410 2½-inch Target Loads

Increasing Availability and Diversity While Cutting Costs

feature By: Aaron Carter | August, 24

“I believe they’re around $16.00 a box,” shared an employee of Bull Run Shooting Center, a nearby public shotgun range, after I inquired about the price of its Fiocchi 2½-inch 410 bore target loads. The worker was close as a quick scan at the register revealed the cost to be $15.25 per 25 shells, which, believe it or not, is actually a good deal. In fact, on its website, Federal Ammunition charges $21.99 for the same quantity of its Top Gun 410s and an extra dollar for its newer High Over All (HOA). Other firms charge more, while some split the difference. All are overpriced – if you can find them.

It’s unlikely that the 410 has ever experienced its current level of popularity and that’s part of the problem. Demand exceeds supply. The 410 was once chiefly used to hunt lesser upland species, as well as to introduce neophytes to shotgunning. Today, it is more frequently employed for registered, 410 specific “sub-gauge” events in tournaments – National Skeet Shooting Association (NSSA) and National Sporting Clays Association (NSCA) in particular. Also, it feeds large quantities of stacked-barrel handguns, and especially revolvers, such as the Taurus Judge/Judge Public Defender and Smith & Wesson Governor. That said, target loads aren’t a good choice for defense, but they’re satisfactory for building firearm familiarity and dispatching pests. Large stocks are required to meet the needs of these consumers alone. But wait, there’s more.

If you augment the aforementioned supply drains with the niche demand for modern, Tungsten Super Sport (TSS)-equipped, 3-inch 410 turkey loads, which have a cult-like following, then you understand why 410s are scarce. Plus, they’re produced in smaller quantities, which is a double whammy. Why?

The ubiquitous 12 gauge is, by far, the most popular gauge, followed by the 20 gauge. What’s more, according to Cartridges of the World, 13th Edition, “Except for the .22 rimfire, by almost any measure, the 12-gauge is the most popular sporting chambering ever offered.” Both 410 and 28 gauge are experiencing a resurgence, but neither approaches the esteem displayed for the 20 gauge, let alone its larger sibling. So, it only makes sense that ammunition manufacturers would concentrate their efforts on the best-selling products. “Four-ten” loads aren’t, so you must pay more to access them. Fortunately, you can reduce the economic pain through handloading.

The Fundamentals

Before delving into the specifics of handloading 2½-inch 410s, or any shotshells for that matter, the basic tenets of the task must be understood. First, when compared to metallic cartridges, handloading shotshells is straightforward – read and replicate. There is no “working-up” loads. Why? Signs of elevated pressures are evident only when a failure has already occurred – too late. Of the common shotgun gauges – and in the case of the 410 bore, the 2½-inch 410’s pressure is among the highest, boasting a Sporting Arms & Ammunition Manufacturers’ Institute (SAAMI) maximum average pressure (MAP) of 12,500 psi. Adhere to the information!

Shotshells utilize more components than metallic cartridges and they must be added sequentially. For instance, some 410 loads within this article call for an overshot card .410 (OS410), which is placed atop the shot immediately before crimping. All have a wad, and their individual design impacts fit and affects downrange performance.

Note that if a load is ill-fitting – despite adhering to the trustworthy data – it could be that the shot size selected is different than that used to develop the data (i.e. No. 7½ instead of No. 9, or vice versa). The increased (or smaller) diameter of the desired pellet can impact fit and thus the ability to create a solid, uniform crimp. In this case, an overshot card could be omitted without adversely affecting pressure. No other changes are permitted; instead, a different load would be necessary. As you’ll read, no gauge (or bore) is more finicky with regard to fit than is the minuscule, 2½-inch 410, and thus, it requires more forethought. Still, it’s worth the work.

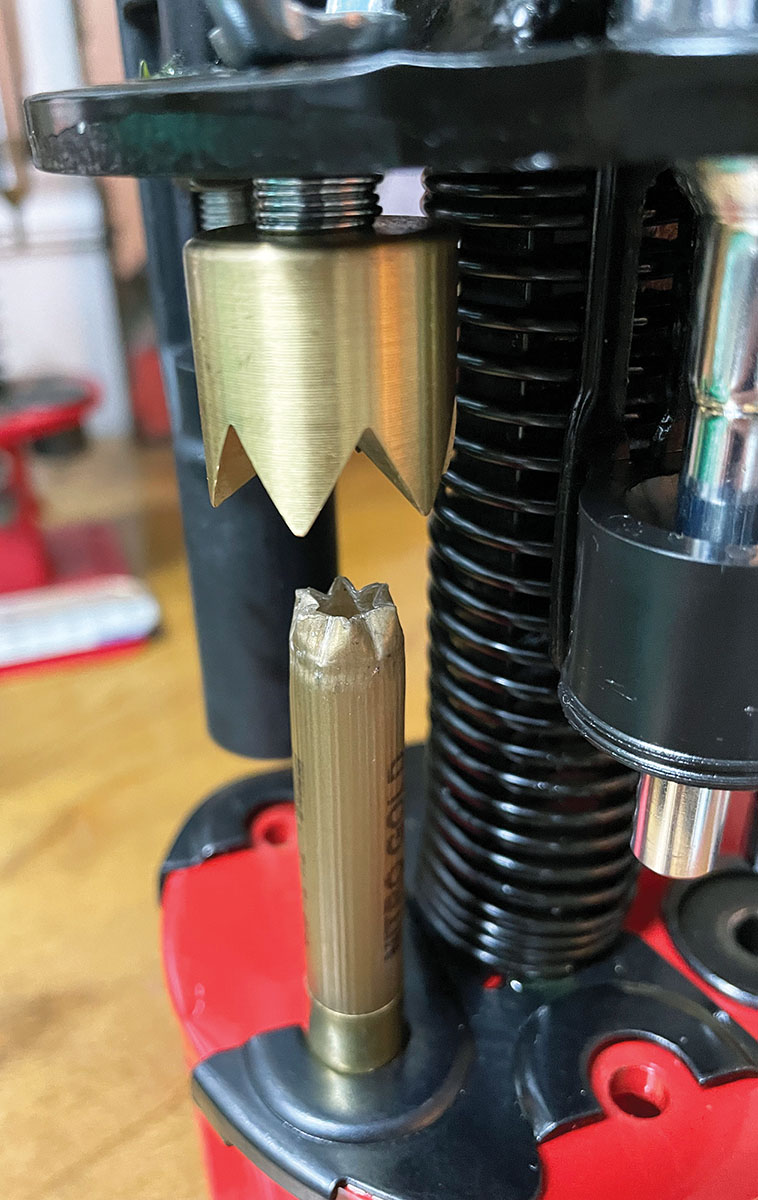

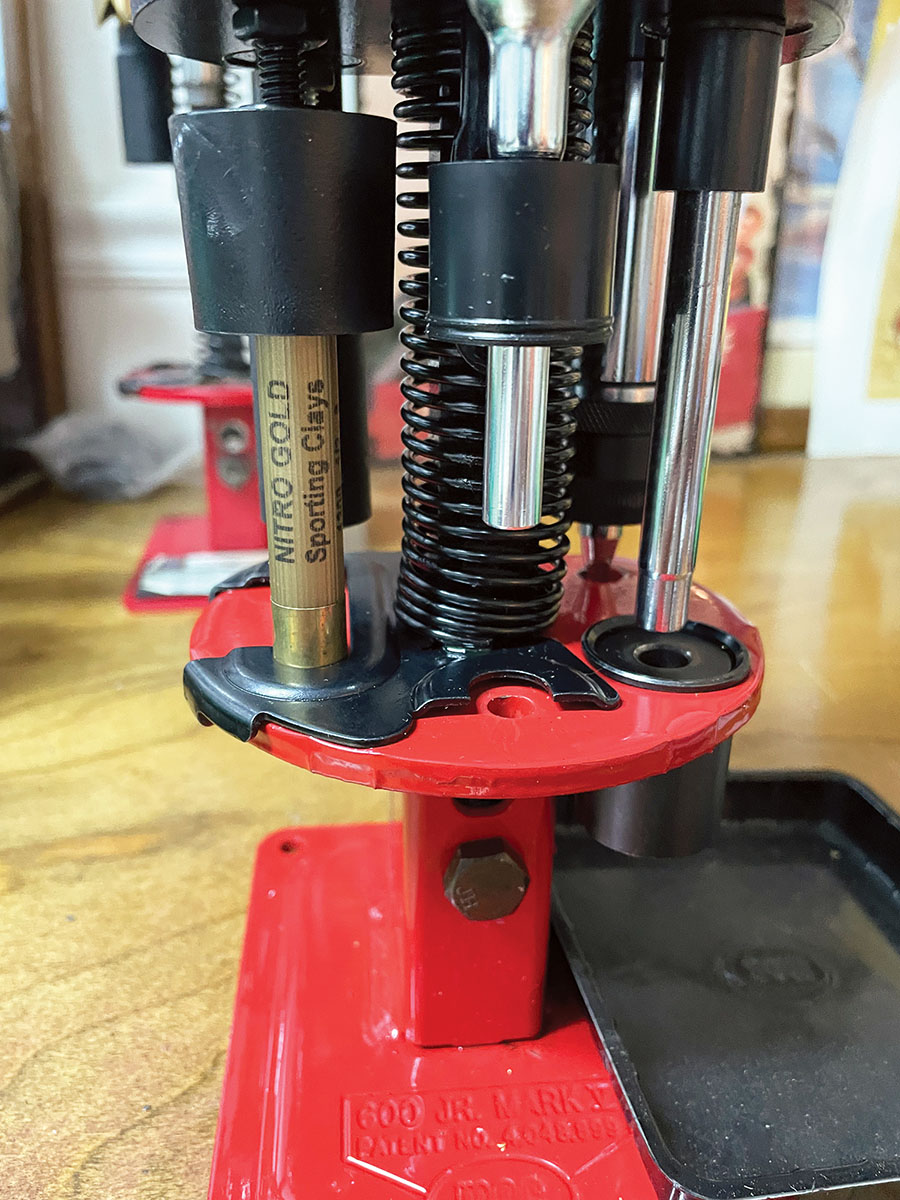

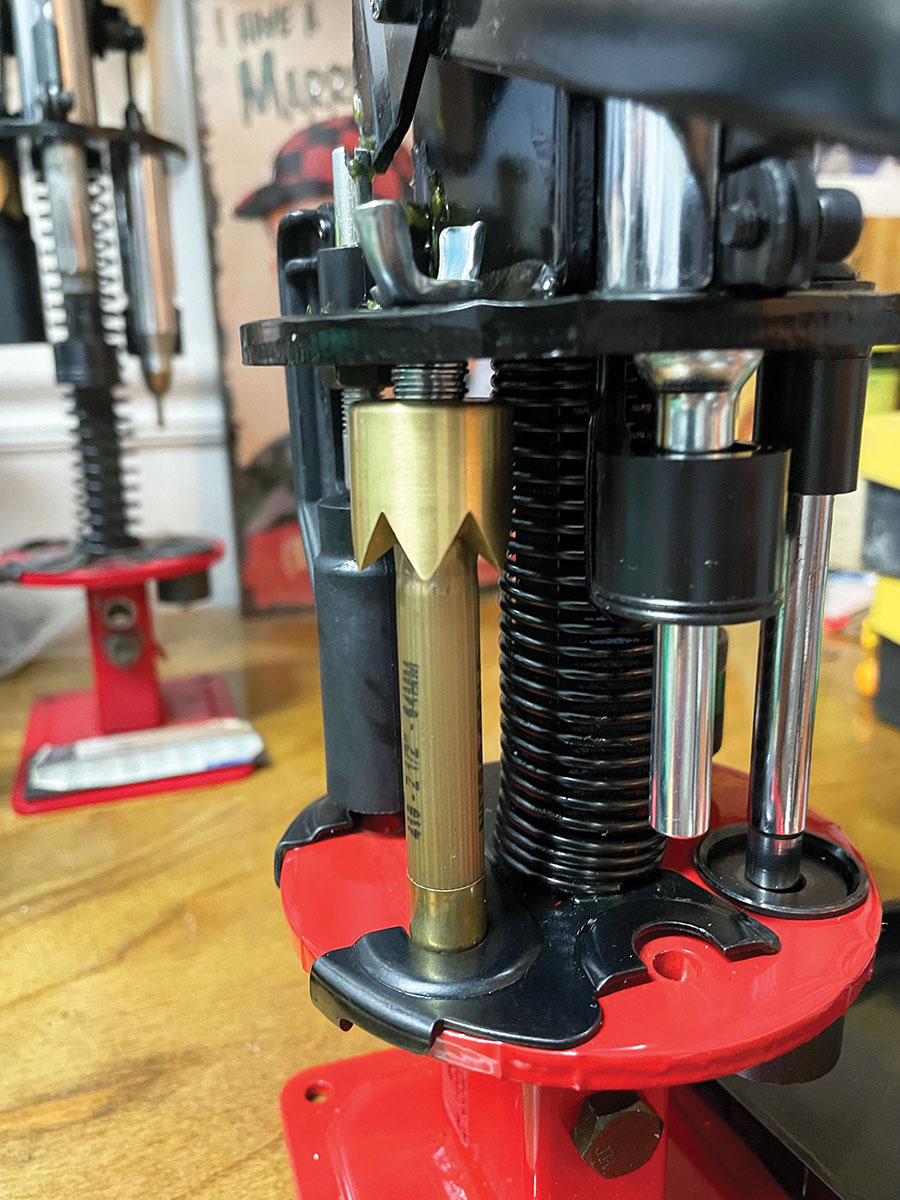

Presses, Hulls, Primers and Propellants

It’s unlikely that you’ll be firing 410s in high volume – even if competing in registered tournaments – so a single-stage press is a better investment than a progressive model. Like a lot of handloaders, I opt for an economical MEC 600 Jr Mark V, though the collect resizer of the upgraded MEC Sizemaster does a better job of resizing. As food for thought – both models are available in 2½-inch 410, which can be adjusted to accommodate 3-inch shells; however, the 3-inch model cannot be adjusted to accommodate 2½-inch shells. Although the plastic, Spindex Star Crimp that comes with the press works well with once-fired hulls, I still recommend replacing it with a Ballistic Products, Inc. (BPI) brass, six-point Super Crown Crimper, which gives the ability to create solid, deep crimps on new, primed hulls. That is what you’ll likely use most. Lastly, an Adjusta-Drop charge bar, also available from BPI, is a good investment.

If you can find them, new, primed 2½-inch hulls are around $20 per hundred. Given the cost of factory ammunition, as well as a 100-count package of shotshell primers, that’s not a bad price. Most likely you’ll locate either Cheddite or Fiocchi, though recertified domestic hulls have appeared from time to time. Foreign-made hulls work just fine, but don’t expect a long lifespan.

A key consideration when using imported hulls is their slightly larger primers. As an example, an American-made primer in a Cheddite or Fiocchi hull can result in a loose fit. Why does it matter? While cycling (post firing), the primer can fall out and lodge in the shotgun’s action, which is far from ideal. As such, you’ll need the proper primer for the hull.

Fortuitously, primed hulls, which don’t require hazardous shipping fees – eliminate this problem the first go-round, and when reloading, Cheddite and Fiocchi primers are consistently obtainable. As for domestic-made primers, they’re nigh impossible to find on a regular basis. Sadly, that negates much load data available on popular, trusted websites; the propellant manufacturers simply haven’t caught up to the absence of domestic primers for reloaders. Fortunately, data exists on the imported hulls – particularly in BPI’s renowned manuals.

Wads and Shot

Workable wads for the 2½-inch 410 are few in number, but you’ll find what you need. Although data widely exists for stalwarts, such as the Remington SP410, Federal 410SC, and Winchester WAA41 and WAA410 HS, the reality is you cannot find them. Fortunately, Claybuster has the three-petal CB5050-410HS, which is a direct replacement for those listed above and, thus uses the same data. It’s made to be used in Remington, Federal and Winchester hulls. Beyond this fantastic and utilitarian option, the best variety comes from BPI.

BPI’s dual-petal MG410 wad has a “longish” shot cup, yet not all pellets will be contained within it. The confined shot creates a dense core to the pattern, while the shot outside the shotcup will fill the fringe. Its optimal range is 20 to 45 yards. Its counterpart, the Stretch 410, also a dual-petal wad, is similar in design to the MG410 but has a longer shot cup (1.210 inches vs .730 inch). Therefore, tighter patterns can be expected. The optimal range is 25 to 45 yards, which is plenty of distance for the lowly 410.

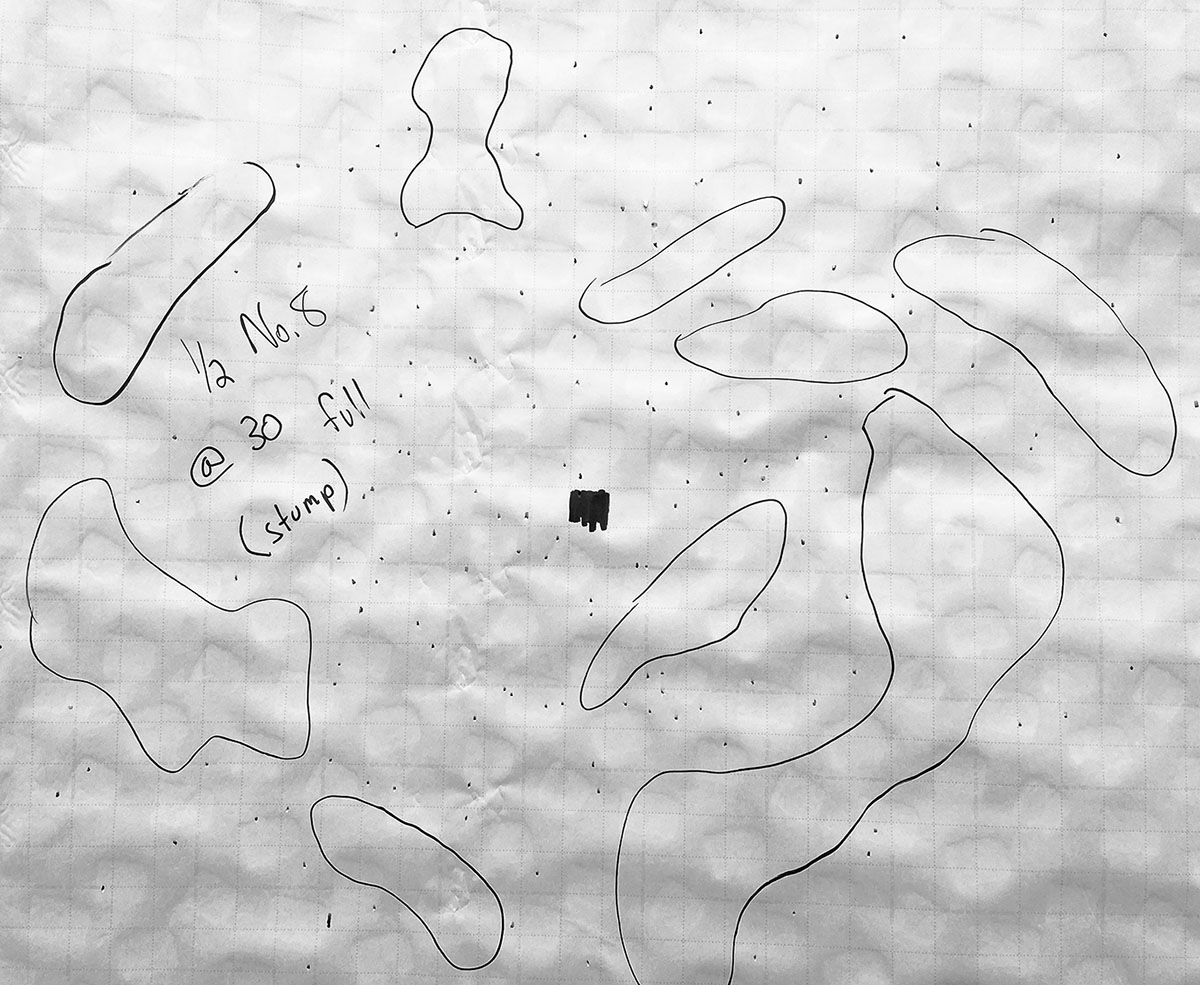

Whereas the MG410 is a utility wad, and Stretch 410 is better suited for distance work, they’re not the best options for close-in tasks. That’s the Stump 410’s forte. Measuring only .649 inch in length and absent a lengthy shotcup with petals, the minute cup captures only a small amount of shot. This leaves the bulk of the pellets to spread to the fringe of the pattern, essentially creating spread loads. For that reason, these wads are best used for 15- to 30-yard shots. Lastly, absent a lengthy shotcup, the material of which reduces bore diameter (and thus tightens patterns), the Stump’s patterns will reflect that of the actual bore – i.e. modified, full, etc.

Number eights are a perfect utility shot size. Measuring .090 inch in diameter, 205 are found in a ½ ounce payload. Patterns are noticeably fuller and reach is nearly as far as with No. 7½ shot. Only sub-gauge targets pushing the limits of the 20 and 28 gauge will give you fits when using No. 8s.

Candidly, I rely heavily on No. 8½ (.085 inch) shot. Relatively unknown to anyone who isn’t a competition shooter, the shot size is surprisingly capable and, with 245 pellets in a ½-ounce payload, makes it more difficult for a clay to avoid. I find it equally adept at destroying targets on the sporting clays course as it will in skeet. If you have some No. 8s and the majority No. 8½, you’re set for most encounters on the shotgun course.

Skeet shooters, in particular, like No. 9s (.080 inch) in the 410 due to the closeness of the targets and quantity of pellets. A ½-ounce payload contains 293 magnum lead-alloy pellets. But it doesn’t take long for a target to get outside of the No. 9’s effective range, so I opt for the larger No. 8½. Even when pushing 35 to 40 yards, you’ll still get target breaks with the latter.

Fine-Tuning 410 Loads

As mentioned elsewhere, no shotshell is fickler to handload than the 2½-inch 410. Due to its small internal volume, everything must be considered to create a proper load (with a quality, deep crimp). For instance, if No. 7½ shot is desired, then a load using a modest charge of spherical or extruded propellant and a wad with shorter petals is generally needed. But not always; only when loading will you discover the best combinations.

When evaluating loads for this article, the shotgun I used was a 24-inch barrel Mossberg Model 500 with a fixed full choke. The gun, which was purchased to introduce my eldest son to shotgunning, has won several NSCA-registered sub-gauge tournaments. Given its tight choke, it was also the perfect option to evaluate Stump “spreader” loads.

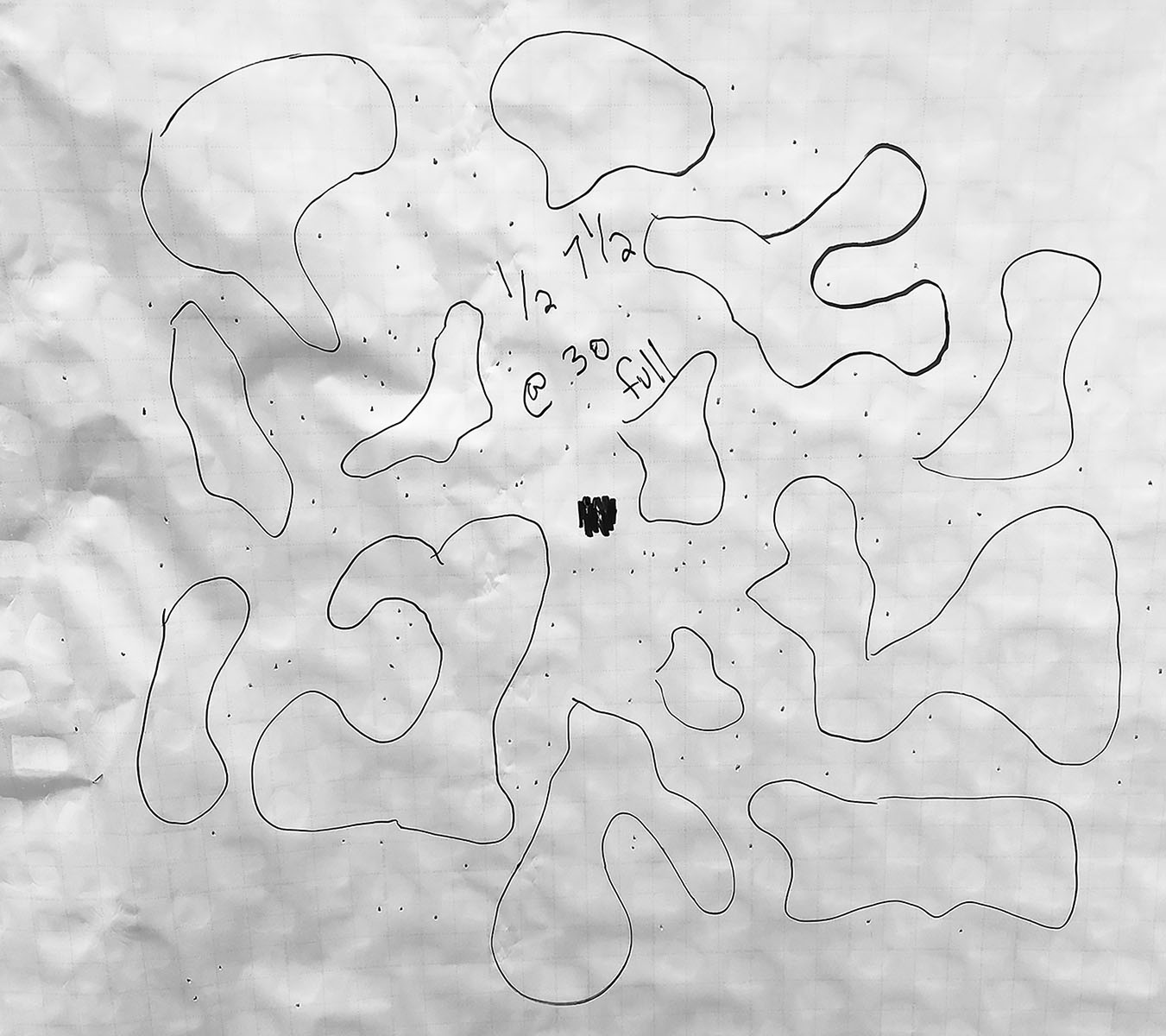

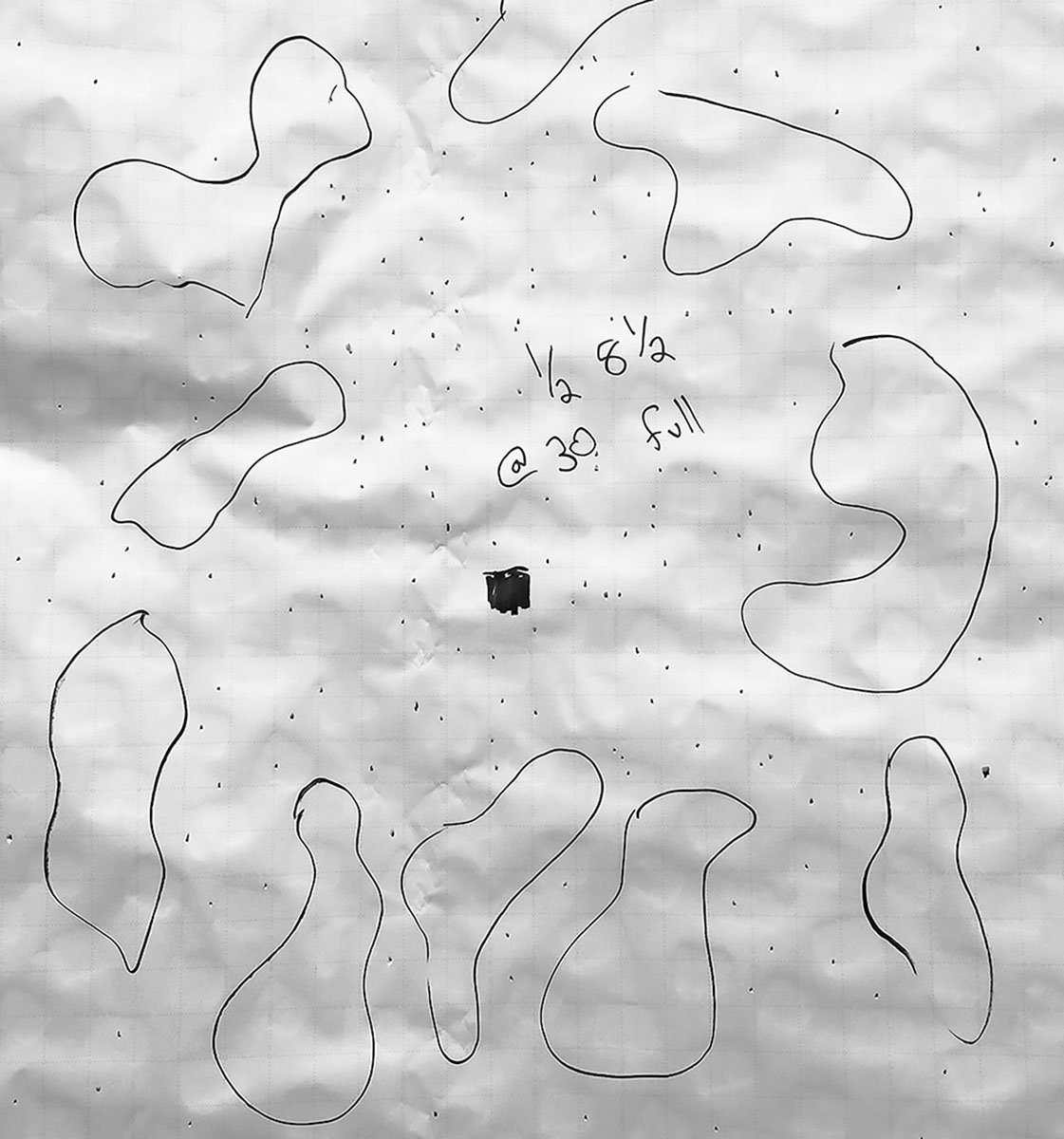

My other preferred components were Hodgdon Lil’Gun or Alliant 300-MP propellants and Winchester AAHS hulls. Ultimately, all of the tested loads functioned soundly and generated adequate patterns out to 30 yards. But, unsurprisingly, those with smaller shot sizes had, as a group, fewer pellet-less areas for a clay to slip through. Such is the trade-off and, as expected, the Stump wad created patterns with a denser core and wide fringe, making it ideal for skeet or close-in hunting of upland quarry.

Using prices of premium components, I found at BPI, I calculated that, even when new, primed hulls are used, I can load 25, 2½-inch 410 target loads for around $9.75 – about half (or less) of most factory loads. If you have once-fired hulls, you’ll be even more thrifty. Any time that you can use 410 handloads but don’t, you’re overpaying. Unlike 12-gauge target loads, where saving through handloading is minimal, such is not the case with 410s. So, invest in a 2½-inch 410 press, secure the necessary components and get started.

.jpg)