Wildcat Cartridges

6.5 Short Action Ultra Mag

column By: Layne Simpson | February, 19

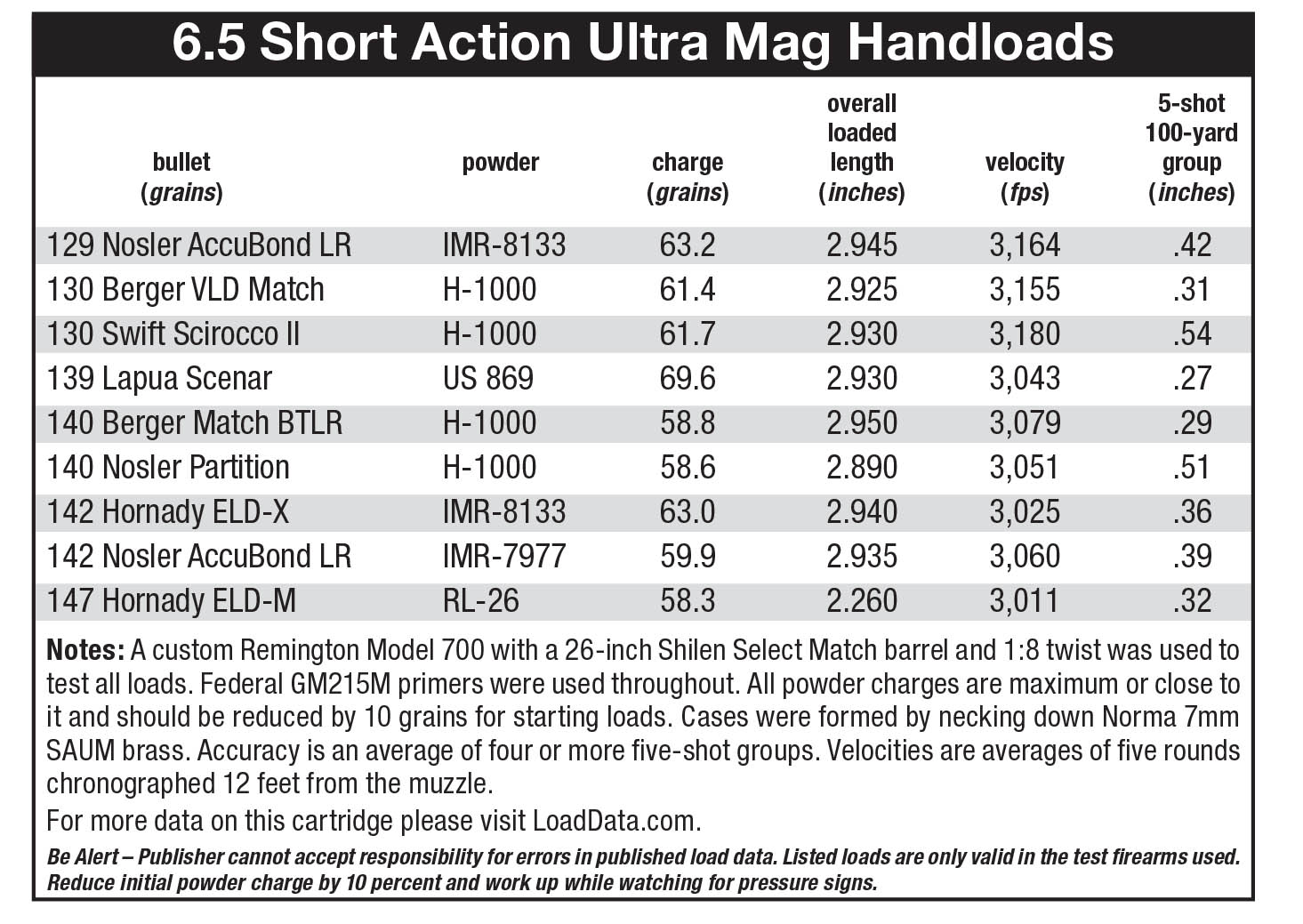

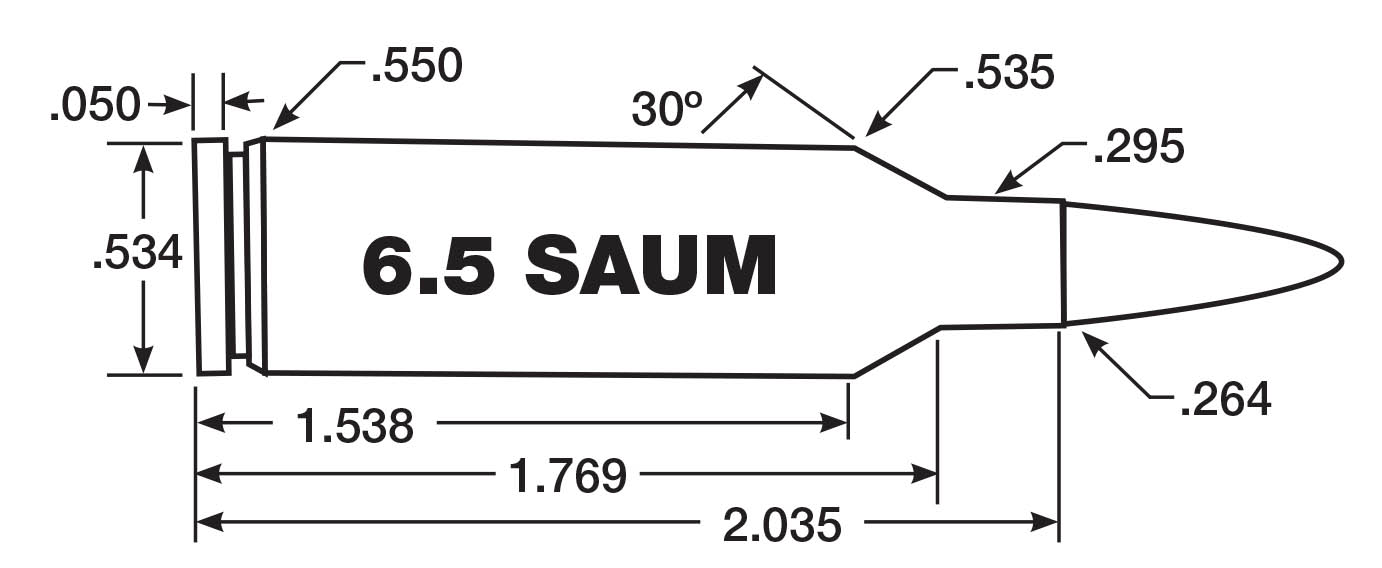

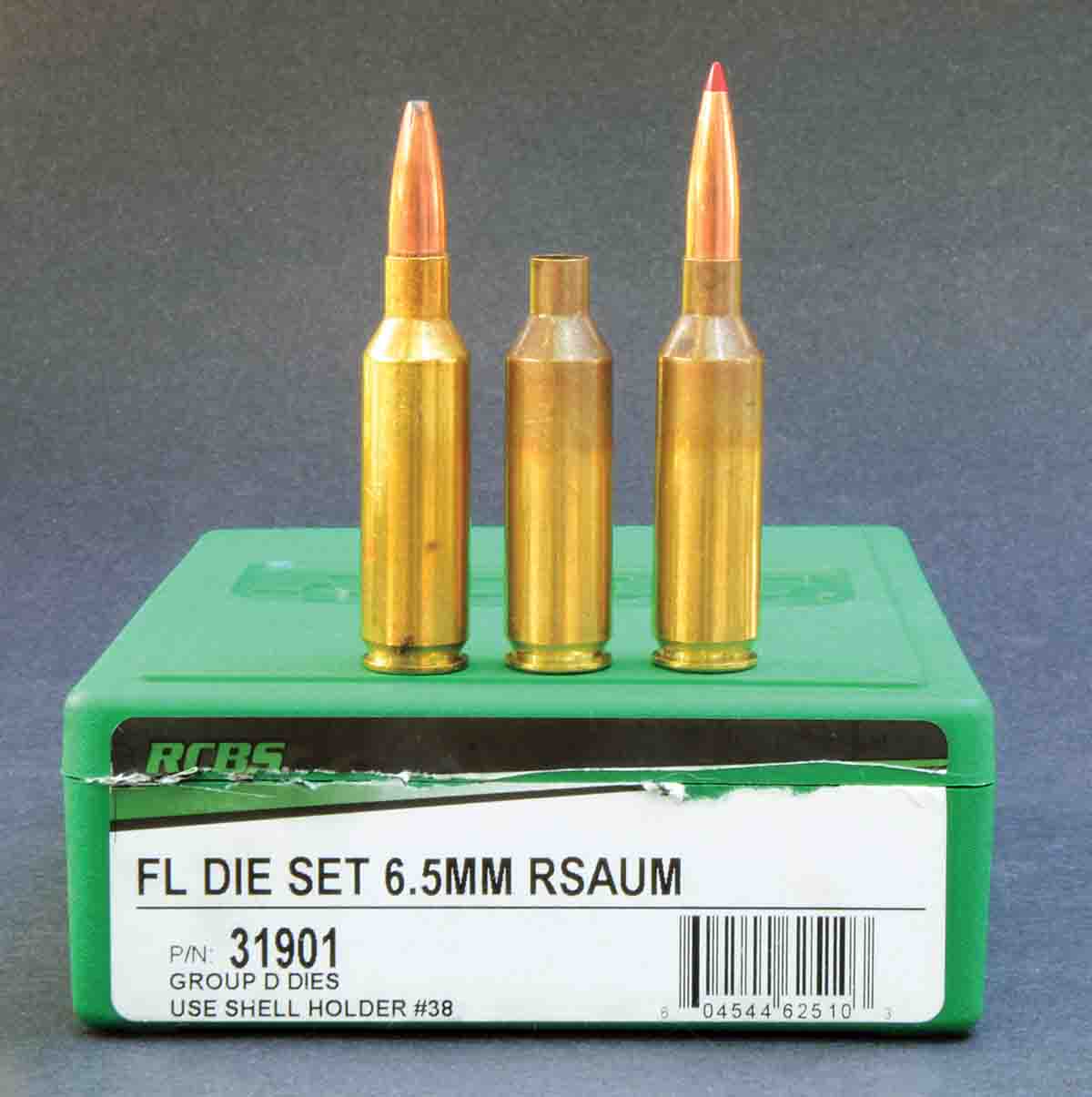

As is often the case with wildcat cartridges, there is more than one version, and the “6.5 GAP 4S” head stamp on Hornady cases differentiates it from the rest. The RCBS dies I have are marked 6.5 RSAUM. Despite the different names, the cartridge originated as the 7mm SAUM case necked down with no other change, and it is more commonly referred to as 6.5 SAUM. Gross water capacity of the GA Precision case is 72.3 grains, or about 4.0 grains more than Hornady’s 6.5 PRC. Cases formed from Remington and Norma 7mm SAUM brass hold a bit less water. As other comparisons go, Hornady 6.5-284 cases hold 64.3 grains while 6.5 Remington Magnum cases made by Remington hold 70.2 grains. The old 6.5-06 case formed by necking down Federal .270 Winchester brass tops out at 66.9 grains, and .264 Winchester Magnum cases on my shelf hold 82.4 grains.

Several different chamber neck diameters are out there. With a .264-inch bullet seated in the 6.5 GAP 4S headstamped case, outside neck diameter is .292 inch. Outside-turning to .291 inch uniforms neck wall thickness. Necked down Norma and Remington 7mm SAUM cases are reduced to the same diameter. When installing a heavy, 26-inch 6.5 SAUM Shilen Select Match barrel on one of my switch-barrel target rifles, I went with a .295-inch chamber neck.

The 6.5 SAUM was intended as a short-action cartridge, but using it in some short actions requires seating long match bullets weighing 140 grains and heavier quite deeply

Installing a Wyatt’s Outdoor extended magazine from Brownells would have increased maximum cartridge length to 3.040 inches, but since punching paper is the intended use of the rifle with its 6.5 SAUM barrel, manually loading cartridges directly into its chamber has proven to be all that was needed.

Chamber throat length also varies. It was originally .120 inch, and GA Precision switched to .081 inch in mid-2013. I settled on .100 inch because it is long enough to allow seating bullets out for minimum intrusion on the powder cavity while also being short enough to allow various bullets to be seated for the amount of free-travel that delivers the best accuracy. It also leaves a bit of room for chasing the rifling as erosion increases throat length.

Hodgdon-1000 has long been the most popular powder among those who handload the 6.5 SAUM, and while it continues to be an excellent choice, it does have competition. The maximum extreme velocity spread to shoot for in a cartridge used for long-distance competition is 10 fps, and H-1000 is certainly capable of that. A member of Hodgdon’s Extreme family of powders, velocity is not affected as much by shifts in ambient temperature as compared to some other propellants. IMR-7977 has a similar burn rate, and it, too, does a good job of ignoring extreme changes in temperature. It is also supposed to reduce copper fouling, and while it should do just that in some barrels, fouling is seldom a problem with any powder in a top-quality barrel. When first shooting the 6.5 SAUM, I along with other shooters was on my own in the load-data department. I now use starting loads listed for the 6.5 PRC on the Hornady and Hodgdon websites.

The 7mm SAUM case can be a pain in the posterior to neck down. Early attempts at running Remington cases through a standard 6.5 SAUM full-length resizing die resulted in collapsed shoulders. An RCBS Gold Medal Match bushing-style, full-length resizer for the 7mm SAUM was already on my shelf, and after a bit of experimenting I found that first squeezing necks down with a .300-inch bushing followed by a .295-inch bushing works fine if the necks first receive a light coat of Imperial Sizing Die Wax. I have not tried necking down .300 SAUM brass, but doing so would likely require additional bushings.