Handloading for 30-06 Rifles

Developing One Load for Multiple Rifles

feature By: Charles Sandoz | June, 25

Developing the specifications and protocol for an accurate handload for a collection of seven bolt-action rifles in 30-06 Springfield-caliber proved to be an interesting project. When the handloader is faced with the challenge of developing a recipe and specifications for multiple rifles in a collection or for a group of friends’ rifles, a few additional planning and measurement steps are required compared to reloading for only one rifle.

The major challenge is choosing the optimum bullet and cartridge length(s) for all the rifles when the objective is a large batch of reloaded cartridges to be used by multiple rifles.

If this is your first reloading project for 30-06 rifles, then the first part of the project is to consult your library of reloading manuals to find a list of popular powder choices for the 30-06 Springfield. For this project, Ramshot Hunter powder was chosen because of its suitability for the 30-06 and precise metering capability with popular powder measures. The author uses a powder measure exclusively to dispense the desired amount of powder and, whenever possible, chooses a powder with a grain size and geometry that meters precisely.

Consulting SAAMI 30-06 Springfield cartridge specification indicates an overall cartridge length (measured from cartridge base to bullet tip) of 2.940 to 3.340 inches and a length range of .40 inch. A quick check of other popular calibers yielded a much smaller range in cartridge length specifications: .140 inch for 7 mm Remington Magnum, .275 inch for 270 Winchester and .32 inch for 308 Winchester. Check the SAAMI specification for the caliber you are reloading to indicate the potential variation between rifles you may encounter for your reloads. Manufacturers of 30-06 rifles typically chamber their rifles to accommodate this extensive range of possible cartridge lengths. A variation in chamber throat dimensions and bullet nose contour creates a large range of compatible cartridge lengths for the test rifles in this article. Within this sizeable acceptable cartridge length window, the handloader should choose the most optimum cartridge dimensions for their collection of rifles.

For most rifles and cartridges, target group size will vary with bullet jump distance, and frequently, any given rifle will produce the smallest groups at some narrow range in jump distance. When reloading for multiple rifles in a historic caliber such as 30-06 Springfield, the potential for a large range in chamber throat size exists, and measuring each rifle’s cartridge length when the bullet touches the lands is a very important factor in bullet selection and determining the reloaded cartridge length specification.

A good place to begin the reloading protocol development is to measure commercial ammunition that performed well with your rifles and look up the manufacturer’s velocity specifications.

Bullet Selection

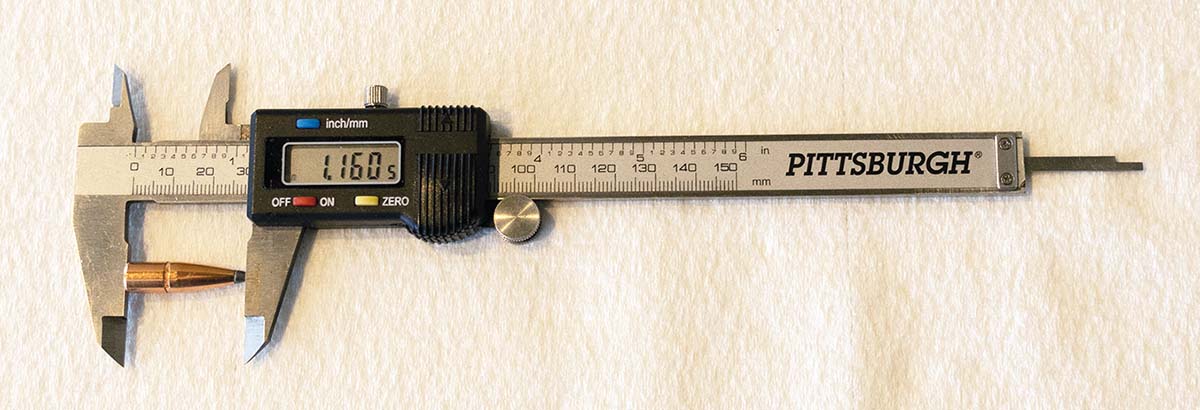

Thanks to the generosity of the bullet manufacturers listed in Table II, the author evaluated 33 unique .308-inch bullets for the 30-06 reloading project. Bullet dimensions were measured with a Hornady Lock-N-Load bullet comparator and a caliper. BOL is the measurement from the bullet base to the tip, and BOAL is the bullet length measured from the base of the bullet to the ogive. The dimensional difference among all the listed bullets is significant and directly affects the desired cartridge length required to achieve a specific bullet jump distance for minimum group size.

Based on the bullet dimensions in Table II, it is evident that many of them are very different in size as the bullet’s overall length ranges from .933 to 1.742 inches. With this vast range in bullet length, we need to choose the best bullet weight, design and shape for our application and rifles. The charts include the cartridge length when the bullet is in contact with the rifling for each of our test rifles. They illustrate the significant challenge faced whenever we try to reload for multiple rifles.

The chart that compares the range in cartridge length by rifle and bullet identifies the bullets with the smallest range in cartridge length for all seven rifles. The bullet(s) with the smallest range in cartridge length minimize the number of cartridge length specifications required to achieve the bullet jump distance that yields the smallest group size.

.jpg)

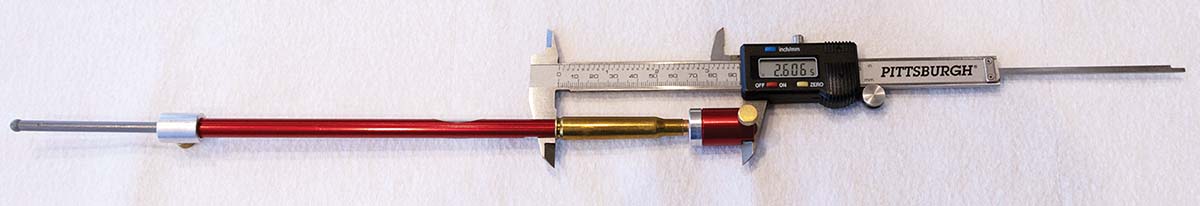

Cartridge dimensions were measured with a Hornady Lock-N-Load Straight OAL Gauge, Bullet Comparatorand a caliper. The most precise measurement of cartridge length (OAL) when the bullet is touching the rifling is obtained when using the Bullet Comparator.

Four of the eleven 150-grain bullets (Winchester, Sierra, Nosler AccuBond and Ballistic Tip) in Chart No. 2 have approximately a .15-inch range in cartridge length for the seven test rifles. These four bullets provide the minimum number of cartridge length specifications required for the smallest target group size with all seven rifles.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Three of the eight 165-grain bullets (Hornady 3040, Hornady 3045 and Berger VLD) in Chart No. 4 have approximately a .13-inch range in cartridge length for the seven test rifles.

Four of the five bullets (Nosler, Norma, Sierra and Speer) in Chart No. 6 have approximately a .15-inch range in cartridge length for the seven test rifles.

Three of the eight bullets (Barnes 30349, Nosler and Barnes 308175X) in Chart No. 8 have approximately a .15-inch range in cartridge length for the seven test rifles.

For the intended hunting and target applications, a 165- to 168-grain bullet has the ideal weight. The overall cartridge length varied from 3.22 to 3.52 inches using the bullets listed in Chart No. 4 touching the lands for the test rifles. A range of .3 inches is huge when the goal is to have a cartridge with a bullet jump of .045 inches for all test rifles. Based on the data in Chart No. 3 and Chart No. 4, the best bullet choices are the Hornady 165-grain InterLock 3040 and 3045 bullets. Although the Berger 168-grain VLD Hunting bullet has a small COL range, for the test rifles to achieve a bullet jump of only .045 Inches requires an overall cartridge length that exceeds the maximum SAAMI specification of 3.340 inches and may not fit in four of the test rifle magazines.

The Reloading Protocol

After securing an adequate supply of the chosen bullets, powder, primers and brass, the reloading project is ready to begin.

The first step is to remove all the primers from the used brass. The author prefers to use the RCBS Universal Decapping Die to remove primers because this die will handle most calibers and only requires the appropriate shell holder. Another advantage to using this die instead of the resizing die for depriming the case is that it keeps the dirty brass away from the sizing die to avoid scratching its polished, resizing surfaces.

The next step is to clean the brass after the primers have been removed using the Lyman Model 2500 Turbo Sonic Cleaner with Turbo Sonic Concentrate – mixed according to the manufacturer’s instructions. After the brass is clean and dry, the next step is to resize it. The handloader has a choice of resizing dies from several major manufacturers, and they consist of two basic styles in terms of how they resize the case neck. Standard dies resize the case neck to a smaller than the desired caliber and then pull an expander ball through the neck to obtain the proper neck tension to secure the bullet. This type of die is a little simpler to use because it accommodates brass with a variety of neck-wall thicknesses but does not provide a cartridge with as small an amount of bullet runout as resizing dies that externally resize the neck. Benchrest and long-range shooters have used dies for years that are available with neck bushings to optimize neck tension, minimize work hardening of the brass and provide cartridges with very small bullet run out for optimum accuracy.

The author began using the RCBS MatchMaster reloading dies for all of his handloading projects a few years ago. These dies provide a convenient and precise micrometer head on the bullet seating die for setting the precise overall cartridge length. The resizing die, with its neck bushing system, provides a reloaded cartridge with significantly less bullet runout, which is a great way to reduce target group size.

One of the challenges when using a resizing die that will externally resize the neck is choosing the correct neck bushing for the brass on hand. The brass used in this project had a neck wall thickness ranging from .012- to .016-inch when measured with a caliper and required the use of neck bushings of .331- to .336-inch to obtain the appropriate neck tension to secure the bullet in the case neck.

One option is to measure neck thickness with a caliper to determine bushing size, but it has a significant limitation – for many cases, the neck thickness is not uniform around the case mouth. A better option is to measure the case with a neck tension gauge after resizing, such as the one offered by Forster Products.

The data in the following pie charts were obtained using the Forster Neck Tension Gage (NTG) after the brass was resized with the RCBS MatchMaster resizing die using the bushing size indicated. After resizing, the brass was trimmed to 2.484 inches and deburred. Each batch of brass (quantities varied from 48 to 100 cases) was sorted by neck size and the percent of each neck size in each lot of brass was calculated. The data illustrates the variation in case neck ID by brass brand and use history. The charts make the compelling point of how important the use of the Forster NTG is in order to achieve reloads with adequate and consistent neck tension when using resizing dies with neck bushings. The Forester NTG is easy to use, consisting of four OD sizes in .001-inch steps. Sort the brass that does not have a gauge measurement of step numbers 2 to 3 and resize it with an appropriate bushing that yields a case that has a Forester NTG measurement in the step numbers 2 to 3 range. For any .308-inch OD bullet, step numbers 2 to 3 are equivalent to .305 to .306 inches.

Another reloading equipment variable that affects the bullet runout of the reloaded cartridge is how well the bullet fits the bullet seating plug in the bullet seating die. Table III lists how well the standard seating plug and a custom plug supplied by RCBS for Speer 165-grain BTSP bullets fit each listed bullet. It is a good idea that, if your chosen bullet does not fit the seating plug, to send a few of them to your seating die manufacturer and have them supply a seating plug that fits the bullet you plan to use.

The RCBS Trim Pro-2 Power Case Trimmer kit was used to precisely trim case length, and the RCBS Brass Boss was used to deburr and chamfer the cases. The Brass Boss provides up to six rotating and two stationary tools that can be used to clean the case neck, primer pocket and case mouth easily and conveniently.

We are now ready to prime the cases with Winchester Large Rifle primers and develop the best powder charge to meet our muzzle velocity and velocity standard deviation objectives. Ramshot Hunter was chosen for this project because it is recommended in many reloading manuals for the 30-06 Springfield and is easy to meter with a powder measure. Consulting the powder manufacturers reloading information and commercial ammunition manufacturers for typical muzzle velocity for 165-grain bullets (Table I), the powder charges and muzzle velocity measurements listed in Table IV were evaluated. The velocity measurements were obtained with a 22-inch barrel and the chronograph 12 feet from the muzzle. The charge of 58.3 grains was chosen because it yielded an acceptable bullet velocity and the smallest velocity standard deviation. In the author’s experience, a velocity SD smaller than 9 fps is rarely required and difficult to achieve.

The author has had a good experience with a bullet jump approximating .045 inch for the type of bullet used in this article. As a compromise, batches of reloads with three different cartridge lengths were prepared for the seven test rifles. Cartridges with an OAL of 2.724 inches were prepared for the 1903 Springfield, a batch with an OAL of 2.64 inches was prepared for the Mark X Rifle A & B, and a batch with OAL of 2.607 inches for Mark X Rifle C, U.S. M1917 Rifle A & B and Winchester M70.

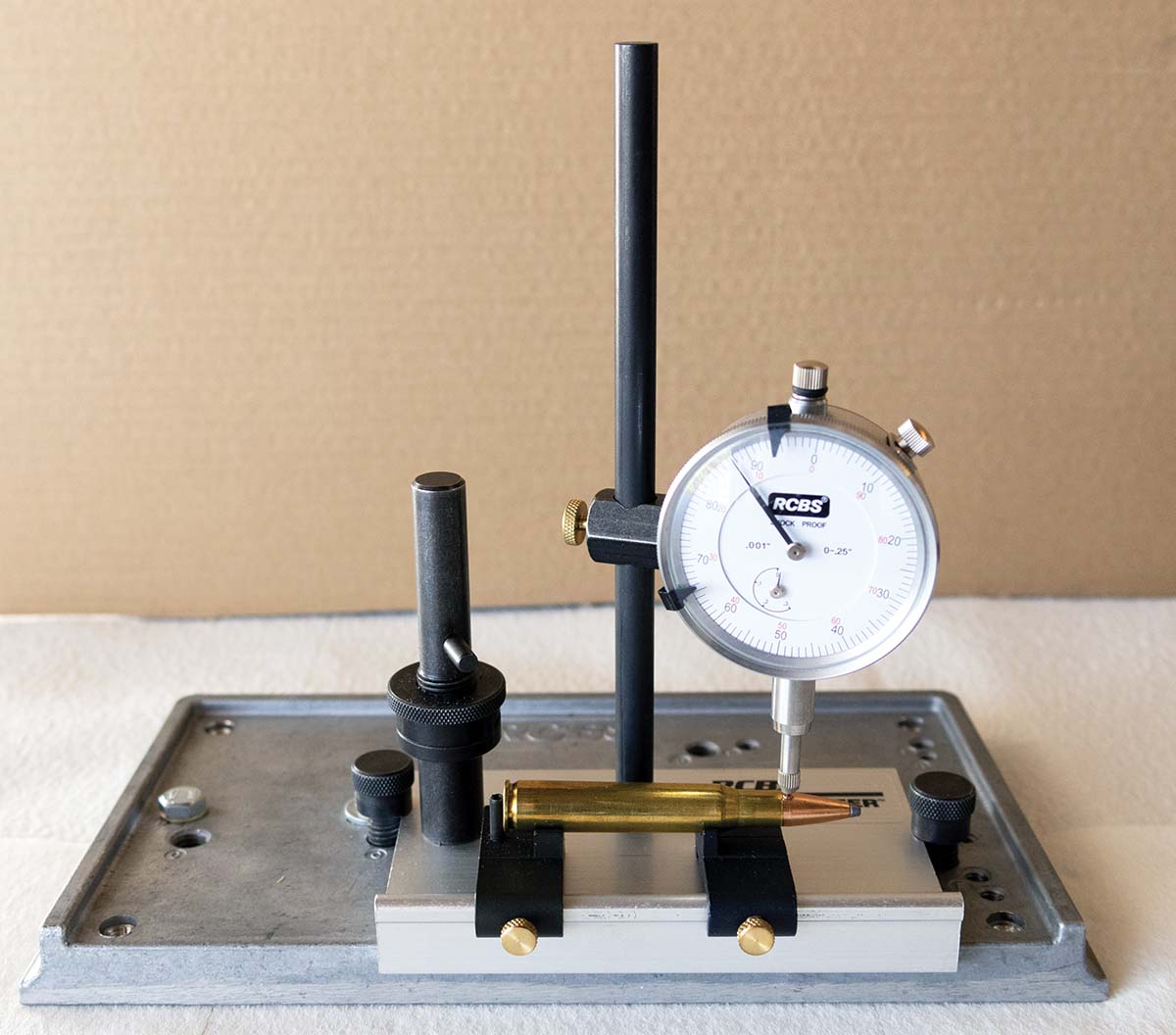

Bullet runout is an easy-to-measure quality indicator for your reloads and a significant factor in achieving the smallest target group size.

As shown in Table VI, the bullet runout of the reloads was significantly better than the commercial ammunition on hand.

.jpg)

The Final Test

The 1903 Springfield had the longest throat among all the test rifles, so it was used to demonstrate the impact of bullet jump on group size. The average group size for three, three-shot groups at 100 yards is included in Table VII, demonstrating the importance of optimizing cartridge length for your rifle and bullet. The data indicates that a bullet jump of approximately .050 inch is a good choice for tight groups with the 1903 Springfield used in this article.

* * *

The following targets illustrate good reload performance at 100 yards with three of the test rifles.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)