.270 Winchester

Testing a Vintage Load

feature By: Terry Wieland | October, 18

The very first “Pet Loads” article appeared in the May 1966, issue of Handloader. The writer was Ken Waters and the subject was the .270 Winchester. As it was originally formulated, “Pet Loads” was intended to compile the favorite combinations of well-known authorities – loads they had found to be particularly effective.

At the time, the best-known proponents of the .270 Winchester were Jack O’Connor (then Shooting Editor of Outdoor Life) and Colonel Townsend Whelen. By 1966 O’Connor had pretty much settled on H-4831 as the powder for the .270, propelling a 130-grain bullet (his favorite weight). It delivered high velocity combined with excellent hunting accuracy.

Hodgdon’s 4831 appeared on the market in 1950. Before that time, however, O’Connor had embarked on a marathon session of loading, shooting and reloading in an attempt to find the very best handload for the .270. The powders then available to him were the IMR series of 3031, 4064, 4320 and 4350. During a year in which he tried them all and fired a reported 10,000 shots in the pursuit of his ultimate load, O’Connor determined that the most accurate was 49.5 grains of IMR-4064 with a 130-grain bullet.

This load, he reported in Outdoor Life (and repeated in several books), was not only accurate in his own two custom .270 test rifles but had also proved to be very accurate in every .270 rifle he tested it in. It simply never failed.

In his article in 1966, Ken Waters concentrated on O’Connor’s H-4831 data and gave only passing mention to the old IMR-4064

load, but he did say that its “chamber pressures are well under 50,000 psi and velocities right around the 3,000 fps mark.” He also noted that Col. Whelen had success with this “old, much-tried prescription” but had moved on to IMR-4350 because it delivered greater velocity.

Given the .270 Winchester’s case capacity and its later success with H-4831, which is the slowest-burning powder of those mentioned, it would seem logical that the best combination in the years before H-4831 became available would have come with either IMR-4350 or 4320. However, O’Connor did not get the accuracy he wanted with 4350 and he found that in his .270s, IMR-4064 proved to be slower burning than 4320. This conclusion is contrary to every burning-rate chart I have ever seen, but he arrived at it by comparing powder charges with the resulting velocities. It’s difficult to argue with that.

With H-4831, originally known as “4350 Data Powder,” O’Connor achieved both excellent accuracy and velocities pushing 3,200 fps, a significant increase over 4064. He apparently never looked back, at least for hunting loads.

The comment that stuck in my mind was the one about the IMR-4064 load working well in every single .270 he tried. In my experience, a load that is excellent with one rifle may be mediocre in another, and no load ever proves to be accurate with every rifle. Note that he did not say equally accurate, but

that’s quibbling. Finding myself with a selection of different .270 Winchester rifles on hand for one reason or another, this was a good chance to test this one out.

There was, however, one hitch: Nowhere, in any modern loading manual that I could find, is this charge listed. Hodgdon, which now supplies IMR powders, lists a maximum on its website of 47.5 grains of 4064 with a 130-grain bullet. Most manuals ignore good old 4064 completely, while even such “intrepid” manuals (Dean Grennell’s phrase) as Lyman Reloading Handbook, 45th Edition (1970) stop at 49.0 grains. Speer’s Manual for Reloading Ammunition Number 6 (1964) also draws the line at 49 grains.

Obviously, this load needs to be approached with caution, especially given the many changes that have taken place in the 70 years since it was first published. Particularly, .270 Winchester brass from different makers varies widely in capacity. If O’Connor used Winchester brass, which has significantly lower capacity than most other brands, he would naturally have higher pressures, higher velocities and possibly better accuracy as a result.

The brass I used is Nosler, which has notably greater capacity than Winchester brass I have measured. For bullets, I laid in a supply of Sierra 130-grain spitzer boat-tails, a highly accurate bullet that I have used for both hunting and target loads.

Being a careful sort, I decided to work up from 46.5 grains to 49.5, chronographing as I went along, and checking carefully for any sign of excessive pressure. My test rifle was a Sauer 404, a strong, modern design that has delivered fine accuracy. At no point in the proceedings was there even the faintest hint that I was working on the fine edge of excessive pressure. Primers looked perfect, the brass showed hardly any sign of expansion, bolt lift was silky, extraction was effortless and the velocity never once hit 3,000 fps.

To be on the absolute safe side, I then repeated the process using a different rifle, working up but checking only for pressure signs. The results were identical; no pressure signs, no difficulties, no red flags.

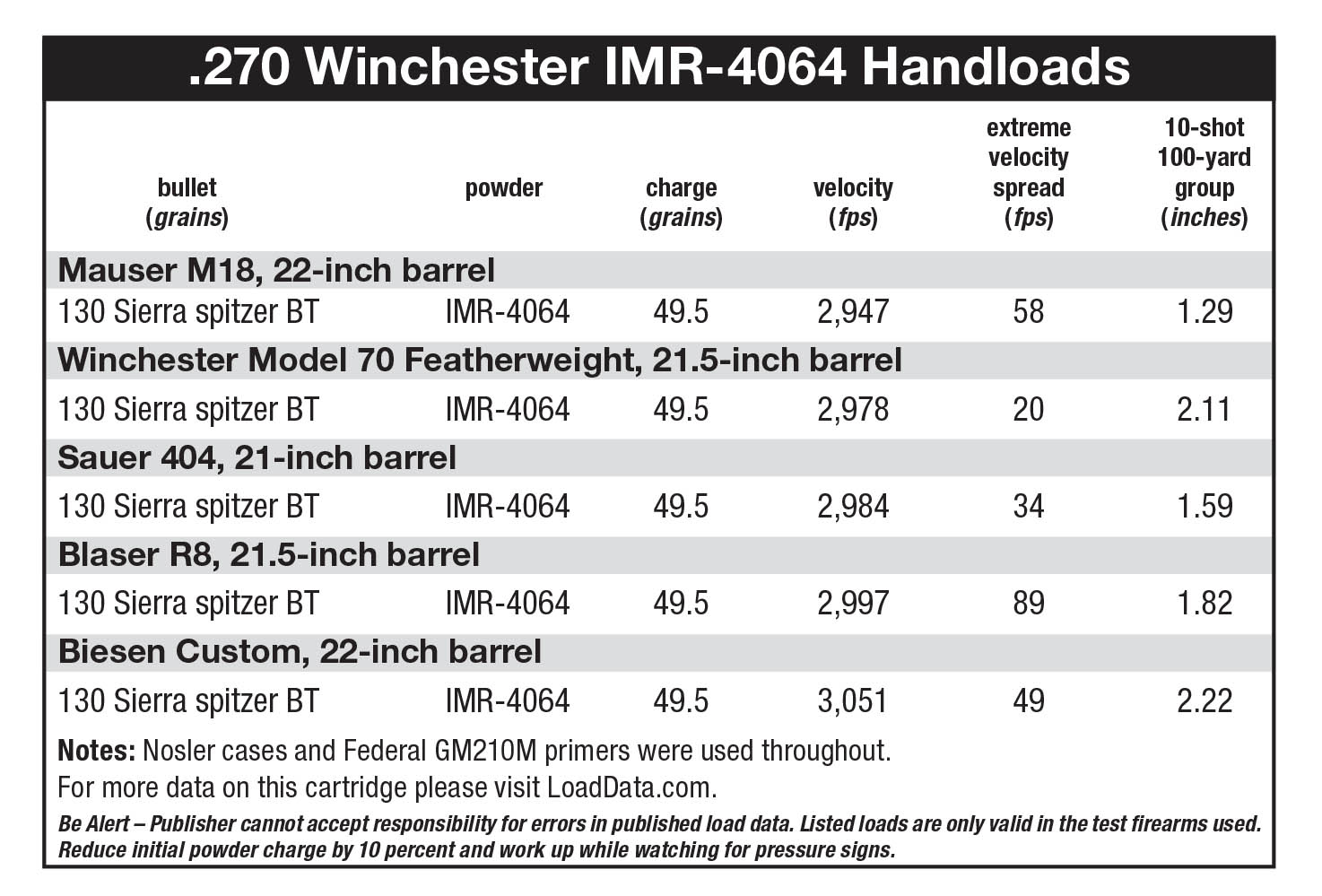

The five rifles I then used to test for accuracy using the 49.5-grain charge represent a cross-section of old and new, but all have proven highly accurate with one load or another. They included the aforementioned Sauer 404 plus a Blaser R8, a new Mauser M18, a new Winchester Model 70 Featherweight and a custom rifle built by Al Biesen in the 1980s on an FN Deluxe Mauser action. Barrel lengths were all in the 21- to 22-inch range.

This latter fact is significant because the early references to the load by O’Connor and Waters are not specific about barrel length. Presumably they were chronographing using 24-inch barrels; shortening by 2 to 3 inches would reduce velocity by 50 to 100 fps.

The test was simple: One 10-shot group at 100 yards with each rifle. All were fired the same afternoon, and the only concession made was to divide the shooting into two sessions, giving each rifle a few minutes to cool between five-shot strings. I also chronographed the load in each rifle.

The manager of the Top Gun Sportsman’s Club in Lonedell, Missouri, Burt Reynolds, shot three of the rifles and I shot the other two. I gave him first pick, and he took the Mauser, Sauer, and Blaser, leaving me with the Model 70 and the Biesen custom. We encountered scope difficulties on the first group with the Mauser. After sorting that out, I shot the group with the Mauser M18 a day later.

The 75 rounds prepared for this test of velocity and accuracy included new, unfired Nosler brass and Federal Gold Medal 210M primers. Each powder charge was weighed, and all the powder came from the same new container of IMR-4064.

In broad terms, the results were very good although, not surprisingly, each rifle showed some idiosyncracies.

Only one, the custom rifle built by Al Biesen in the 1980s on an FN Deluxe action, recorded an average velocity of more than 3,000 fps (3,051 fps). The other four ranged from 2,947 to 2,997 fps. Strangely enough, the rifle with the lowest average velocity (the Mauser M18) had the smallest group while the Biesen had the largest. Equally strangely, the M18 is the least expensive rifle of the bunch, with a suggested retail of $695, while the Biesen probably cost $10,000 or more when it was made.

What does any of this prove? Not a thing, except perhaps that everyone should buy an M18 to keep as a spare.

Mauser M18:

1.29 inches, 2,947 fps

The most interesting single thing about this rifle is that, had I used the now-common method of averaging three, three-shot groups, it would have delivered accuracy of about .75 inch. As can be seen from the photo, its 10 shots also divided into two extremely nice five-shot groups. Bragging rights aside, the 10-shot group indicates great consistency and reliable accuracy, hot barrel or cold.

Sauer 404:

1.59 inches, 2,984 fps

Had I been betting on which rifle would give the best groups, I would have put my money on the Sauer, but given the Mauser’s sterling performance, runner-up ain’t bad. Again, it is a very consistent group, and without the two almost-flyers (top and bottom) it would have been fantastic.

Blaser R8:

1.82 inches, 2,997 fps

This Blaser has been delivering fine accuracy with many different .270 loads for a decade now, and this test was no exception. Again, the group size was stretched by a single flyer – but that is the harsh beauty of the 10-shot group. There is no place for a flyer to hide.

Winchester Model 70 Featherweight:

2.11 inches, 2,978 fps

This is a new-production Featherweight. It was the only rifle where there was a distinct shot-by-shot trend: The first half-dozen bullets went into the white bullseye, and the next four “painted” a tail on it to give it the shape of the Big Dipper. I was tempted to shoot it some more to see where the tail would lead, but refrained.

Biesen Custom:

2.22 inches, 3,051 fps

This Biesen has been my standard hunting rifle for the past two years and has proven itself extremely accurate with my usual hunting load. Although this IMR-4064 group is not bad, the rifle has shot much better in the past. Another odd thing is that, as far as I know, the barrels on the other four rifles were all hammer forged while the Biesen has cut rifling. It also has a very tight chamber, which helps account for the higher velocity.

Having fired 75 rounds in the course of this test, not one single case or primer showed any sign of even approaching maximum, much less excessive, pressure. If I intended to use this load for hunting with any of these rifles, I would probably start inching up the load, a quarter-grain at a time, watching for pressure signs while expecting the groups to tighten.

Jack O’Connor never stated exactly what he meant by fine accuracy with the rifles in which he tested this load but, since it was around 1950, I expect he was more than satisfied with a 1.5-inch, five-shot group. All of these rifles delivered that without breathing hard.

Another point to keep in mind, given the fact that all of these rifles have short barrels (21 or 22 inches) is that IMR-4064 should deliver higher velocities than H-4831 simply because it is a faster burning powder. Where H-4831 excels in a longer barrel, 4064 will generally do better in a shorter one.

One thing we should not lose sight of is that, even though this was a recognized, acceptable load in the 1950s and ’60s, recent manuals advise against exceeding 47.5 grains of IMR 4064. Since newer manuals are compiled with more scientifically exact test data, using new brass and pressure barrels, these warnings should not be ignored.

My belief is that lower brass capacity and resulting higher pressures played a big part in the results that O’Connor, Whelen and Waters wrote about a half century ago.

If nothing else, this is one more caution against blithely using ancient loading data without studying every component very carefully and – always – starting low and working up.