Wadcutters

Exploring Their Advantages

feature By: John Haviland | October, 18

Thumbing through my shooting records shows that my .357 and .44 Magnum revolvers have fired several hundred mild-

The solution to those wide velocity swings was the use of wadcutter bullets. These bullets seated flush – or nearly so – with the case mouth occupy more room in large cases like the .38 and .44 Specials and .357 and .44 Magnums to confine powder so the charge burns more uniformly. However, not all wadcutters are equally suitable. Commercial lead-swaged wadcutters are aggravating because they leave smears of lead in a revolver’s forcing cone and barrel when shot at velocities as low as 700 fps. Hollowbase wadcutters are a relic of the past, when the expanding skirt of the base was required to spread out to seal barrel bores that varied widely in diameter.

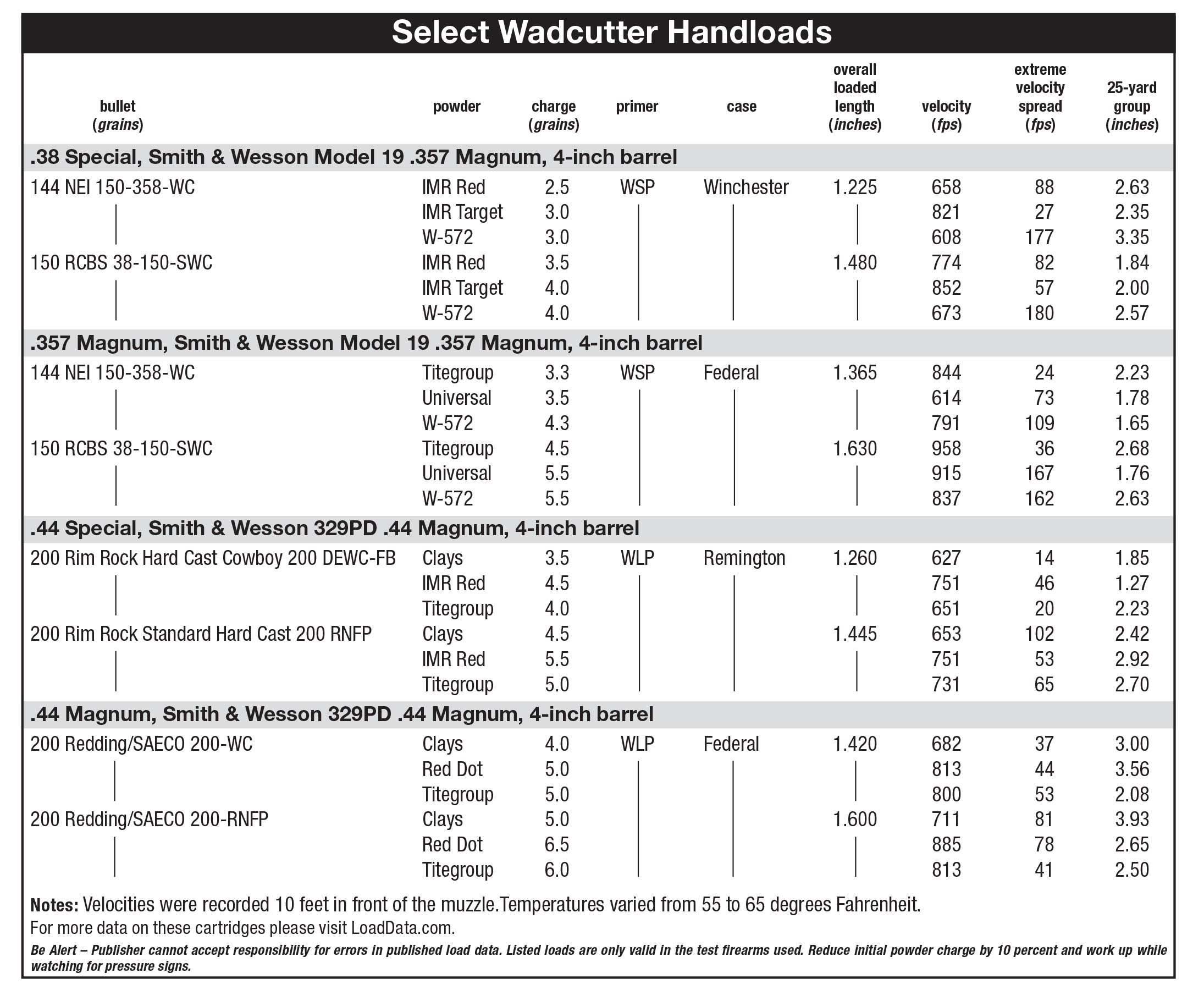

To determine if wadcutters actually reduce velocity spreads, I used two bullets I cast, and a commercially cast wadcutter. For comparison, elongated bullets of similar weight were also used, and they were loaded for velocities of 600 to 800 fps.

My casting furnace was full of Lyman No. 2 alloy that was used to cast bullets from the following moulds: RCBS 38-150-SWC,

The RCBS and NEI bullets were loaded in .38 Special and .357 Magnum cases, the two SAECO bullets in .44 Magnum cases and the two Rim Rock bullets in .44 Special brass.

The NEI wadcutter bullet has no crimping groove. The bullets were seated with their full diameter slightly below the mouths of .38 and .357 cases, and a slight roll crimp was applied, mostly to remove case mouth flare. Factory wadcutter loads usually have a cannelure around the outside of the case at the base of the bullet to keep them from being shoved deeper into the case during rough handling. But there was no need for that, as there was enough friction between the bullets and the inside of the cases that the bullets remained in place.

The bases of the wadcutters were positioned about .165 inch deeper than semiwadcutter bullets in .38 and .357 cases. The wadcutter bullets left about .20 inch of space between their bases and 3.0 grains of W-572 powder in .38 cases. The bases of SAECO .44-caliber wadcutters were seated about .195 inch deeper than RNFP bullets, and Rim Rock wadcutter bullets were seated .150 inch deeper than RNFP bullets.

For the most part, wadcutter bullets produced lower extreme velocity spreads than the semiwadcutter and RNFP bullets. In the .38 Special, wadcutters shot with IMR Target powder had an extreme velocity spread of 27 fps compared to twice that, at 57 fps, for semiwadcutter bullets. On the other hand, IMR Red and Winchester 572 gave rather wide spreads with both bullets.

The .357 Magnum fared better shooting wadcutters loaded with three powders. These loads turned in an extreme spread of only 24 fps with Titegroup powder, and Universal reduced velocity spread by more than half compared to the powder shot with semiwadcutter bullets. Wadcutters loaded over W-572 narrowed velocity spread by 53 fps compared to the semiwadcutters loaded over the same powder. Still, velocity spreads remained high using W-572 with both bullets.

Except for one inconsistency, the .44 Special produced fairly even velocities with Rim Rock 200-grain wadcutter and RNFP

Clays is my favorite powder for light-recoil loads for the .44 Magnum, and it continued to work well during this experiment. Clays delivered a velocity spread of 37 fps when paired with SAECO wadcutters – about half the velocity spread provided by SAECO RNFP bullets. Velocities with Red Dot varied nearly half as much when shooting wadcutters as compared to RNFP bullets. However, velocity spreads remained about the same for Titegroup with both bullets; 41 fps for the RNFP bullets and 53 fps for the wadcutters.

Reviewing all the numbers, several powders delivered uniform velocities with wadcutter bullets and acceptable velocity spreads with semiwadcutters and RNFP bullets. Titegroup, Clays, IMR Target and Red and Alliant Red Dot produced the narrowest velocity spreads.

Trail Boss is Reiber’s favorite powder for low-pressure loads. It ignites easily because its granules are porous and its rounded edges and hole in the middle provide lots of surface area for primer flame to reach.

Reiber has worked with wadcutters in the .38 Special and other relatively large handgun cases to develop load data for Hodgdon’s reloading manuals. He said hollowbase wadcutters loaded with fast-burning powders like Titegroup, Clays or Bullseye in the .38 Special provided superb results. “Cases were fairly well filled when a wadcutter was seated to produce uniform velocities, and the obturation of the

Wadcutter Uses

Long ago I carried a .22 handgun on hiking trips in the early fall to pot grouse along the trail. Blue grouse would fly off never to be found, unless a .22 bullet hit them in the spine or wing butts. I eventually started carrying a Ruger SP101 .32 H&R Magnum. My load consisted of 2.0 grains of Red Dot that fired Speer 98-grain hollowbase wadcutters at 742 fps from the Ruger’s 4-inch barrel. The bullets poked clean holes through grouse and killed them on the spot. There was no bloodshot meat, even when I stuttered on the trigger and a bullet hit the breast.

I have also shot grouse with the .38 Special loaded with wadcutters cast of wheel weights from NEI mould 150-358-WC. At a muzzle velocity of 650 fps the flatnose bullets poked a neat hole through grouse. Most were shot a step or two on either side of 15 yards, and none were shot past 25 yards. On one trail hike I had wadcutters loaded to a velocity of 900 fps. I shot one grouse through the wing butts and the bullet tore up the meat.

The remainder of those loads were shot at targets at 25 to 50 yards. It has been said that a wadcutter’s tin-can shape results in accuracy deterioration at distances past 50 yards. But wadcutter bullets provide uniform ballistics that result in plenty of accuracy within distances that the majority of handguns are shot.

The Reds

According to the manufacturer, Alliant Red Dot powder has been used with shotshells, handgun loads and reduced-velocity

IMR Red was introduced in 2017 to capture some of Red Dot’s market. IMR states Red is manufactured with environment-friendly technology and, in most cases, results in more energy from each grain of powder and with consistent bulk density from lot to lot. Reiber at Hodgdon (which owns IMR) said, “Red is easy to light and is clean burning.” Red has a burn rate similar to Alliant Bullseye and Red Dot, and it’s made in Canada.

I dispensed old Red Dot made in 2002, improved Red Dot and IMR Red through an RCBS Uniflow Powder Measure that remained on one setting. Old Red Dot dropped five charges that weighed 5.7 grains, two at 5.8 grains, two at 5.6 grains and one that weighed 5.5 grains. Improved Red Dot dropped six charges that weighed 5.5 grains, two at 5.4 grains and two at 5.7 grains. IMR Red provided five charges that weighed 5.5 grains, three weighing 5.3 grains and two that weighed 5.4 grains.

I weighed 5.5-grain charges of all three powders and loaded them with Rim Rock Standard Hard Cast 200-grain RNFP bullets in .44 Special cases and fired them from a Smith & Wesson Model 329PD .44 Magnum revolver to check ballistics.