M1 Garand Handloads

Powders That Work in the Old Battle Rifle

feature By: John Barsness | October, 18

Among Garand’s assignments was the development of a semiautomatic infantry rifle, and the resulting M1 was finally approved in 1936. Known informally as “the Garand,” the rifle was one of several American technological developments that definitely played a role in defeating the Axis powers. General George Patton famously called it “The greatest battle implement ever devised.”

Apparently, however, those who call the rifle “the Garand” usually mispronounce the name, saying “guh-ROND.” According to people who knew him, including General Julius Hatcher, Garand’s name actually rhymed with “errand,” with the accent on the first syllable. (However, Garand’s son John reportedly pronounced

The M1 Garand remained in service until 1959, and friend Tom Booker (a rifle loony of the first order) recently purchased one made at Springfield Armory in 1957. Tom is a retired engineer who is always busy with several personal engineering projects, including an elk-retrieval system for his pickup’s trailer hitch, so he was not adverse to loaning me his Garand to work up some handloads.

Along with the rifle, he provided a bag of Winchester 150-grain Power-Point bullets he had purchased off an Internet site for hunting handloads, and some 150-grain MK 4z military ammunition loaded by the U.S. military for British Commonwealth countries that continued to use the .30-06 long after the Lend-Lease program of World War II. (The “z” denotes the use of U.S. powder rather than British Cordite.)

During the M1’s initial development it was chambered in .276 Pedersen, a smaller, lower-pressure round with a .284-inch diameter bullet designed for use in semiautomatic rifles and light machine guns. In 1932 General Douglas MacArthur quashed the .276 because zillions of .30-06 service rounds already existed.

However, Tom is a confirmed handloader, so I started by doing considerable research on handloading for M1s, including the specific Garand sections in the Hornady and Sierra loading manuals. The basic rule is to use powders in the same general burn-rate range of IMR-4895, nothing much faster burning or, especially, much slower.

Over the years I had heard IMR-4895 was specifically developed by DuPont for the M1 rifle, but I also heard the M1 was designed around IMR-4895. This led to more research, and it turns out the M1 and IMR-4895 coevolved during the years leading up to World War II.

The original 1906 service load used a 150-grain flatbase spitzer at 2,700 fps – the same ammunition Theodore Roosevelt used

Various sources claim the M1 bullet weighed 172, 173 and 174 grains, a mystery explained by a list of .30-06 service loads in Hatcher’s Notebook, the reference work by General Julian Hatcher. The maximum bullet weight of M1 ammunition was a maximum of 174.5 grains but could be as much as 3 grains lighter. Similarly, the maximum weight of the “150-grain” bullet was 152 grains but could be as light as 149 grains.

For the Garand, the army decided to reproduce the original 150-grain ballistics, partly because it recoiled less and partly because the ammunition was somewhat lighter. The “basic load” carried by an infantryman was 88 rounds – an eight-round clip in the rifle, and 80 more in a bandolier. With IMR-4895, muzzle velocity was eventually raised to 2,800 fps.

However, unlike several other DuPont IMR powders developed during the 1930s, IMR-4895 was not available to handloaders until the late 1940s, when Bruce Hodgdon bought railroad cars full of war surplus IMR-4895 and sold it as H-4895. IMR-4895 available today is made in Canada and, while not exactly the original formula, is pretty close. Today’s H-4895 is a different powder, one of the Australian-made Extreme line offered by Hodgdon.

Due to its adaptation to the Garand, IMR-4895 was designed to burn most efficiently at around 50,000 psi, rather than the 60,000+ psi of many modern rifle powders, including the 20mm cannon powder Hodgdon sold as H-4831. I have long suspected the reason so many post-World War II gun writers stated accurate loads were usually found a few grains below listed maximum was the abundance of military surplus 4895. The powder was so versatile and affordable many handloaders used it for all their rifle loads. Consequently, many handloaders did find the finest accuracy with lower-than-maximum charges while many of today’s powders shoot best when loaded right up there.

I also decided to limit handloads to two bullets weighing 150 and 168 grains, approximating the bullet weights used during the development of the Garand. Not many bullet makers offer 172-grain .30-caliber bullets anymore, and while some published data includes heavier bullets, many Garand shooters advise against using anything heavier than 172 grains due to possible op-rod damage.

The brass used was new Federal, already primed with Federal 210s, purchased in a really good Internet deal a couple years ago. They seemed like a good choice partly because of their weight. Another standard piece of Garand handloading advice, and indeed for the .30-06 in general, is reducing powder charges a little in military brass because G.I. cases are usually significantly heavier than commercial cases. As a result, the same loads in military brass create more pressure, a real no-no in the Garand.

I had encountered this before with G.I. brass, and not just .30-06 but 7.62x51 NATO cases used in .308 and .358 Winchester rifles, but in this instance the Federal brass turned out to be heavier than Tom Booker’s 200-grain military cases, averaging 207 grains. Since the Federal brass also eliminated dealing with crimped-in military primers, I used it for all the handloads.

The first range test, however, was made with 1969 military ammunition, both to check point of impact with the M1’s sights and obtain some idea of accuracy and velocity. The only previous time I had fired a Garand was decades ago, when a friend brought one along for an informal plinking session. His rifle hit some empty cans at short range, and I mostly remember the recoil being pretty mild for a .30-06, no doubt due to both the Garand’s weight and gas operation.

I’ve used plenty of two-stage military triggers over the years, and the pull on Tom’s rifle was decent, the second stage averaging a pretty crisp 5.5 pounds. This may sound heavy to shooters used to modern bolt-action trigger pulls of 3 pounds or less, but is very controllable on a rifle weighing almost exactly 10 pounds with an eight-round ammunition clip.

I set up a target at 50 yards, partly because all the range sessions took place during a particularly windy Montana spring, and

wind drift at 50 yards was only a quarter as much at 100. But I also wanted to accustom my 60-something-year-old eyes to the sights and have found shooting at 50 yards puts less strain on them. Despite this age handicap, I still shoot irons pretty well, partly due to using them regularly. Some older shooters have trouble with iron sights when they try them again after decades of scope use, because they have forgotten the basic principles. But that is another story.After getting used to the trigger and sights, three-shot groups with the military surplus ammunition averaged 1.39 inches, the equivalent of a little under 3 inches at 100 yards – not bad for 50-year-old machine-gun ammunition and rugged sights not specifically designed for target work. Average muzzle velocity was just about 2,750 fps, a little less than 2,800 fps listed by Hatcher but certainly within the normal variation for both rifles and ammunition.

The rifle itself functioned perfectly – except for the very first round, a misfire. After waiting the standard two minutes with the rifle pointed downrange, I manually ejected the cartridge then pocketed it for break-down back in my loading room. It turned out to contain 53.2 grains of a powder that, not surprisingly, looked exactly like my supply of twenty-first-century IMR-4895. The bullet weighed 151.0 grains, within the specifications listed in Hatcher’s Notebook.

After three range sessions with handloads, Varget provided the finest accuracy with 150-grain bullets, and VV-N150 provided the best groups with 168s. Friend Kevin Thomas got wind of the VV-N150 news and sent an e-mail saying we needed to discuss VV-N150 in the Garand. Kevin has been in the shooting business a long time – we met more than a decade ago, when he was chief ballistician at Sierra Bullets – and these days he is in charge of technical services at Capstone, the U.S. importer of Vihtavuori powders.

Kevin contacted me because he’s a Garand shooter. While Vihtavuori’s loading data for VV-N150 makes it appear the powder is similar in burn rate to IMR-4895, Kevin said it is not: “We just completed some comparative testing with VV-N150 against 4350, and found them to be very, very close in terms of both performance and pressure curves. Close enough that I would be remiss in not pointing this out to anyone thinking of using the VV-N150 in a Garand. It’s just too slow to be comfortably recommended in a Garand with a good conscience. Op rods are not getting any cheaper these days.”

Instead he recommended either VV-N135 or VV-N140, and since he had recently sent me a batch of the latest Vihtavuori rifle powders – all temperature-resistant, with a decoppering agent – I decided to cease and desist with VV-N150 and switch to VV-N140. Luckily, I had only fired a few rounds, which had not damaged Tom’s rifle.

This brings up another point: The classic advice of using only powders in the IMR-4895 burn-rate range does not take into consideration changes in powders since the 1930s. Just because loading data for a certain powder makes it appear similar to IMR-4895, many newer powders burn more progressively, maintaining higher pressure farther down the bore – even all the way to the gas port on an M1 Garand.

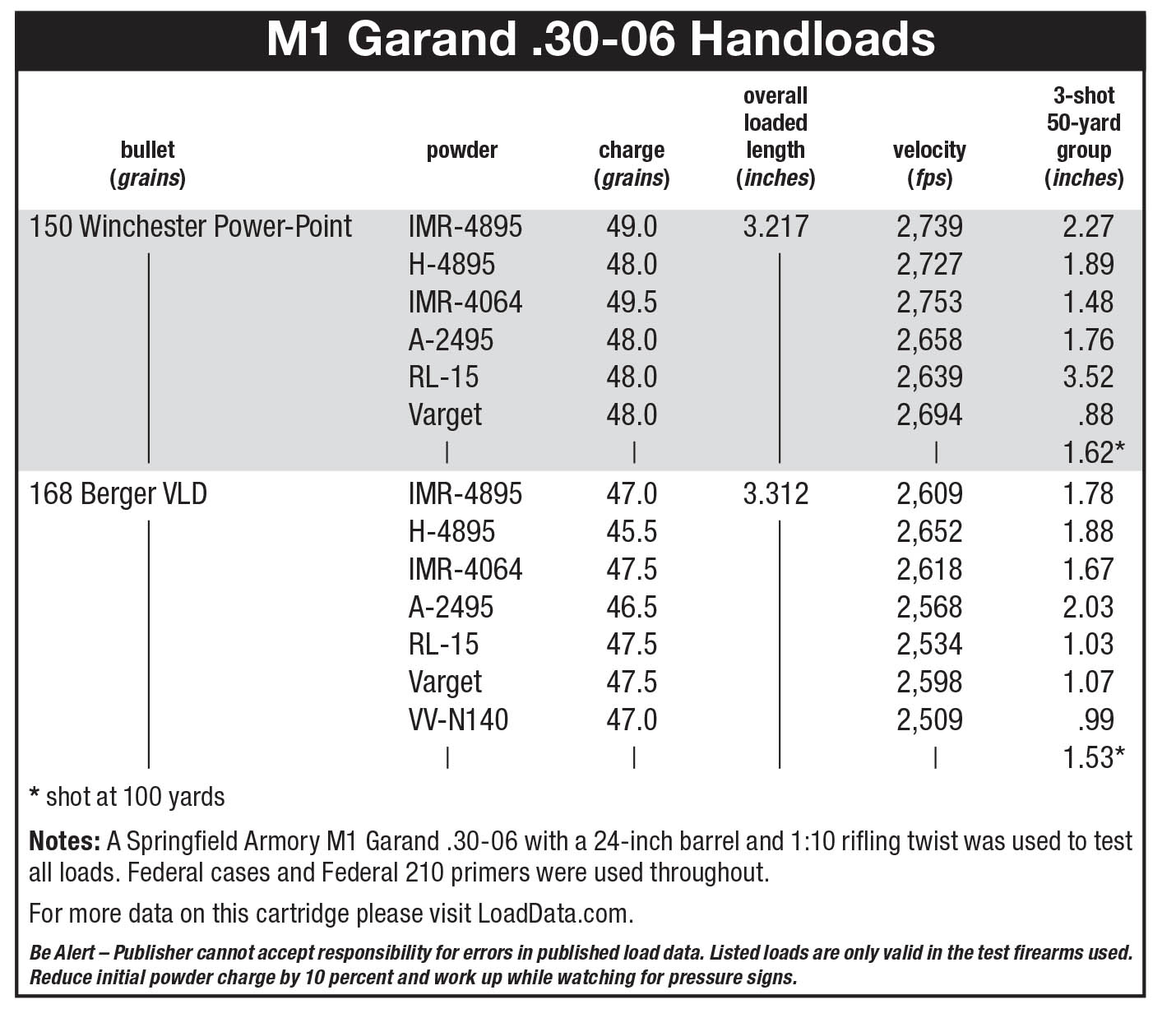

The handloads were worked up not only with just accuracy in mind, but also a certain velocity range to avoid overloading the operating rod. All the 150-grain loads ended up between about 2,650 and 2,750 fps, and the 168-grain loads ranged from 2,500 to 2,600 fps. Both the 4895s and Accurate 2495 resulted in okay, but not great, accuracy – and the 150-grain bullets did not work well with Alliant Reloder 15, though in many other rifles I have seen excellent results with all four powders. IMR-4064 worked pretty well, but the definite overall best powder with 150s was Varget.

With Berger 168-grain VLDs, VV-N140 won by a nose with RL-15 and Varget right behind. Results with the 168-grain bullets were more consistent overall, probably because of the quality of the Berger bullets.

After repeatedly testing all the handloads at 50 yards, I shot the most accurate loads with both bullets at 100 yards, confirming the results. This particular M1 Garand indicates some newer powders have the potential to improve the performance of the old battle rifle.