Cartridge Board

11.35x51R Danish

column By: Gil Sengel | February, 17

Ever since the advent of self-contained metallic cartridges, American riflefolk have had an insatiable appetite for obsolete (so-called “surplus”) military rifles. Many of these have been single shots chambered for big black- powder rounds. They were breechloaders adopted by countries hurrying to modernize their militaries beginning in the late 1860s. Their service with first-line units, however, was not long. Development of smokeless powders and smaller calibers in the 1880s quickly made them as obsolete as the percussion muzzleloader.

These rifles were not immediately discarded by their original owners. They went into storage as reserve or were issued to support troops. Eventually, though, most found their way to the U.S. surplus market, because the original countries were largely totalitarian or socialist/progressive and thus did not allow their citizens free ownership of arms. This did not apply to the U.S.

Our cartridge this time is one of these early rounds. Thousands of rifles chambering it came into the U.S. in the 1950s and ’60s. Most were in excellent to nearly unfired condition! The cartridge is the 11.35x51R Danish; its only rifle was the M1867 Remington rolling block. Therein lies an interesting tale.

In 1865 Denmark adopted a breech-loading conversion of its 17.5mm muzzleloader. It used an action designed by American Jacob Snider and was the same action used to convert Britain’s Enfield muzzleloaders a year later. The main difference was that Denmark’s cartridge was a rimfire and Britain’s .577 Snider was a centerfire.

Military cartridge development proceeded quickly, and the muzzleloader conversions firing .58- to .70-caliber rimfires didn’t last long. Lighter, smaller diameter bullets gave greater range, greater accuracy and less recoil. Denmark was immediately looking for a new rifle and cartridge.

At that time, while there were a lot of designs for breechloading rifles (all single shots), none had seen much, if any, combat use. Most existed only as inventors’ prototypes. The Danes had been suffering attacks from neighboring Prussia and wanted a proven rifle now, not some designer’s idea. They tried to purchase the American Peabody rifle, but it could not be delivered quickly enough, so the new Remington rolling block (aka, the No. 1) that was in production was approved. This was in April 1867 with 20,000 rifles of a total 40,000 to be delivered in six months!

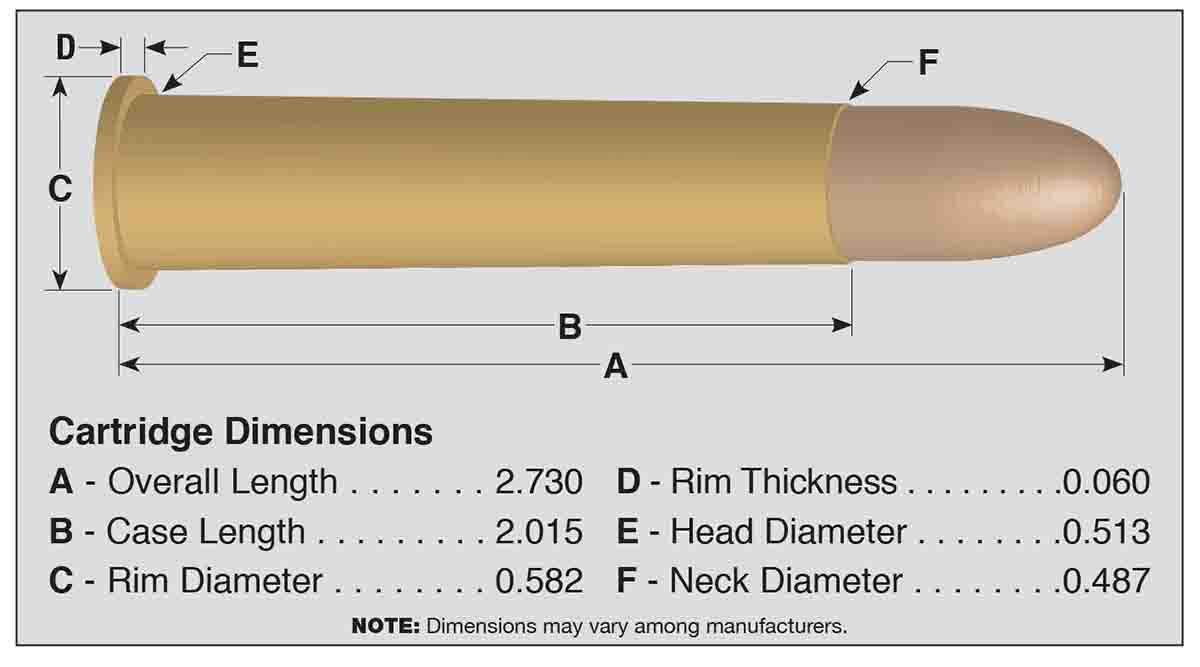

The cartridge for the Remington rifle has been given more than one designation. Perhaps most common are 11.7x42R rimfire and .45 Danish. The letter “R” in the name, indicating the round is rimmed, was added later, as at the time all metallic cartridges had rims. Remington called the rifles “45 caliber,” meaning bore diameter was .450 inch, about 11.4mm (.4488 inch). Groove diameter was .465 to .466 inch, or about 11.8mm. Bullets from ammunition measure about .460 inch, which is unimportant, since the exploding black powder would expand the slug to fit. The bullet was 385 grains of lead pushed to 1,250 fps by 60 grains of black powder.

The foregoing is important, because Remington didn’t deliver the rifles by the date specified by contract. Rather than pay a substantial late fee, Remington gave Denmark a license to make all the rolling blocks it wanted. This amounted to almost 40,000 rifles and carbines that are the guns that came to the U.S. on the surplus market.

These Danish rolling blocks were not, however, rimfires but centerfires, because in 1896 a centerfire version of the rimfire cartridge was supposedly adopted. It is rather strange that centerfire ignition was not used much earlier given the very real problems associated with large rimfire cartridges. It is also strange that Winchester catalogs show centerfire .45 Danish cartridges and primed centerfire empty cases beginning in 1879. That year’s catalog also lists a .45 Danish rimfire round. Centerfire cartridges were listed until 1910.

Even more strange is why upgrading the rolling blocks was even considered. Denmark had adopted the Krag-Jørgensen bolt-action repeater firing the 8x58R cartridge in 1889. This rifle was far superior to the old single shot. It does explain why so many of the rolling blocks were in nearly new condition.

At any rate, the 1896 round was longer than the rimfire, used the same bullet weight and diameter, but it was of jacketed design and was fueled by smokeless powder. This round is the 11.35x51R Danish. Some references call it the 11.7x51R.

Then there are other strange events. When developing the smokeless round, it was discovered that the German steel used for Danish-made rolling block barrels was stronger than the English steel used in the Remington-made barrels. Perhaps this was why only Danish-made rifles were converted to chamber the longer smokeless round. Also, the bores of the Remington barrels were larger (.450 inch/11.4mm) than those of Danish manufacture (.446 inch/11.35mm).

Some of the Remington rifles were converted to centerfire, but chambers were not lengthened. These fired a cartridge that was exactly the old rimfire, only in centerfire form. Thousands of these rifles were sold to Danish rifle clubs whose final owners often obtained rimfire breechblocks, so they could fire both centerfire and the older rimfire ammunition. None of these have been seen in the U.S.

Rechambering of the Danish- made guns was typical of such conversions. The rifle shown has a mint bore and chamber. The chamber is just a tapered hole out to the end of the leade. This fits a factory cartridge fairly well, yet a chamber cast looks like an icicle. The smokeless round supposedly pushed its 380- to 387-grain (references vary) jacketed bullet 1,350 fps.

Unfortunately, surplus 11.35x- 51R ammunition is long gone, and while both Remington and Winchester were said to load a commercial round, it’s not listed in my catalogs. At the time the rifles were being sold in the U.S., some ads stated they would “fire 45-70 shells.” Such is true as both 405- and 500-grain bullets in .45-70 cartridges will chamber, but firing such would not be a good idea. A chamber cast of the rifle yields a case diameter just forward of the rim of .522 inch. Pre-World War II .45-70s run about .505 inch, and newer ones are often .500 inch or less. This would result in too much expansion for a .45-70 case; it would soon (if not on the first firing) crack at the case wall/web junction. Old military 11.35x51R rounds measured about .514 inch.

Not long ago handloading this cartridge was nearly impossible, because the necessary case swaging and re-forming was beyond the capability of ordinary loading tools. The current popularity of obsolete British big-game rounds, however, has made .375 Flanged brass available once more. From this, 11.35x51R brass can be easily made. It is expensive, yet only 20 or so are needed. Bullets can be heavy (300 grains or more), cast .45 Colt slugs paper patched up to .465 inch, the groove diameter of the Danish barrels. Loading data is nonexistent, but data for the .45-70 Springfield trapdoor would serve perfectly.