During the past 44 years, Kenny Jarrett’s shop has been about a rifle shot away from a wide place on a narrow road known as Jackson, South Carolina. During that time, he has built super-accurate rifles around about every high-performance cartridge you can think of as well as several you likely have never heard of. First came the 280 Ackley Improved, and while Jarrett will not say how many rifles he chambered for that one, I can tell you the number was many times more than just a few. The profits made on those rifles went a long way toward keeping Jarrett Rifles afloat.

The 300 Jarrett case was originally formed by using a Redding sizing die to neck down the 8mm Remington Magnum case. Today, 7mm STW brass is often easier to find and the same die with a tapered expander button available as an accessory from Redding is used to neck up that case. Either way, cases have to be fireformed in the 300 Jarrett chamber prior to charging with full-power loads. Shown here: (1) 8mm Magnum, (2) 7mm STW and (3) 300 Jarrett.

The 7mm Shooting Times Westerner, or 7mm STW for short, sprang from the bushes in 1977. I still have the first rifle built and it has been with me on many successful hunts for a variety of game in various parts of the world. Its crowning achievement thus far is an interior Alaskan grizzly much larger than the average size of coastal brown bears taken each year. My handload pushed a then-new Federal 160-grain Trophy Bonded Tip to 3,150 feet per second (fps) and the bruin was dead before I could chamber a follow-up round. Lesser known is the fact that the rifle is a switch-barrel rig with its second barrel chambered for the 8mm Remington Magnum case necked up for .416-inch bullets. We will never know how many 7mm STW rifles were sold by Jarrett but here is one indication. When arriving for a visit one sunny summer day in 1980, Jarrett greeted me with “I want to show you a new swimming pool the 7mm STW built.”

Then one day it dawned on Jarrett that the cartridges making the biggest contributions to the success of his business had been designed by other people. You can never go wrong with a good .30-caliber cartridge, so around 1985 he took a hard look at the 358 Shooting Times Alaskan, for which he had chambered a few rifles and came up with the 300 Jarrett. Redding was the first to make reloading die sets for it.

Backing up several decades, while Roy Weatherby was developing his great 300 Magnum during the 1940s, IMR-4350 was the slowest-burning propellant available on the commercial market. Extremely slow-burn powders such as Alliant Reloder 23, Hodgdon’s H-1000 and Vihtavuori N570 were decades away from being introduced. So in order to reach the velocities sought with IMR-4350 at chamber pressures considered by Weatherby to be acceptable, he gave the bullet a long-running start prior to engaging the rifling by free-boring the chamber. While a great idea in those days, such a rifle can be pickier about the bullets it will shoot accurately compared to a rifle with more standard chamber dimensions.

The 300 Jarrett is shown here with some of its older and newer competition. In a pinch, 300 Weatherby Magnum and 300 H&H Magnum factory ammunition can be fired in a rifle chambered for the 300 Jarrett. Shown are: (1) 300 Jarrett, (2) 300 Weatherby Magnum, (3) 300 H&H Magnum, (4) 300 Winchester Magnum, (5) 300 PRC and (6) 30 Nosler.

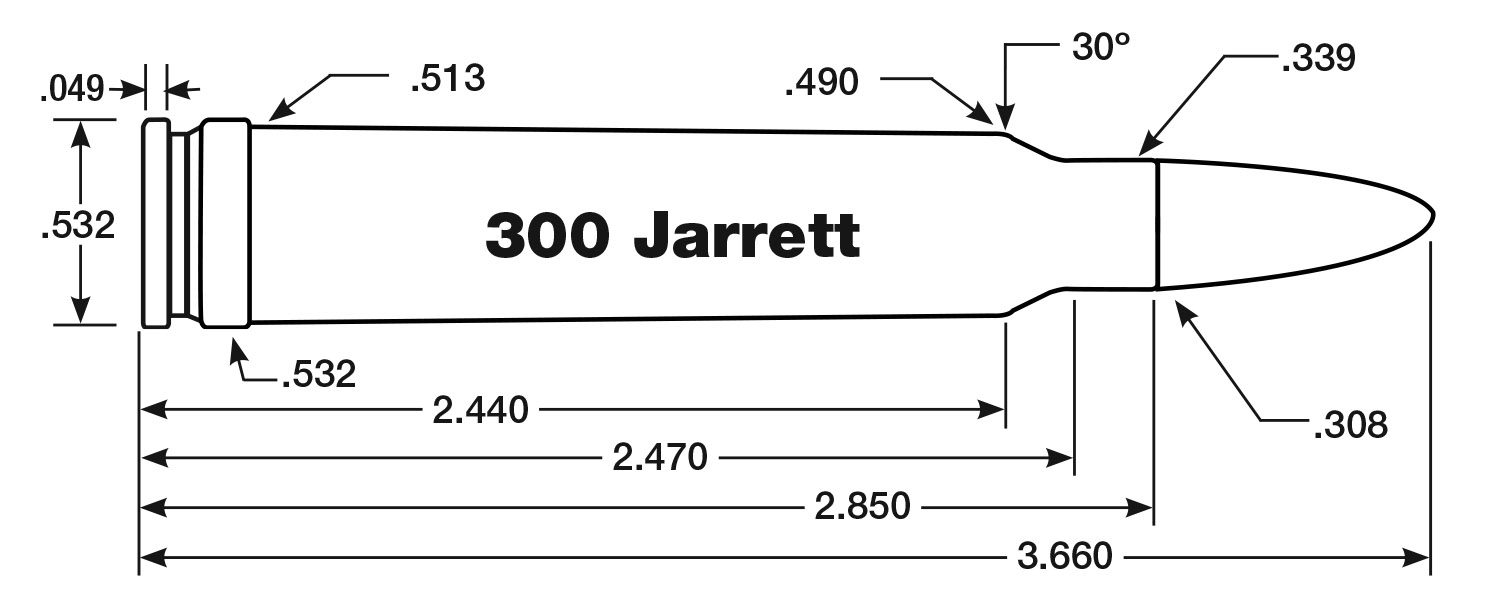

Jarrett’s goal was to develop a cartridge capable of reaching 300 Weatherby Magnum velocities in a standard chamber without free-boring while delivering 300 Winchester Magnum accuracy. The 300 Jarrett case was formed by using a Redding full-length sizing die to neck down Remington 8mm Magnum brass. After receiving a Federal 215 primer, a case was charged with 79 grains of H-1000 powder, topped off with a 180-grain bullet and fired in the 300 Jarrett chamber. Out popped a case with minimum body taper and a shoulder angle of 30 degrees.

A few years back, Jarrett switched to 300 Jarrett cases with the proper headstamp made exclusively for him by Norma. When holding the Jarrett and Weatherby cartridges side-by-side, the former appears to have a slight capacity advantage but looks are deceiving. Hodgdon’s BL-C(2) has about the same gravimetric density as water, so after weighing the two cases, I filled them to the brim with that powder and weighed them again. Average gross capacities were 106.5 grains for the 300 Jarrett case and 108.5 grains for the Weatherby case. Sectioning the two revealed a thinner web and wall in the Weatherby case.

It might be of interest to add that when available in the needed diameters and weights, Jarrett has long used Nosler Ballistic Tip “blems” when forming cases and testing his rifles for accuracy. Prior to being boxed up for shipment, each and every bullet made by Nosler is closely inspected and the slightest surface blemish will cause a bullet to be rejected. Most are so small they would go unnoticed to the untrained eye and I know first-hand there is no difference between the accuracy of Nosler bullets with those blemishes and those of pristine appearance. See the comparison by Jeremiah Polacek in the Handloader No. 349 (April – May 2024) issue. I am quick to point out that ammunition loaded by Jarrett Rifles for customers has always had pristine Nosler bullets.

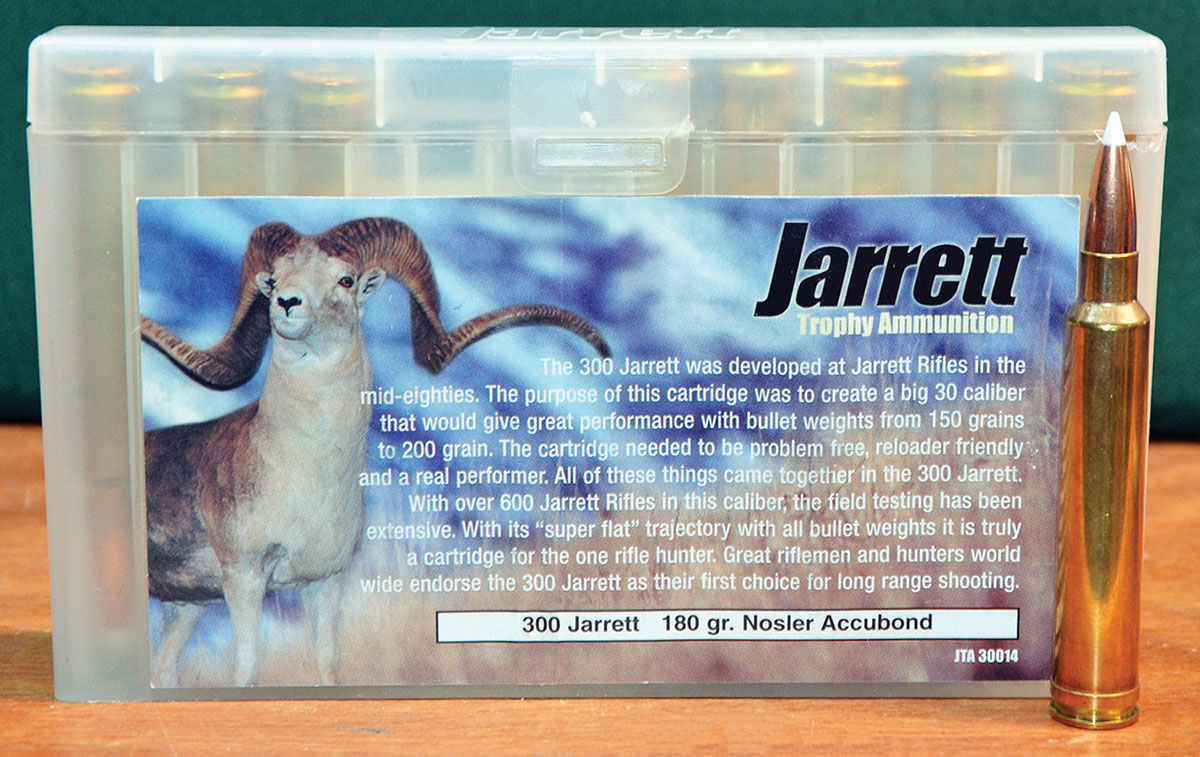

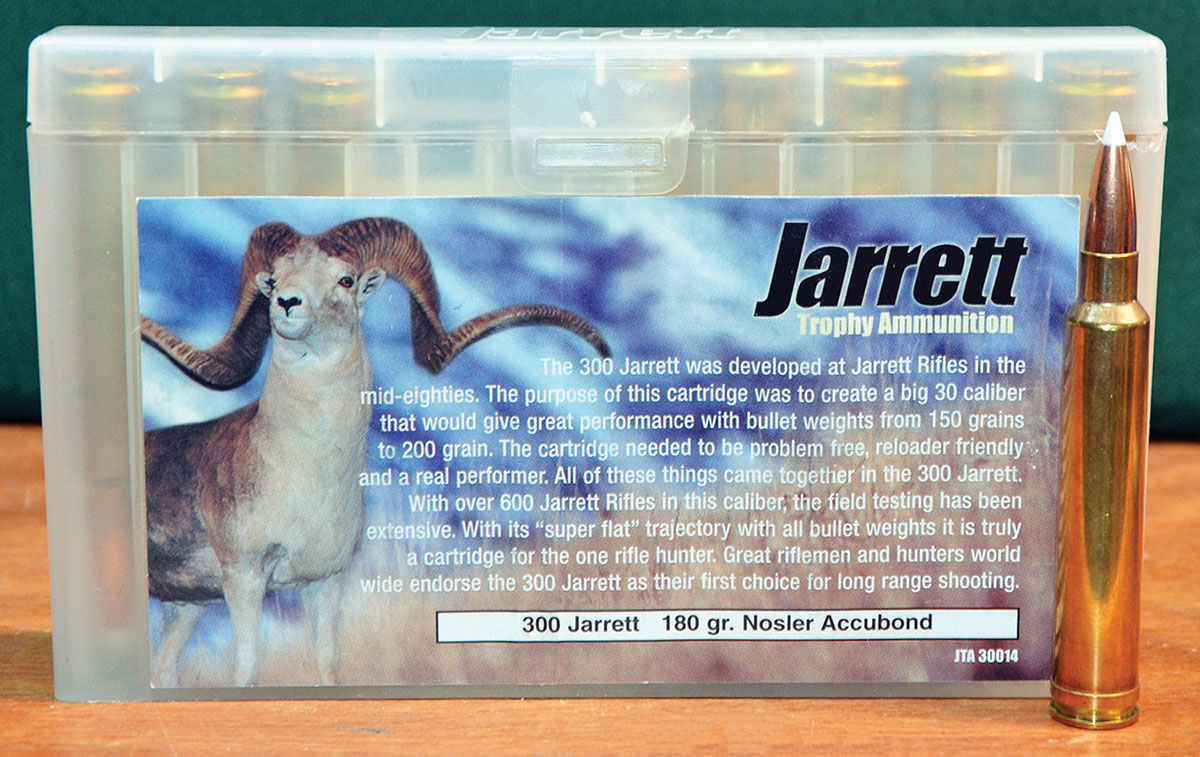

A rifle built at Jarrett Rifles will not be shipped to a customer until it is averaging less than a half-inch for three shots at 100 yards. In addition to receiving the load data, the new owner of the rifle has the option of purchasing ammunition loaded in the Jarrett shop. Cases with the proper headstamp are made exclusively for Jarrett by Norma.

In one of his promotional write-ups, Jarrett stated that when pushed to a velocity range of 3,350 to 3,450 fps by several powders, the Nosler 165-grain Ballistic Tip, which he recommended for use on deer-size game, never failed to average half-minute-of-angle for three shots. The 180-grain AccuBond was equally accurate and better suited for use on larger game. The Nosler 180-grain and 200-grain Partition bullets were not as accurate but both were accurate enough at the distances most hunters take game. Jarrett was also quite fond of Swift bullets weighing 180 and 200 grains. Claimed maximum velocities from a 24-inch barrel for bullets weighing 150, 165, 180 and 200 grains were 3,600 fps, 3,450 fps, 3,250 fps and 3,050 fps respectively. He was quick to point out that when the 300 Jarrett was loaded with the Nosler 200-grain Partition at 3,000 fps, it shot considerably flatter than the 338 Winchester Magnum (250-grain bullet at 2,700 fps) and delivered more energy to an elk standing on the far side of a wide canyon.

This 100-yard group was fired by Layne in 1974 with a Jarrett Ridge Walker rifle in 300 Jarrett. His handload consisted of Federal 215 primers, cases formed from Remington 8mm Magnum brass, 83.5 grains of Reloder 25 and the Nosler 180-grain AccuBond seated in the case for .020 inch of jump.

Jarrett spent a lot of time deciding on chamber dimensions. What he came up with would best be described as the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) minimum if the 300 Jarrett was a SAAMI cartridge, but it is not. He also experimented with leade angle of the chamber but that information is locked safely away with the recipe for Coca-Cola. His standard rifling twist of 1:12 can be a bit slow for some of the extremely long bullets we have today, so quicker twist rates are now available.

I will conclude with my favorite 300 Jarrett story. While visiting him shortly before his official introduction of the cartridge, I closely examined a loaded round and then casually mentioned that in a pinch, 300 Weatherby Magnum ammunition could be fired in a rifle chambered for it. By the look on his face, I knew he seriously doubted my statement. Jarrett’s shop is not far from Augusta, Georgia, which is where a small beach/shack-style restaurant called Rhinehart’s that serves the world’s best fresh-off-the-boat seafood with its breaded, deep-fried shrimp at the very top of my list. Jarrett and I both enjoyed eating there so a bet concerning cartridge interchangeability was on. His home and shop are out in the boonies and his 100-yard range is behind his shop. Even though it was late at night, I rounded up a couple of 300 Weatherby Magnum cartridges, strolled out the back door and fired both in the Jarrett rifle. The free meal at Rhinehart’s was the best I had eaten there.

.jpg)