Propellant Profiles

Shooters World Multi Purpose Black

column By: Randy Bimson | September, 24

As the name Multi Purpose Black implies, Shooters World’s objective is to offer the black-powder shooters a substitute powder that: is domestically made and widely available at both the local gun shop and big box stores alike; is a single propellant that covers the entire spectrum from cowboy action handgun, shotshell, and carbine cartridges, Schuetzen, buffalo rifle and English black-powder express cartridges; and of course, the traditional muzzleloading rifle, shotgun, pistol and cap and ball revolver. It leaves little residue, is non-corrosive and easy and quick to clean up. A tall order to ask of one propellant.

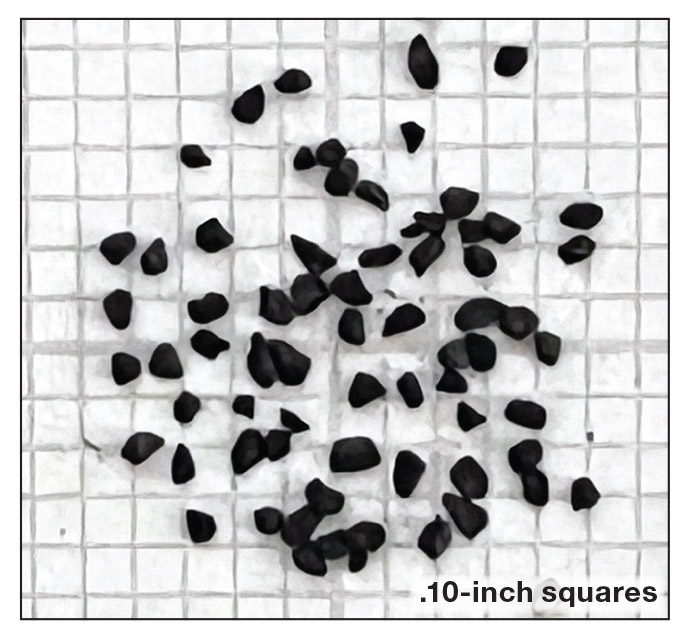

First, let’s delve into the technical aspects of Multi Purpose Black. Physically, the granules are coal-like in appearance, black in color and unlike traditional smokeless powders that come in identifiable shapes e.g. cylinder or sticks, flakes, spheres or flattened spheres, Multi Purpose Black is very irregular in shape with angular edges and not directly measurable (at least not easily) and is a proprietary design detail. What I can tell you is if we were to grade this in traditional black powder terminology, I would say the granules span the spectrum from FFFG to FFG in size. I will circle back around and talk about this a little more when I get into reviewing the range performance of Muti Purpose Black.

Now to my range report. The firearms I used for range testing were a Ruger No. 1, a 28-inch heavy-barrel Lyman Centennial model chambered in 45-70 Government and fitted with a period-type Lyman Centennial 4-power scope, as a representative cartridge gun. My Ruger Old Army cap-and-ball revolver represented the muzzleloading field. I believed that the large capacity 45-70 rifle cartridge and the comparatively small powder capacity of the Ruger Old Army would give a good demonstration of just how multi-purpose Multi Purpose Black truly is.

I first shot Multi Purpose Black in the Ruger Old Army, with some trepidation. If I am going to have an ignition problem with a black-powder gun it is the Ruger although using Track of the Wolf’s Old Army specific hex-head 411 stainless steel nipples has eliminated the problem with any practical powder/percussion cap combination.

Charges of Multi Purpose Black are comparable to traditional black powder by volumetric measure so I employed a Ted Cash Manufacturing revolver powder measure to throw the Old Army powder charges by volume. Hornady .457-diameter balls, RMC Ox-Yoke pre-lubed over powder wads and CCI No. 11 percussion caps were used exclusively with the Old Army. Ignition was 100 percent over 10 five-shot strings. Time constraints prevented setting up my Oehler 35P chronograph, so I cannot report on comparative velocities and standard deviations. However, I can attest that the identical charge, 35 grains by volume, of Multi Purpose Black almost equals my all-time best accuracy load of 35 grains of Triple Seven FFG, 1.264 inch center-to-center versus 1.130 inch center-to-center of a five-shot group at 20 yards fired from a Ransom International Multi Cal Steady Rest. Impressive.

Multi Purpose Black is advertised, like traditional smokeless powders, as safe to use in conventional rotary cylinder, slide-type, or electronic powder dispensers commonly found on the handloader’s bench. Loading for the Ruger No. 1, I used my RCBS Uniflow powder dispenser and verified the charge weights on a Redding Model No. 2 powder and bullet scale. New Starline 45-70 Government cases were processed using a Lyman sizing die, a Lyman “M”-type expander die, and the new Lyman Pro stainless steel micrometer seating die. The 405-grain bullet was cast using the Lyman No. 457193 mould, sized to .458-inch using a Lyman sizer die and top punch, lubed with Lyman Black Powder Gold bullet lube all set up in an RCBS Lube-A-Matic 2 lube sizer. Winchester WLR primers touched off the powder charge.

Shooters World’s loading data lists a charge, by weight, of 54 grains in combination with a 405-grain bullet. No other detail is given on the bullet but one would “assume” it is of the Lyman No. 457193-type.

The following guidelines are given for load density/bullet seating depth: “General loading instructions are to fill the case with loose powder just to the point where the base of the bullet will very slightly compress the powder, about 1⁄16”, when it is seated. NO FURTHER COMPRESSION is recommended or advisable and will result in increased pressures and erratic velocities! It is important that no air space or gap be left when the bullet is seated, and the use of fillers is not recommended for general cartridge shooting but is often required and acceptable for achieving the lower velocities desired in Cowboy Action Shooting. The filler should be composed of an acceptable material as recommended by the Single Action Shooting Society.”

Interestingly, a weighed charge of 54 grains filled the Starline cases to within about 1⁄8 inch of the mouth of the case. To seat the No. 457193 into the case to the crimp groove requires the bullet to be seated .575-inch deep. In accordance with the manufacturer’s guidelines, to be able to seat the bullet to the crimp groove, I had to drop the weighed charge to 49 grains. Feeding the powder charges into the cartridge case via a 24- or 36-inch drop tube may eliminate that problem.

As mentioned, no chronograph data was available on this range day so I cannot comment on how the drop in charge weight affected velocity. What I can attest to is the accuracy of the load. Three five-shot groups shot off the bench at 100 yards returned a respectable average of 1.450 inches.

Here are some personal insights into Multi Purpose Black. We have been taught that the uniformity of the burn rate of typical smokeless propellants is primarily a factor of the physical form. That being said, the irregular shapes and size of the individual granules would lead one to think that the burn rate of Multi Purpose Black would vary considerably and velocity variation from shot to shot would be high. The very respectable accuracy attained with the two test firearms certainly does not bear that out. Cleaning guns is like slopping pigs, it is a means to an end and not much fun for most folks. Also, powder fouling can build up in the barrel, in and around action parts and degrade accuracy and mechanical function. After shooting both test guns, my first impression of Multi Purpose Black was “Wow, this powder sure is clean!” After 50 shots, the Old Army cylinder rotated as freely as the first shot out of a clean revolver. Back in Handloader No. 333 (August – September 2021) in my “Propellant Profiles” column, I tested Hodgdon’s Triple Seven FFFG and noted little fouling, a light gray film, was left on the exterior of Old Army compared to the ample black crud left by Pyrodex P. Multi Purpose Black left even less fouling than Triple Seven, inside and out of the Old Army. Powder fouling does build up in the first couple of inches of the barrel forward of the chamber. This fouling did not impair the accuracy of either the Old Army revolver or the Ruger No. 1 rifle. After firing 15 rounds through the No. 1, without swabbing the barrel, the fouling in the bullet seat/throat area did not make any noticeable difference seating a loaded cartridge into the chamber.

To tempt fate, I left the barrels of both test guns and the cylinder of the Old Army uncleaned for five weeks. Not the least sign of corrosion – thank goodness. Cleaning was almost fun! The fouling remained soft, and a single patch soaked with “Aquoil,” an emulsified solution the color of Bailey’s Irish Cream, only better smelling, is made of one part Parker-Hale Young’s 303 Solvent mixed with three parts water, removed all but the faintest trace of the fouling in both barrels. A second patch so soaked came out virtually clean and a third dry patch left the bore of both barrels sparkling like a diamond. A cotton swab soaked with the Aquoil solution makes cleaning the Old Army cylinder charge holes a breeze. The Old Army’s cylinder nipples unscrewed without a hint of resistance.

Shooters World Multi Purpose Black is packaged in 1-pound canisters and if like me, you shoot a variety of muzzleloading and black-powder cartridge guns, I highly recommend you give it try. Carrying a flammable solid classification, you should be able to find it in most well-stocked local guns shops and big-box sporting goods stores. If not, tell your dealer you read about it in Handloader and suggest they start stocking it.

.jpg)

In closing… Since retiring from SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute) in 2020, I have had the privilege of writing the “Propellant Profiles” column of nearly two dozen issues of the Handloader Ammunition Reloading Journal. My family has allowed me 55 years to pursue my singular passion of working in the firearms and ammunition manufacturing industry. Now, I find that it is my turn to repay them by making them the focus of my time and attention. Handloader No. 352 (October – November 2024) will be the last “Propellant Profiles” column to bear my byline. I hope that as readers of Handloader, you have enjoyed these columns and, occasionally, found a nugget of wisdom or technical information that you have found useful in your pursuit of the handloading hobby. However, it will not be the last you see of me in Handloader or Rifle magazines. Our Editor, Jeremiah Polacek, is allowing me to write feature articles on subject matters relating to firearms and ammunition that are of interest to me and, I hope, you as well.

So long for now,

Randy Bimson