Mike’s Shootin’ Shack

Cartridge Case Prep

column By: Mike Venturino - Photos by Yvonne Venturino | April, 24

Because my handloaded modern cartridges shot well with a simple case resizing, case neck expander and/or case mouth belling, I thought such brief time spent on case prep was sufficient for all handloading. Brothers, let me tell you this, a “lick and a promise” on cases to be used for precision handloads is not going to put you in the winner’s circle regardless of the exact shooting sport.

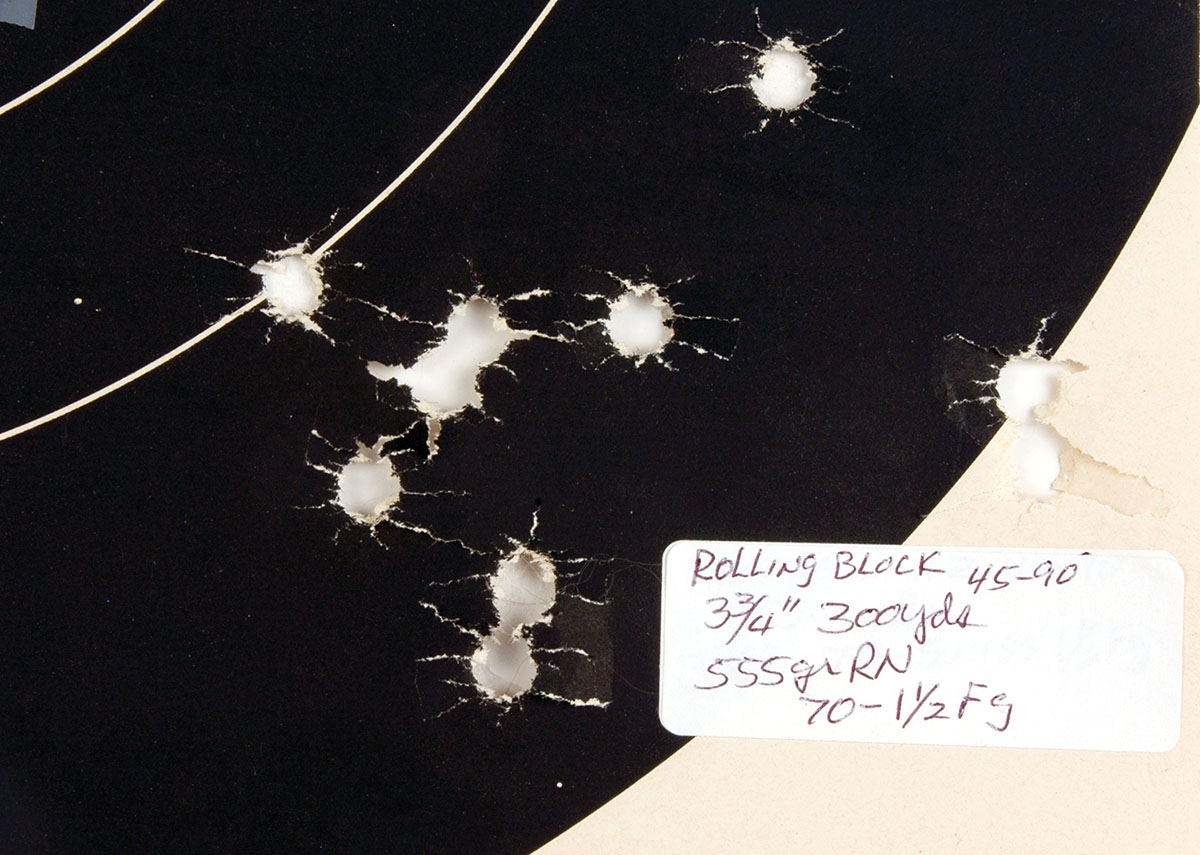

The BPCR game’s steel silhouettes were set at ranges of 200, 300, 385 and 500 meters respectively for chickens, pigs, turkeys and rams. Here’s one example: in order to be competitive, a BPCR must reliably group into a circle no larger than 11 inches at 385 meters (422 yards) for turkeys. That’s keeping all bullets on the turkey’s body as neck and leg hits are mere luck. The following are my basic rules of case prep for the best quality handloads for the BPCR Silhouette sport, but I dare think they would be applicable for any competition that relies on handloaded ammunition. Also, let me stress that I did not dream up these case prep rules all by myself. The techniques were borrowed collectively from other shooters who consistently scored higher than me and were willing to share.

First, I try to buy my brass in lots of 500 new cases. Nowadays, it’s hard to get that many cases at once, so if various lots are needed, a few from each lot should be weighed. If they do not vary significantly all should be well. Next, give each case a brief inspection as you may be surprised at how many defective ones will show up in regard to rim thickness or creases in case walls. Final touches include uniforming the primer pockets so they are level, reaming flash holes and trimming cases to identical lengths. After all this, I would still only use those new, unfired cases for practice or monthly matches. To me, they benefit from fireforming.

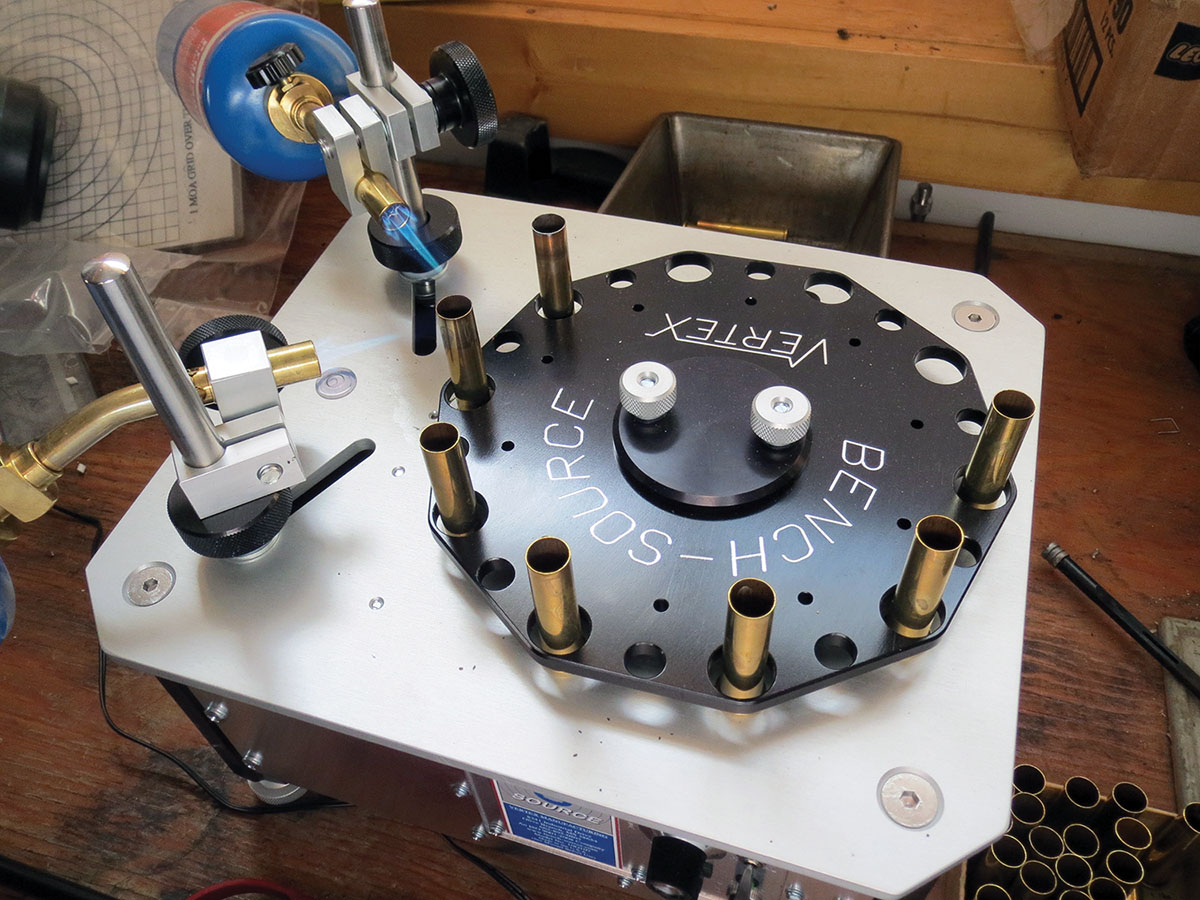

The next step is annealing, and I mean annealing before every reloading. This doesn’t mean heating them red-hot and quenching them in water. For my purposes, the cases are heated only enough so that they change color. Some will say such light heating does not affect case hardness. All I can say is that when I began annealing for every loading, especially after acquiring the shown Bench Source Annealing Machine, my scores improved.

Another step done for every reloading is case trimming. This might sound excessive but I have learned through experience that cartridge cases do not stretch consistently. For example; with new 45-70 brass, I trim to 2.950 inches. After firing, some cases will merely be touched by the trimmer’s cutter while others might have lengthened by .002 to .003 inches. Of course, case mouths should then be chamfered and deburred lightly.

The next to last step is case mouth belling for cast bullets. There is a fine line between too much and not enough. Too much mouth belling can result in bullets seating crooked. Too little bell will result in lead shaved from the base of the bullet and/or sides. A fellow who wishes to remain unnamed showed up at a Montana match with case belling plugs of his own make. They have threads to fit into Lyman M-Die bodies. Those plugs allowed bullet bases to start but in no way could excessive case mouth belling occur. Bullets had no choice but to seat straight.

Case prep as described is time consuming. But, as I consider myself a handloader instead of a reloader, it is time well spent.