Reloader’s Press

Nosler Factory Seconds

column By: Jeremiah Polacek | April, 24

These days, prices for goods have drastically increased from items in the store to vehicles and housing. With no end in sight and 2024 being an election year, the hopes and dreams of saving money on ammunition may seem to be nearly hopeless. While some handloaders may laugh at the statement of saving money, it can be a viable reason to handload your own ammunition. There is no doubt that it can save money. The main issue in the savings department is that we tend to shoot a lot more whether it’s for load development reasons or simply because we prefer to burn that savings in the form of more powder and lead.

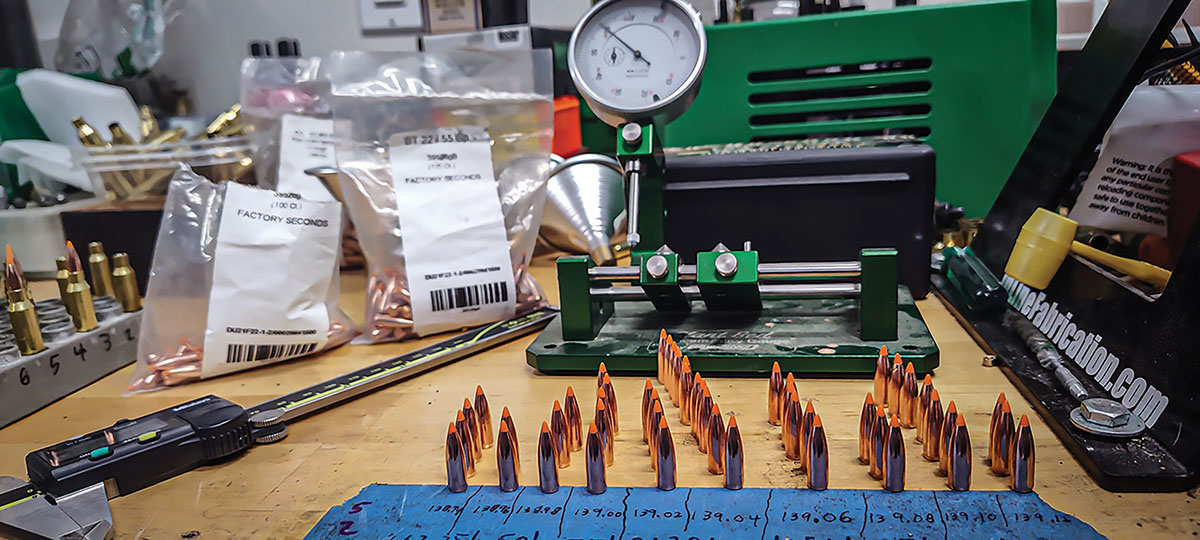

Saving money may be a fruitless endeavor for those of us who are addicted to tinkering with cartridge cases, powder and bullets. However, at the very least, you’ll be able to shoot more with the money you have. This brings us to our subject, Nosler factory seconds, these are cosmetically blemished cases, bullets and even factory ammunition. These are available through Nosler’s outlet website Shooters Pro Shop, where factory seconds can be picked up at a fraction of the cost of regular components.

What are these factory seconds though, and how do they perform and compare to factory firsts? That is exactly what we wanted to put to the test, however, due to the limited availability of components, some creativity was required. The first order of business was selecting test rifles, something that would represent real-world hunting and shooting so the tests could be easily duplicated. Four rifles were selected for testing, three of them being Nosler rifles and the other, a custom AR-15. All of these rifles have a pre-established baseline of accuracy using factory first components. This makes them great platforms for testing these factory second components.

The first rifle is a Nosler M48 chambered in 22 Nosler with a 24-inch barrel and topped off with a Leupold VX-5 3-15x 44mm scope. Plenty of factory ammunition and handloads have been assembled in this rifle in addition to being a favorite rifle for varmints. The next rifle is a Nosler M21 in 308 Winchester with a 22-inch barrel and a Leupold VX-5 3-15x 44mm optic. This rifle is also capable of ¾-MOA depending on the load used. A Nosler SR-30 ALTi suppressor was used throughout testing as well to make things more civilized for the shooters’ ears. There is a load development video on Handloader TV featuring this very rifle. The last Nosler rifle used for testing was another M48 but chambered in 280 Ackley Improved with a 24-inch barrel. A beautiful piece of wood with sleek custom knurling on the bolt knob and a Leupold VX-III 3.5-10x 40mm scope topped off this factory custom rifle. Lastly, a custom AR-15 with a KE Arms, KP-15 lower receiver and a Proof Research 20-inch barrel was thrown in the mix. This rifle is topped off with a Tract Toric 4-20x 50mm scope. It is the most accurate AR-15 in the vault along with it being an extremely popular cartridge when it comes to handloading. This rifle is capable of ¾- to 1-MOA with a good load and will also serve as the base of comparison between factory firsts and factory seconds.

Due to the limited availability of components, a creative testing procedure was laid out. The majority of testing between factory firsts and factory seconds would all be conducted in a single rifle. The custom AR-15 was used and testing would include only one variable at a time. Switching from factory firsts then seconds and different combinations of the two as laid out in the accompanying table. Then the three Nosler rifles would include handloads with factory first and second components. This was done simply to establish a baseline of comparison across different components and different cartridges and allow for the inclusion of some “blemished” factory ammunition as well.

With the test criteria laid out and load data compiled and a logbook assembled to record the results, it was time to spend some time at the bench. Time at the reloading bench equals accuracy downrange. We are testing the components here and not the tools used to make the ammunition, things needed to be consistent and repeatable. To accomplish this, an Area 419 ZERO Reloading Press was used to assemble all loads. Redding dies were used throughout testing for sizing and bullet seating operations. All cases were chamfered and deburred on an RCBS Brass Boss, the factory second cases from Nosler are not pre-prepped like their factory first premium cases. All primers were seated with an RCBS Automatic Priming Tool, a favorite of mine when seating primers for multiple cartridges in a single session at the bench. Lastly, all powder was dispensed and weighed on an RCBS MatchMaster Powder dispenser to ensure charges were consistently within .04 grains of each other.

With logbook and loads in hand it was time to start testing, over the course of a couple days all loads were shot and recorded. This was necessary to keep the environmental conditions as consistent as possible during the test. Initial results were quite impressive to say the least, a small portion of this test was filmed as well (more details at the end of this article). The 22 Nosler did not disappoint in assembling a roughly ¾-MOA group with the factory firsts and seconds. The Nosler M21 in 308 Winchester also produced impressively-equal results with firsts and seconds. The 280 AI Nosler custom rifle also produced similar results across the factory firsts and seconds. Although the group was a little larger than expected, the velocity was also lower than usual. This was also the only test group where I was forced to use a different lot of powder than what was used in previous tests to develop this load. This particular lot of Reloder 22 seemed much slower than in previous tests and may be the result of the larger group. Nevertheless, the results were consistent from factory seconds to firsts.

This brings us to the AR-15 tests in which the table tells us the whole story. The long and short of it is that there was little to no discernable accuracy difference between the factory firsts and seconds in terms of dispersion. In addition to testing the accuracy, expansion was also tested while out hunting. A trip to the Spur Ranch in Wyoming allowed for plenty of opportunities to test the terminal performance and effects of the varmint bullets on prairie dogs to ground squirrels. The bullets still performed as they were designed. Of course, this is not a perfectly scientific test for terminal performance, yet it is an accurate real-world representation of what to expect.

While in Wyoming, a couple hundred rounds using factory seconds connected with tiny alfalfa-eating pests with explosive results. The results were indistinguishable from the factory firsts to the seconds. A coyote was also taken using factory second Nosler 55-grain Ballistic Tip Varmint bullets. The coyote did not seem to be able to distinguish a difference nor could I upon inspecting the damage inflicted from a single shot. Nosler stated that these bullets will perform just like the factory firsts in terms of accuracy and bullet performance. These tests certainly seem to confirm that. This makes them a great way to save money and shoot more. Nosler is clearly only selling bullets that are cosmetically blemished and these blemishes do not seem to affect performance. In closing, testing indicated that the Nosler factory seconds are good enough.

.jpg)