Bullets & Brass

Bullet Expansion Problems in 38 Special Short-Barrel Revolvers

column By: Brian Pearce | September, 24

Bullet Expansion Problems in 38 Special Short-Barrel Revolvers

Q: I always enjoy your technical articles and learn something from each one, even if I don’t handload for the cartridge of discussion.

My question today has to do with handloads for my 38 Special snub-nosed revolvers. I have several short-barreled revolvers (mostly Smith & Wesson J-Frame and Colt D frames) that I collect, shoot and carry for personal protection. I have been using 140-grain JHP bullets with 6 grains of Alliant Power Pistol powder, or 6.5 grains of Accurate No. 5. But in checking the velocity of these loads from a Colt Detective Special with a 2-inch barrel and a Smith & Wesson Model 38 with a 1.85-inch barrel, these loads were running around 750 feet per second (fps) and 720 fps respectively. In wet newsprint, they show zero expansion and penetration was dismal. Can you suggest a load that will reliably expand from these short-barreled guns? Or should I consider a different bullet for personal defense purposes?

C.Y., via Facebook

A: The problem that you describe is very common with short-barreled revolvers. While I can suggest loads that will increase the velocities of the various 140-grain JHP bullets that you mentioned, expansion will still remain poor, if at all. To achieve reliable expansion, it is suggested to choose an even lighter weight bullet and increase pressures to +P levels that are 20,000 pounds per square inch (psi). The Hornady 125-grain XTP is a great choice, as it will expand reliably at velocities as low as 800 fps, but higher velocity is always preferred. With that thought in mind, I would suggest using 7 grains of Power Pistol powder for 925 fps, or 7.3 grains of Hodgdon Longshot for around 940 fps. Another good option is to use the Speer 135-grain Gold Dot Short Barrel bullet, which can be pushed to 900 fps using 6.8 grains of Longshot powder, or 6.5 grains of Power Pistol for nearly the same velocity. Again, these loads are +P and should only be used in suitable revolvers.

Another option is to use the Rim Rock 148-grain DEWC bullet with 5 grains of Power Pistol powder for 870 fps. This is an outstanding load that does not need expansion to be effective, as its full-caliber meplat produces great shock effect and without expansion offers comparatively deep penetration.

How to Increase the Accuracy of My Handloads

I felt a little challenged and realized that there was room to improve my handloads. I was told that Nosler neck turns the cases of their factory loads, so I purchased an RCBS tool and prepared 50 Winchester cases and trimmed and chamfered them in the process. Cases were then loaded with the 180-grain Nosler Ballistic Tip bullet. But to my dismay, groups hovered around 1½ to 2 inches. I experimented with bullet seating depth and powder charge weights, but there were no real gains in accuracy. I checked the normal things, such as guard screws, scope bases and rings, but there was nothing loose. I thoroughly cleaned the bore, but nothing changed.

So what am I missing? What is Nosler’s secret formula? Why has my accuracy deteriorated? Any help that you can offer will be appreciated.

S.Y., via email

A: While it can be difficult to diagnose handloading problems from an email, I believe your problem is simple and easy to correct. First, Nosler does not turn the case necks of its factory loads. While neck turning cases often increases accuracy in custom and match rifles with tight chambers, in common production rifles with comparatively large (but not out of specification) chambers, this practice often decreases accuracy.

Incidentally, Nosler does not have any “secret formulas.” Rather, they prep cases by weight sorting, uniform the flash holes, sizing, trimming and chamfering. They use precision Nosler bullets with coaxial seating with minimal runout and are loaded in conjunction with powders that offer known accuracy qualities. If you take this same approach with your handloads, you should be able to fully duplicate or exceed the accuracy of Nosler factory ammunition.

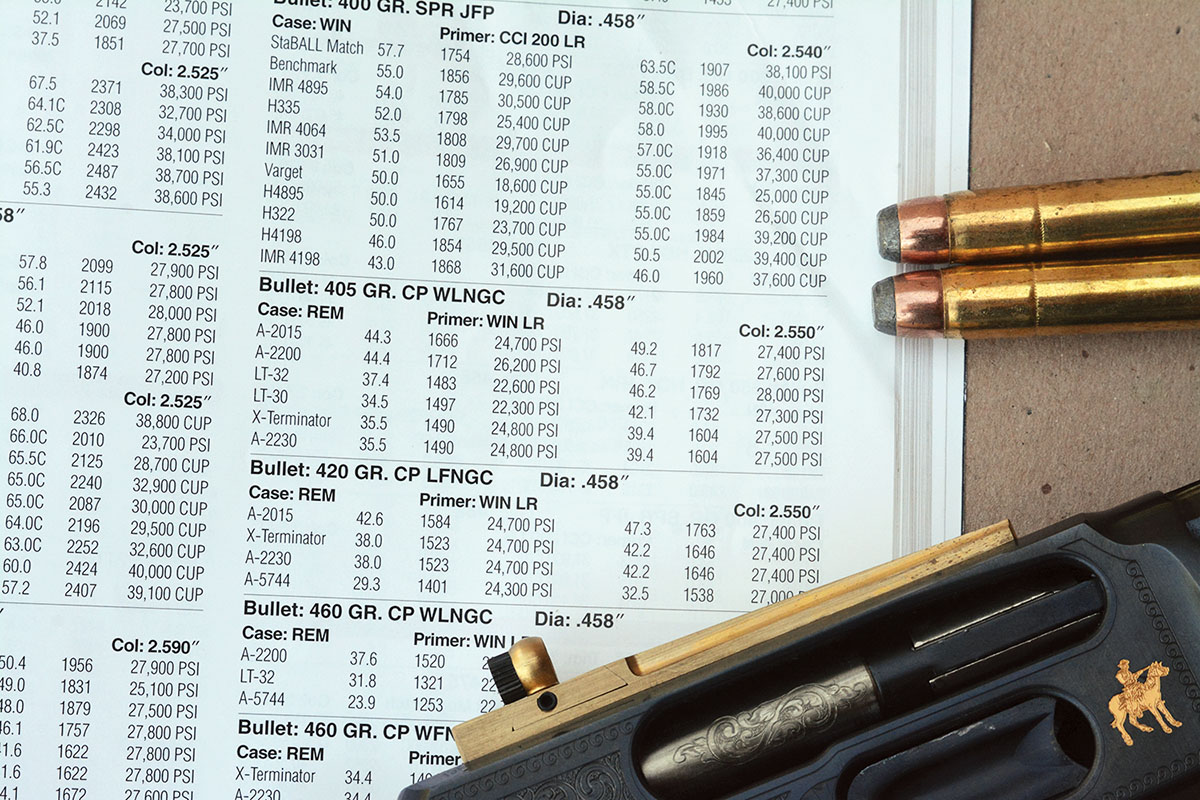

Safe Pressure Loads For a Ruger/Marlin 1895

I see some manuals, such as the Speer, limit loads for my rifle at 28,000 CUP. Others, such as the Hodgdon Annual Manual, list loads up to 40,000 CUP. But to make matters confusing, Hodgdon lists loads using both CUP and psi pressures and the maximum pressure figures range from around 23,000 psi to 40,000 CUP.

I was told that you are very knowledgeable on this subject and am seeking your advice. I would like to better understand the differences between psi and CUP measurements. Why is there such a discrepancy in recommended pressure levels for modern 45-70 lever actions from one manual to the next? And last, I would like to load the Speer 400-grain JSP bullet with a velocity of around 1,800 to 1,900 fps. Can you suggest a powder and charge weight? Thank you in advance for your help.

S.B., via Facebook

A: You just opened a can of worms, but today is not the time to get into the technical side of pressure testing methodologies and mechanics. To simplify matters, let’s first discuss CUP versus psi. Copper Units of Pressure, or CUP, is a much older method of checking pressures that utilizes a “copper crusher” cylinder that is ultimately crushed (in the chamber of the pressure barrel) and is less precise than the more modern psi. The psi is measured by a piezoelectric transducer system that is much more precise. The industry has been in the process of reshooting and updating data to piezoelectric or psi. But pressure testing is very time consuming and costly, so it takes time to update older data.

To better answer your questions, psi and CUP do not usually correspond or convert from one to another, although estimations can be made, the correlation is very complicated and varies from one cartridge to the next and many of the “estimations” have proven inaccurate. As an example, the 308 Winchester has an industry maximum average pressure (map) of 52,000 CUP, while the psi map is established at 62,000 psi. Regarding the 45-70, CUP and psi are not exact, but in this cartridge, they are generally very close. In other words, a load that generates 28,000 psi will generate very close to 28,000 CUP.

The Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) maximum average pressure for the 45-70 is currently 28,000 psi and 28,000 CUP. However, most ammunition manufacturers that are members of SAAMI hold pressures to 20,000 to 22,000 psi in deference to the U.S. Model 1873 Trapdoor rifles. Speer elected to develop handloading data that is within the SAAMI guidelines of 28,000 psi/CUP and listed it for both old and new Marlin Model 1895 and Winchester Model 1886 lever-action rifles (and others) that are known to be in good condition. In other words, they did not engineer this data for your modern Marlin Model 1895, which is much stronger than the old rifles that date back to 1895.

Regarding the Hodgdon data; the data presented in the 2024 annual manual is a compilation of data from several different ballisticians over many years. Each ballistician has their own ideas about what pressures should be limited to. Most of the data that you reference that is in psi was shot in the Western Powders lab (Accurate and Ramshot Powders) located in Miles City, Montana, which is a company that Hodgdon purchased a few years back.

Now, let’s get to the chase regarding the 45-70 data that you inquired about. I generally prefer to limit pressures at 40,000 psi/CUP for Marlin Model 1895 rifles produced since 1972. However, select data can reach up to 43,500 psi/CUP safely. Loaded to this pressure level and with the correct powders, the 45-70 provides remarkable performance and lively recoil. Using the Speer 400-grain JSP bullet, try 58 grains of Hodgdon Varget for slightly more than 1,800 fps, 56 grains of H-4895 for 1,850 fps, 53 grains of Accurate 2015 for 1,850 fps, or 52 grains of Hodgdon H-322 powder for 1,900 fps. The above loads were assembled in Starline cases and capped with a Winchester Large Rifle primer.