Rifle Die Design

Tips for Enhanced Accuracy

feature By: John Barsness | August, 19

To explore this concept, first look at the design of the basic dies many companies make. The basic case-sizing die, whether full-length or neck only, features an inside “spindle” that screws into the top of the die. The spindle includes a decapping pin to push out fired primers, held in place by an expander ball that screws onto the lower end of the spindle, tightening a collet that holds the pin in place.

This system has several virtues, including simplicity, the reason basic dies are so “affordable.” However, it can easily result in case necks misaligned with the case body. Crooked necks hold bullets at a slight angle to the bore, so they leave the muzzle pointing in slightly different directions. This does not enhance accuracy.

This misalignment can occur for three reasons. First, almost all expander “balls” are actually cylinders, more or less tapered on the ends, and the cylinder may be misaligned with the centerline of the die. Second, many case necks are thicker on one side than the other. Both tend to result in the expander ball pulling the neck sideways. Third, during resizing, the case’s rim is held in a case holder. Unfortunately, the standard case holder only loosely holds about half of the rim. This can allow the case to tilt while being pulled over the expander ball, because in a basic sizing die the ball sits near the bottom. By the time the neck slides over the expander ball, the case is almost out of the die.

Several techniques can solve this problem, if you so desire. Believe it or not, some handloaders do not care whether their big-game rifle shoots sub-inch groups. However, many handloaders become obsessed with shooting tiny clusters of bullet holes.

The primary tool for fixing neck misalignment is a concentricity gauge, a pair of V-blocks equipped with a dial gauge accurate to .001 inch. To check whether the necks of resized cases align with the case body, place a sized case in the V-blocks, set the pin of the dial just behind the case mouth, then spin the case with your fingers. If the dial indicates more

Years ago, I was invited by a major rifle and ammunition company to field-test a newly introduced 7mm magnum cartridge on a New Mexico pronghorn. Prior to the hunt, the company shipped me a rifle and some “factory” ammunition, but unfortunately the rifle averaged close to 3 inches for three-shot groups at 100 yards. This occurred because no factory ammunition had yet appeared, so they handloaded some, and the expander ball of their sizing die pulled the case necks way out of alignment. The run-out of the seated bullets ranged up to .010 inch, which in a big-game cartridge compares to the Leaning Tower of Pisa. By selecting the straighter rounds, I finally got the rifle to group around 2 inches. Most hunters think this is inadequate for antelope, but I managed to kill a buck with one shot at 200 yards anyway.

I perform a run-out test with every new set of basic dies, and about half result in necks with at least .003 inch of run-out. So why do die makers use the expander-ball system? The necks of rifle brass vary in thickness. If we squeeze the necks down without expanding them afterward, thicker-necked cases will hold bullets too tightly for decent

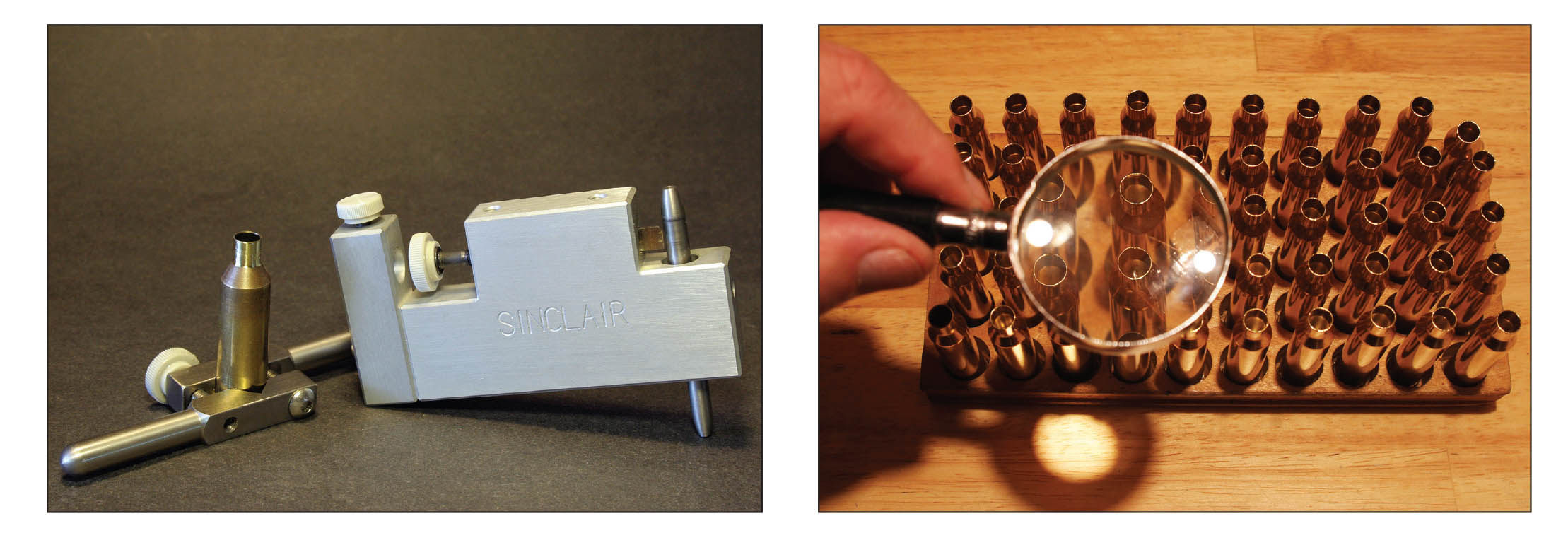

Several methods can ensure case necks have uniform thickness. They can be measured with gauges – and at least one concentricity gauge, the RCBS Casemaster, includes a neck-thickness function, but for most hunting handloads, simply looking down at the case mouths with a magnifying glass reveals necks thicker on one side than the other. With either method, a handloader can sort cases for uniform necks, or lathe-turn the necks to a consistent thickness. Luckily, these days, neck thickness is often very consistent, as demonstrated in my article “New Brands of Brass” in Handloader No. 319 (April-May 2019).

With cases of uniform neck thickness, basic dies can be adjusted to reduce or even eliminate neck run-out. First, remove the expander/decapper spindle from the die and tighten the threaded end in a drill motor. Spinning the

spindle instantly reveals whether the expander ball is straight. If not, it can be tweaked with pliers until it spins without any visible wobble.

Some dies will resize necks straight if a rubber washer is placed between the die and the locknut at the top of the die. This allows the spindle to flex slightly while the expander ball is pulled through the case neck.

A slightly more time-consuming technique is to resize cases with the spindle removed, then replace the spindle and press the case up into the die until the neck slides over the expander ball. This method works because the case head is firmly and squarely supported by the bottom of the case holder, rather than held loosely by the rim.

Yet another solution is to raise the expander ball much higher inside the die, ideally to the point where most of the case neck remains inside the neck portion of the die as it starts over the

In Lyman and RCBS sizing dies, the expander ball can normally be raised just under the neck portion of the die. In Redding dies it often refuses to go that high, but usually gets close enough to result in straighter necks.

However, the downside of raising the expander ball in basic dies, or pushing the case upward over the ball, is the decapping pin never even approaches the fired primer. This is solved with a separate decapping die (I use Lee Precision’s die), one of several reasons I like turret presses. Screwing a decapping die into the hole next to the sizing die makes punching out the primer quick and easy.

Another solution is to buy Forster dies. They normally cost more than twice as much as basic dies, but if various brands of brass are used when loading a certain cartridge, a Forster sizer can definitely save time and effort. I load a lot of .308 Winchester rounds with different cases, because my wife and I own several .308s and it helps to “identify” the ammunition for each rifle by using a different brand of brass. Consequently, my .308 dies are Forsters.

Some dies compress the necks of fired cases enough to hold bullets, rather than bumping up the neck with an expander ball. Sometimes this even occurs by chance with a particular basic die and batch of brass, but as far as I can recall, this happy coincidence has occurred twice out of the hundreds of dies used over the years. However, some companies will hone the neck portion of the die to the right diameter for a particular batch of brass, though this obviously works best only with brass of the same neck thickness.

The most common method of downsizing necks involves a removable “bushing” inside the neck portion of the die, a short cylinder with a round hole in the center. This works well for the same reason as pushing expander balls through necks. The bottom of the shellholder supports the case squarely, preventing tilting as the bushing slides down over the neck.

One phenomenon I recently noticed, in a duh sort of moment, is that bottlenecked cases with considerable body taper usually end up straighter when sized with bushing or collet dies, while cases with very little body taper often end up very straight when full-length sized in a basic die.

This flash of belated insight occurred when loading a considerable amount of ammunition for my pair of .22 Hornets for spring ground squirrel shooting. The rifles are a .22 Hornet Ruger No. 1B and an old BRNO bolt-action rechambered to the “improved” K-Hornet.

The Ruger is very accurate, but it took a while to find out because I started with basic dies. The results seemed to confirm the common opinion that the .22 Hornet is not an “inherently accurate” cartridge.

However, one year I decided to test one of the original Lee Loaders, a simple hand tool that is still the cheapest way to start handloading. In fact, I started with one for my first centerfire rifle, a military-surplus 7.62 Russian Mosin-Nagant. Lee Loaders are probably the slowest way to handload because each case gets tapped into the sizing die with a wood mallet, then tapped back out again with a rod – and the same tapping is used for decapping, priming and bullet seating. However, the design essentially follows the precision hand tools used by benchrest shooters, though benchresters usually use arbor presses rather than wood mallets.

I loaded 20 fired cases with the same bullet, powder charge and primer that had proven most accurate in the rifle, and started shooting. As the freshly cleaned bore acquired some fouling, the groups started shrinking.

So why had the rifle never grouped like that before? The reason was simple: Lee Loaders result in very straight cases. With basic dies, tapered Hornet cases tended to end up with slightly crooked necks because they can tilt quite a bit inside the sizing die – and it doesn’t take much in the tiny cases to result in bigger groups. However, while Lee Loaders make fine ammunition, they cannot make it fast enough to feed my rodent rifles. I ordered a Redding type-S die, which solved both problems.

The K-Hornet showed up in 2015 on the used rack at Capital Sports & Western Wear in Helena, Montana, and included a set of old CH basic dies. Based on my experience with the Ruger .22 Hornet, I was doubtful about the dies but was pleasantly surprised. Resized cases had very straight necks. I eventually realized the shoulder of the .22 K-Hornet is less than .01 inch smaller in diameter than the base just in front of the rim, so the cases cannot tilt very much inside the resizing die.

After some more thinking (which took a while, but resizing hundreds of Hornet cases takes a while), I realized this might be the major reason many handloaders find the .22 K-Hornet more accurate than the standard Hornet. The usual suggestion is K-Hornet cases “headspace” more consistently on their sharp shoulder while standard Hornet cases headspace on the rim, which can vary in thickness. While consistent headspacing can certainly affect accuracy, most handloaders use basic dies, which tend to size K-Hornet cases straighter than standard Hornets.

This is probably another reason many modern cartridges are considered more accurate than older, tapered rounds. Certainly the shorter, fatter powder columns and sharper necks of the 6mm PPC, 6.5 Creedmoor, .300 WSM, etc., promote consistent headspacing and powder burn. However, like the K-Hornet, their shoulders are almost as wide as their bases, allowing cases very little room to tilt inside a full-length sizing die.

Even with straight case necks, seating dies can also have a considerable effect on the straightness of loaded rounds. The basic seating die simply pushes bullets into a generic “spitzer” seating stem. As a result, unless the seating stem’s cavity fits the nose of a particular bullet well, the bullet can tilt a little while being pushed into the case neck.

Many companies also offer seating dies with sliding sleeves just slightly over case or bullet diameter to keep everything aligned correctly before the bullet even contacts the seating stem. Sometimes these features are only included in “competition” or “target” dies, but the seating stem of standard Hornady dies is an extended alignment sleeve. Combine a bullet-fitting stem with an alignment sleeve, and bullets pretty much have to slide precisely into straight case necks.