The first guns, again based on the Ruger New Model Blackhawk Bisley, were offered to customers in 1988, and soon, several other gunsmiths began building custom 475 Linebaugh five-shot revolvers, including Hamilton Bowen of Bowen Classic Arms that more or less codeveloped that cartridge with Linebaugh. While there was great interest in the 475, wildcat cartridges usually have limited general appeal.

Light and midrange 475 Linebaugh loads are still very potent while reducing recoil, but offer outstanding accuracy.

In 1997, I was contacted by Tim Sundles, who was attempting to set up an ammunition company that would offer both the 475 and 500 Linebaugh loads. However, the number of custom-built revolvers in these calibers was still rather small, so ammunition sales would be limited too. He knew that a production revolver would be important to change the 475 from wildcat to production status and generate enough sales to support the investment to tool up to produce ammunition. The problem was that Ruger was not interested in chambering a gun and the 475 cartridge was too long to fit into the compact cylinder of the Freedom Arms Model 83 revolver. Furthermore, the large rim of the 45-70 case measured .608-inch diameter and would not allow cartridges to chamber in the Freedom Arms gun, or in other words, the rims would essentially overlap.

I suggested a few significant changes to Sundles. First, the bullet nose length should be shortened from around .400 inch to .350 or .365 inch for a maximum overall cartridge length of 1.765 inches. The rim diameter should be made smaller, essentially changed from .608 inch to .545 inch maximum. The primer pockets should be changed from rifle primer size to large pistol. Sundles worked with Starline to make brass, which when it went into production, had a rim diameter of .540 to .542 inch (the latter figure being the current SAAMI specification). The next step was to have Custom Gunsmith Jack Huntington convert a Freedom Arms Model 83 to 475, which worked perfectly with the newly-designed bullets and modified case rim. At this point, I suggested to Freedom Arms President Bob Baker, that he at least consider this caliber, so he began conducting experiments with Buffalo Bore Ammunition and then began offering the 475 that would become known as the Model 757. I was sent the first revolver so chambered, which was a Premier Grade fitted with a 6-inch octagonal barrel and black Micarta stocks, which was thoroughly tested and reviewed in the June 1999, Guns & Ammo magazine.

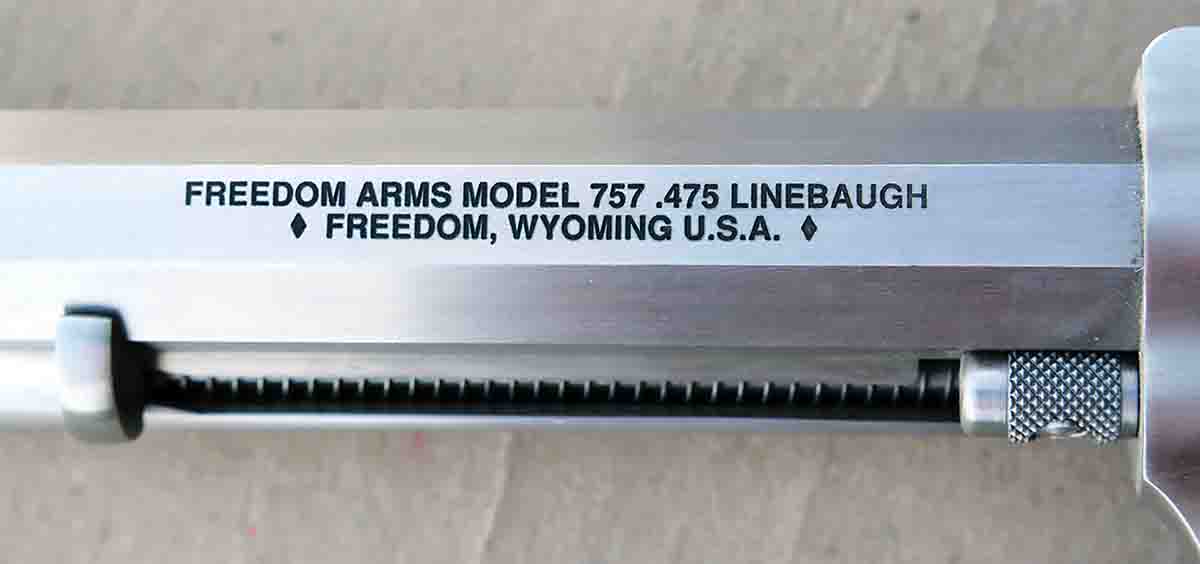

A Freedom Arms Model 757 chambered in 475 Linebaugh was used to develop “Pet Loads” data.

During this era, Sundles made an agreement with John Linebaugh that resulted in “475 Linebaugh” becoming a registered trademark of Timothy B. Sundles and prevented other ammunition companies from chambering this round. This ultimately resulted in the 480 Ruger being developed that is essentially a 475 case shortened from 1.4 inches to 1.285 inches. Suffice to say that the two share the same dies and bullets and the 480 can be fired in any 475 revolver, the same as 38 Specials can be fired in 357 Magnum guns.

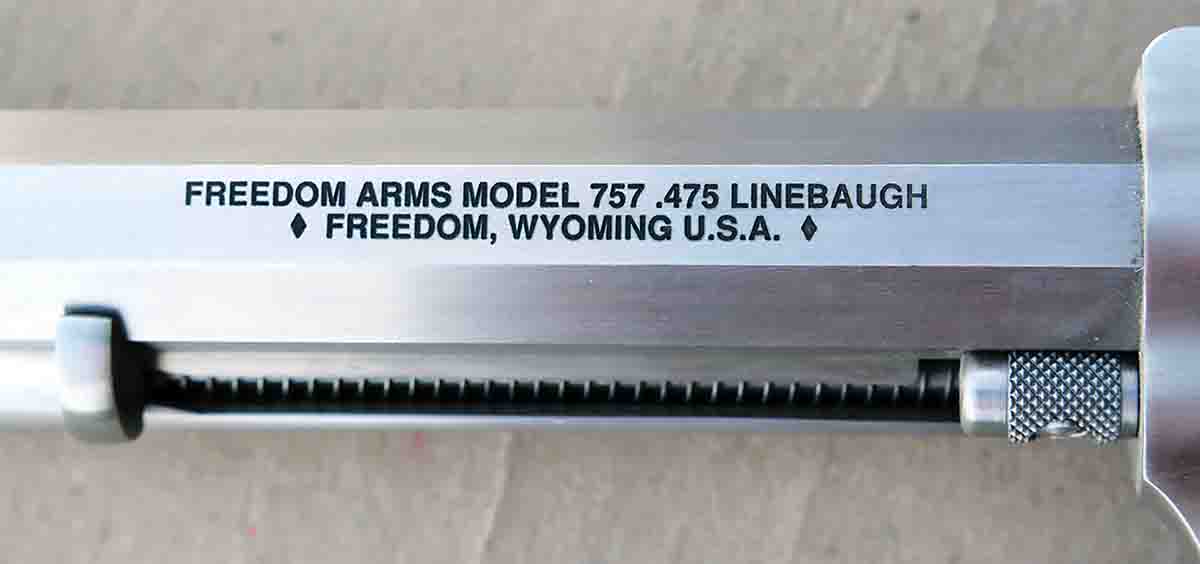

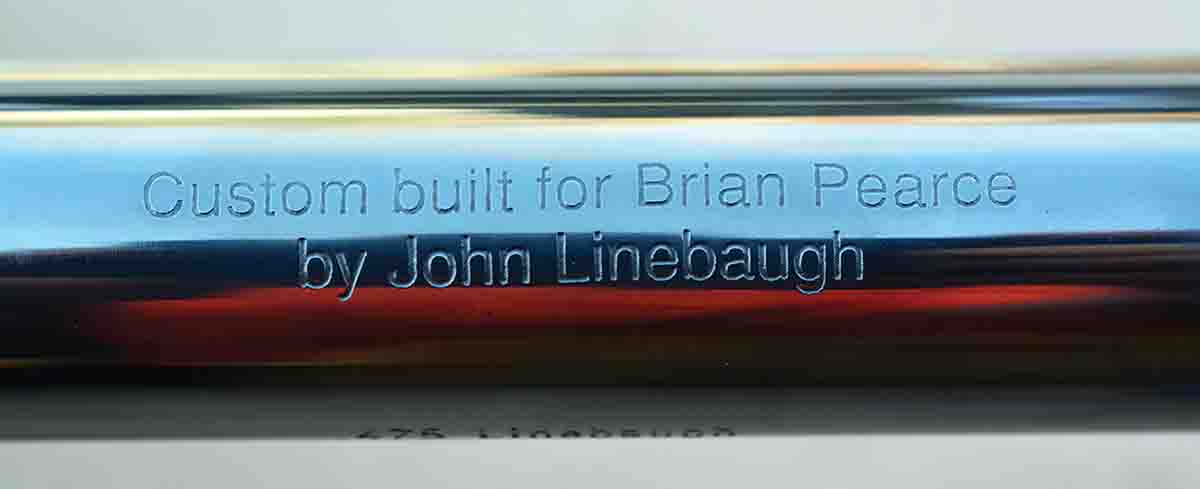

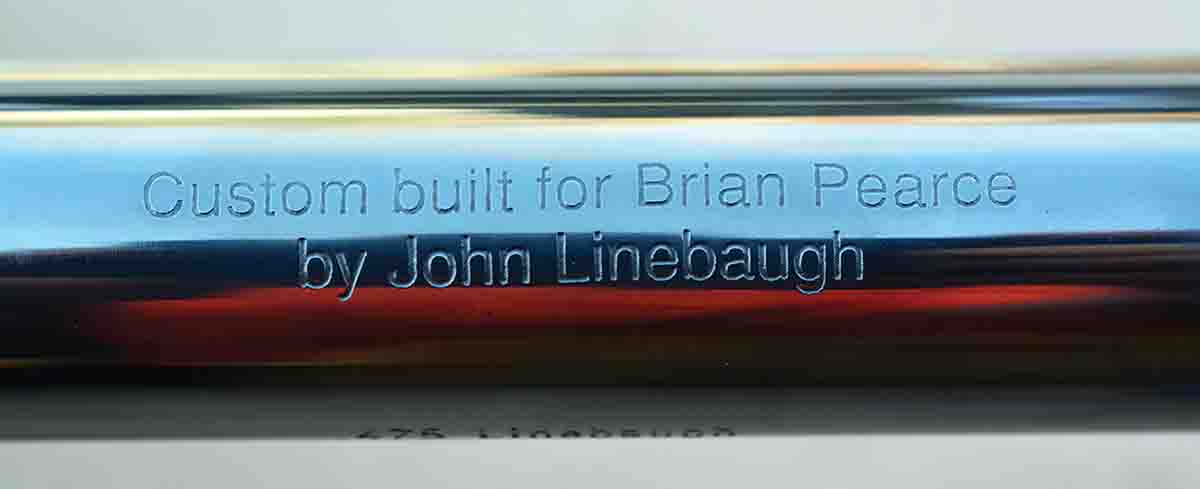

Brian cross-referenced 475 data in a Linebaugh Custom Sixguns Ruger New Model Blackhawk Bisley that was “custom built for Brian Pearce by John Linebaugh” many years ago.

For today’s 475 test guns, the previously mentioned Freedom Arms Model 757 Premier Grade with a 6-inch octagonal barrel was selected for the majority of the testing. This gun is super accurate and features properly-cut chambers, a throat diameter of .4758 inch, line-bored chambers and a good sight picture. It has produced many sub-1-inch groups with both jacketed and cast bullets. However, much of the accuracy testing was cross-referenced in a Linebaugh Custom Sixguns that was built on a Ruger New Model Blackhawk Bisley for this writer by Linebaugh many years ago. It features a 5½-inch barrel and all the extras including a perfectly tuned action, crisp trigger pull, custom sights, etc. When this gun was first acquired, it produced a five-shot group at 25 yards that measured just over a half-inch center-to-center, which proves the accuracy potential of the 475. Loads were also checked in a Ruger No. 1 to assure proper chambering.

Some bullets seat deep enough to cause a bulge in the midsection of the case, which can cause chambering problems in guns with minimum chamber specifications.

Buffalo Bore offers several 475 loads that include a pleasant midrange version featuring a 420-grain cast bullet at 950 fps, a 420-grain long flatnose (LFN) and a 420-grain wide flatnose (WFN) at 1,300 fps and a 400-grain jacketed hollowpoint (JHP) at 1,350 fps. Incidentally, several other ammunition companies more or less offer loads that duplicate these ballistics.

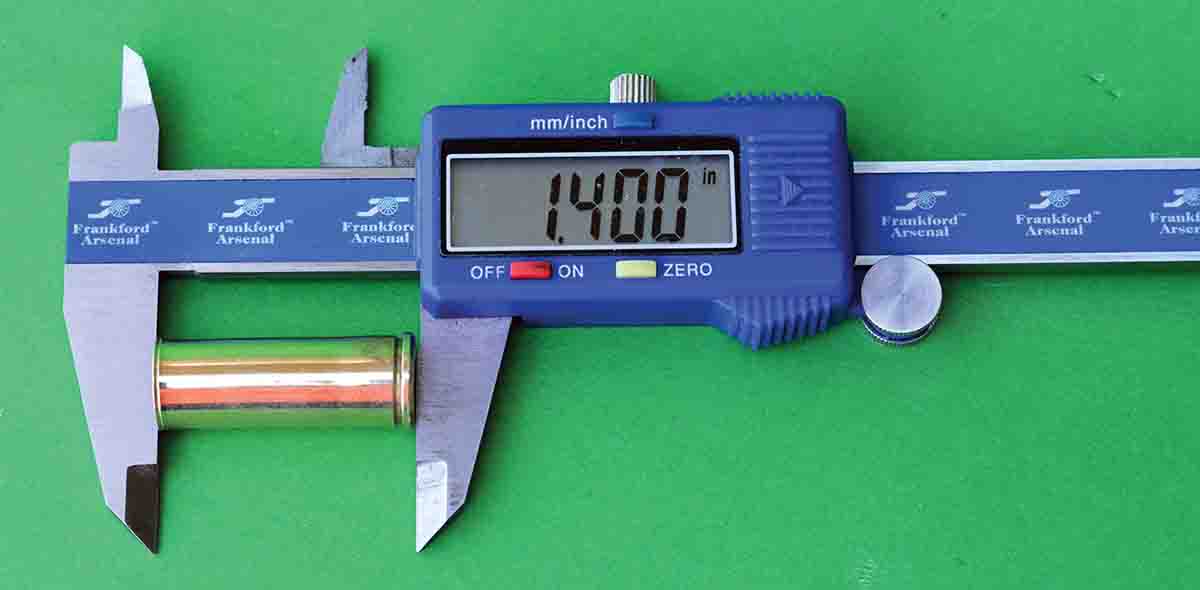

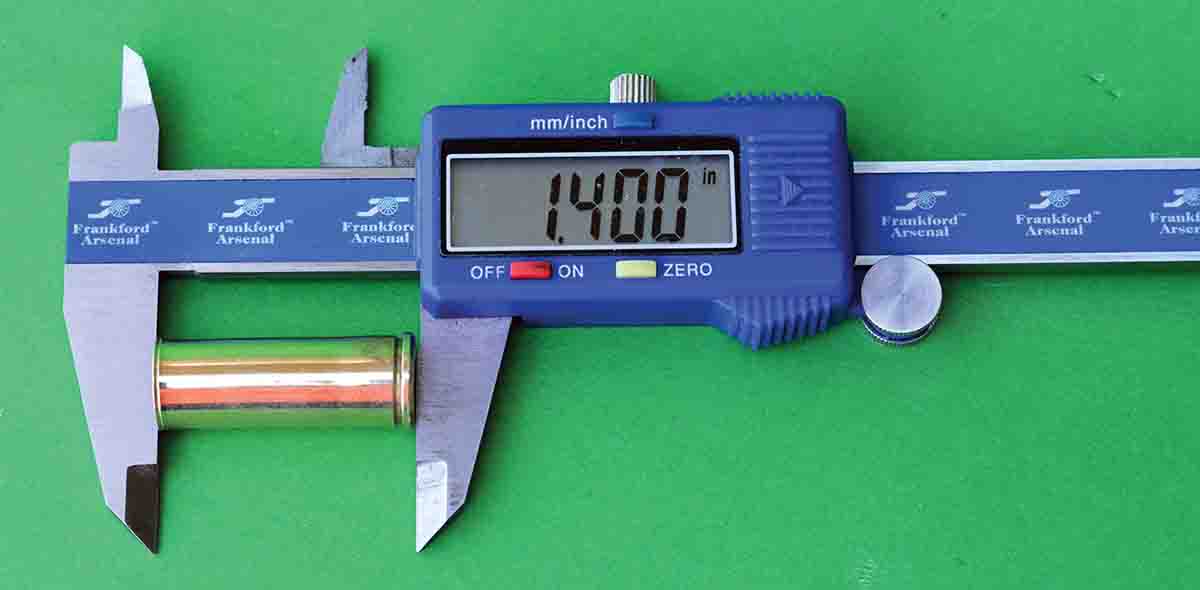

The 475 Linebaugh (right) is based on the 45-70 Government case (left) cut to 1.4 inches and the rim reduced from .608 inch to .542 inch.

Carbide dies are readily available for the 475, which are highly recommended to save time. Late 1980s-era special order RCBS dies were used to develop the accompanying data that include a carbide sizing die. Cases should always be full-length sized, followed by lightly chamfering the inside of the case mouth to prevent cast bullets from being “shaved” when they are seated. The expander ball should be at least .006 inch smaller than the bullet diameter, which is important to achieve a tight case-to-bullet fit and obtain a heavy bullet pull to obtain reliable powder ignition and prevents bullets from jumping crimp or walking out the front of the cylinder and tying up the gun during heavy recoil. Naturally, the crimp should be as heavy as possible. Both cast and jacketed bullets vary in regard to how much crimp they will allow. Most cast bullets feature a deep, beveled crimp groove; however, most jacketed bullets feature a cannelure and cannot be crimped as heavily. In this instance, a neck-down crimp should be considered, but this is not always possible with all die manufacturers’ seat/crimp die.

Jacketed and expanding monolithic bullets can perform very well in the 475 Linebaugh including the: (1) Barnes 275-grain XPB, (2) Hawk Precision 300-grain HP Bonded, (3) Speer 325-grain Deep Curl and (4) Hornady 400-grain XTP.

The 475 thrives on cast bullets, which can be used for loads as low as 800 fps without concerns of sticking a bullet in the bore, but are also ideal with the highest velocity loads that can reach more than 1,500 fps. When hunting, due to the large caliber of the 475, it delivers a heavy blow and tremendous shock to game, but also penetrates deep, straight and breaks through bone and penetrates dense muscle with ease. Neither does it need expansion to be highly effective. As to the accuracy, select bullets can offer outstanding accuracy and as indicated, can produce sub-1-inch groups at 25 yards.

Light bullet loads can offer high velocities if desired.

Space will not allow a complete discussion of cast bullets, but a few things should be mentioned to ensure that performance is top-notch. First, most readers will not be casting their own bullets; rather, they will purchase bullets from commercial cast-bullet companies. As indicated, if handloading for a Freedom Arms 757, choose a bullet with the correct nose length. The LBT-style bullets with a WFN design often feature an ogive (just forward of the case mouth) that is larger than the throat diameter due to how they are sized by the manufacturer. This is a problem, as loaded cartridges will often not chamber in guns with tighter throats. Those set up to cast their own bullets can simply size these bullets down in a Lyman H&I sizing die until they fit into the throat of a given revolver, which corrects the above chambering problems. While WFN bullets can offer very impressive performance on game and can be very accurate, they generally need to be loaded at fairly high velocities to properly stabilize, especially at longer ranges. Long flatnose and flatnose bullets with a more modest meplat that is generally 72 to 74 percent of caliber or less, will generally stabilize at a wider range of velocities – the same as most semiwadcutter (SWC) or Keith designs.

Cast bullets featuring a gas check and a plain base can each perform very well in the 475 Linebaugh.

Generally speaking, plain-base cast bullets can work very well with loads that range from 800 to 1,500 fps. For success at higher velocities, the bullet design should feature generously large grease grooves and have a quality bullet lube applied. They should be sized to correspond with throat and groove diameter (that is generally around .476 inch). For general use, Lyman No. 2 alloy with a 15 Brinell Hardness Number (BHN), or alloy with a similar formula, is preferred for high-velocity, full-power loads, however, light and midrange loads that typically range from 800 fps to 1,100 fps can enjoy accuracy benefits from alloys with a BHN of around 10 to 11. If the gun features a quality barrel with a bore that is mirror shiny and smooth, leading will be virtually nonexistent. However, some load and gun combinations will lead. In these instances, a bullet with a gas check will virtually eliminate the problem. With today’s data, cast bullets range in weight from 355 to 445 grains. I am especially fond of various 400- to 425-grain bullets for general purpose use. Incidentally, there is a very broad selection of cast bullets from commercial casting companies.

SAAMI maximum overall cartridge length is listed at 1.765 inches. However, select handloads exceeded this limit slightly, but worked perfectly in the Freedom Arms Model 757 revolver.

Maximum case length is 1.400 inches, while the suggested trim-to length is 1.390 inches.

Cast bullets were sized to .476 inch, while the jacketed bullet diameter is .475 inch.

Jacketed bullet selection is more limited. Soon after the 475 became an industry standardized cartridge, Speer began offering the 400-grain Gold Dot, while Hornady offered a 400-grain XTP. Both were excellent bullets; however, when the 480 Ruger appeared a couple of years later and was offered in the popular Ruger

Brian used a Freedom Arms Model 757 and a Linebaugh Custom Sixguns Ruger New Model Blackhawk Bisley to develop loads for the 475 Linebaugh.

Super Redhawk and other guns, the need arose for lighter-weight bullets, which resulted in a Speer 325-grain Deep Curl and 325-grain Hornady XTP. This resulted in both 400-grain bullets being discontinued. In addition to data for the 325-grain bullets, I have included data with the 400-grain Speer and Hornady bullets, as they are still available at gun shows and other sources. Incidentally, Hawk offers excellent bonded bullets weighing 265, 300, 350 and 400 grains, with data included for the 400-grain version with .035-inch jacket. Barnes offers its expanding monolithic 275-grain XPB that expands at velocities as low as 1,000 fps.

The industry maximum average pressure limit is 50,000 psi. None of the accompanying data exceeds that limit. It is noteworthy that many custom gunsmiths have built 475s, usually on Ruger New Model Blackhawk cylinder frames, but have used a standard factory cylinder size that has an outside diameter measurement of around 1.730 inches. For guns to be really suitable for full-pressure loads, in addition to the new cylinder being constructed from 4100 series chrome-moly steel, they should feature a larger cylinder diameter that is around 1.785 inches. This requires the cylinder frame window to be milled out to accept the larger diameter five-shot cylinder. If a converted revolver has the factory size outside cylinder dimension, it is suggested to limit loads to around 35,000 to not over 40,000 psi. This still allows potent loads that push 420-grain bullets to 1,100 to 1,200 fps with select powders. Another reason to limit pressures with guns with the factory cylinder size is that the unsupported barrel proper that can split with full-house loads.

Buffalo Bore Ammunition (left) was the first to offer commercially available ammunition for the 475 Linebaugh, while Hornady (right) followed suit.

In wildcat form, the 475 case (based on cut down 45-70 cases) utilizes large rifle primers; however, with commercially-produced brass from Starline (also cases with BBA headstamp), primer pockets were changed to correspond with large pistol rimers. However, Hornady utilizes a large rifle primer pocket with its brass. I have used large pistol primers in the Hornady case without a problem and without experiencing misfires due to the primer seating deeper than the industry standard of .005 inch maximum. Starline cases were used to develop the accompanying data, which are strong, robust and offer a long case life and are available factory direct (800-280-6660). CCI No. 300 Large Pistol standard primers were used primarily throughout that provided perfectly reliable ignition and uniform velocities.

The 475 thrives on the same powders that perform best in the 357, 44 Magnum and similar revolver cartridges. For full-power loads, notable performers include Hodgdon H-110, Lil’Gun, Accurate No. 9, No. 11FS, Alliant Power Pro 300-MP, 2400, Vihtavuori N-110, Winchester 296 and Ramshot Enforcer.

Popular powders commonly used in magnum revolvers gave top performance in the 475 Linebaugh.

The usefulness of midrange loads should not be ignored. Using cast bullets pushed from 950 to 1,100 fps results in potent loads that are suitable for taking big game, but often produce top accuracy, while substantially reducing recoil. Excellent powders for midrange loads include Hodgdon Longshot, Alliant Power Pistol, Unique and Accurate No. 7.

Light target loads are also potent and can be fired in volume by most shooters. Again, using cast bullets weighing 355 to 420 grains and pushed to 750 to 900 fps, these loads are still powerful and capable of taking big game at appropriate distances. Select fast-burning powders are not position sensitive, which is important in the 475’s large case, and accuracy can be very good. Examples include Accurate No. 2, Hodgdon Titegroup, Alliant Bullseye, Unique and Power Pistol.

The 475 offers remarkable power and accuracy and is housed in sixguns that are practical in size and weight for field use. Through handloading, it becomes much more versatile and useful.

* * *

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)