Wildcat Cartridges

6.5 Shooting Times Westerner

column By: Layne Simpson | April, 18

We were being pounded by a frog-drowning rainstorm, and the hillside from which I was shooting prone was so steep and slippery I kept sliding downhill. When I squeezed one off, the bruin dropped dead where it stood and began rapidly tumbling downhill toward us like a big, black sack of Jello. Another hunter in camp later used the rifle and ammunition to bag two equally nice bears.

Sometime during the hunt, Nosler confided in me that his future plans included a rifle built by his company. He would also have his own line of loaded ammunition, and the 6.5 STW would be among the first to be produced. Nosler ammunition became available in 2004, and the very next year the Model 48 Custom Sporter made its debut. But the 6.5 STW was too long for its action, so the .26 Nosler was eventually developed instead.

The idea of necking down the full-length Holland & Holland belted case for .264-inch bullets did not originate on my loading

The new wildcat made its debut in the hands of Wright at the 1961 1,000-yard Leech Cup and Wimbledon Cup matches at Camp Perry. As stated by another competitor who also used a rifle chambered for the cartridge, “It was an immediate winner in a game formerly dominated by .30 magnums.” Most of those early benchrest and big-game rifles were built by Al Hoyer, whose shop was located in Mifflintown, Pennsylvania. And since the cartridge was created by necking down a case of Weatherby design, it was given the name, 6.5-300 Weatherby-Wright-Hoyer (6.5-300 WWH). If this sounds familiar it is because the 6.5-300 WWH is the exact cartridge recently introduced by Weatherby as the 6.5-300 Weatherby Magnum. For more on the 6.5-300 WWH and its development, I refer you to Robert Hutton’s report in the 1965 Gun Digest and a more in-depth article by Earl Etter in Rifle No. 18 (Nov/Dec 1971).

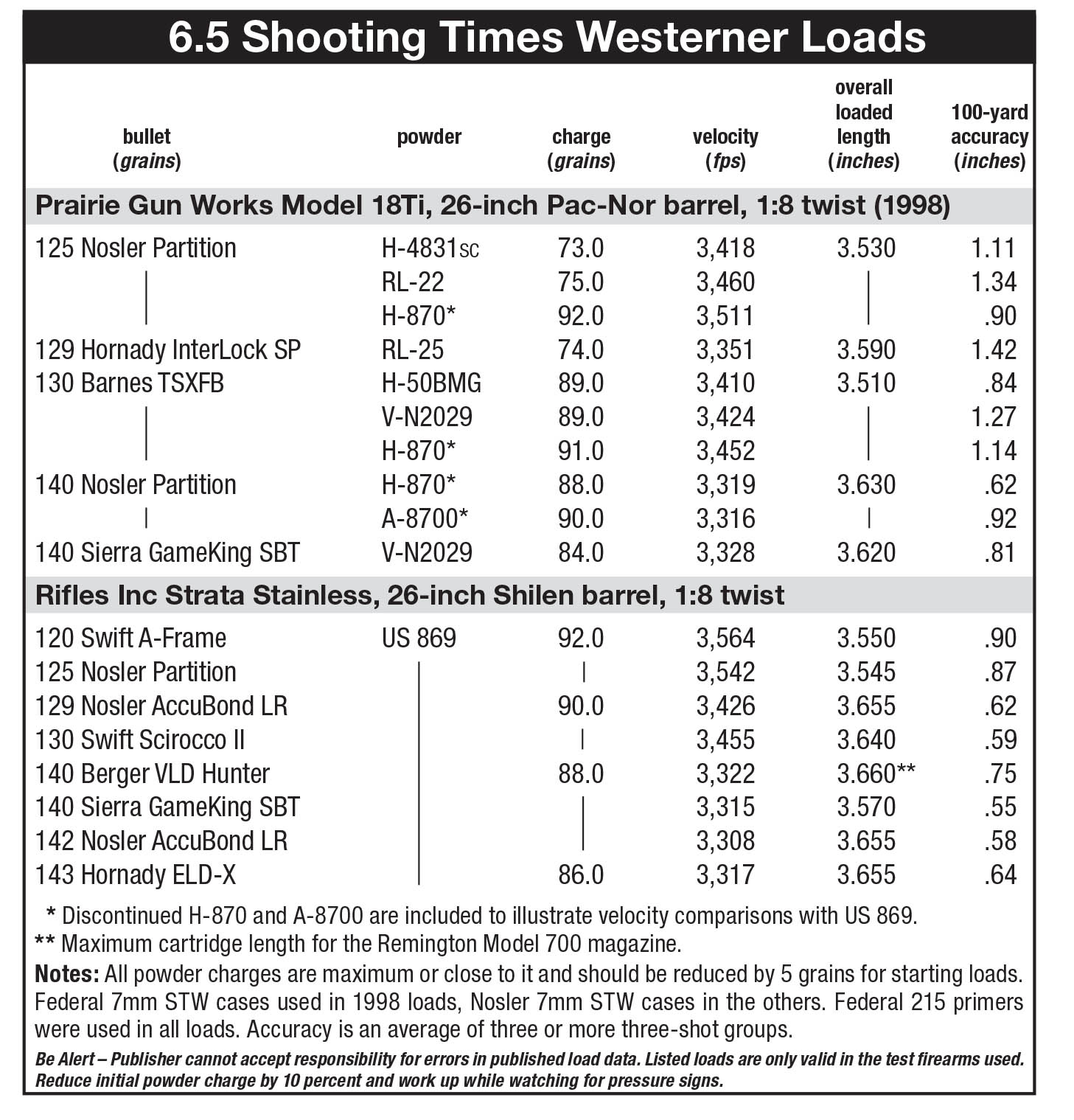

While developing loads for the 6.5 STW back in 1998, I recalled that military surplus H-870 was a popular 6.5-300 WWH powder among 1,000-yard competitors during the 1960s. It and another surplus powder, Accurate 8700, also delivered top velocities along with excellent accuracy in the 6.5 STW. Those who used the 6.5-300 WWH also preferred to neck down and fireform Winchester-Western .300 H&H Magnum brass because it withstood more maximum-pressure firings than the softer Weatherby brass. Forming the 6.5 STW from .300 H&H is not difficult, but cases have to be fireformed before maximum charges can be used, and they last no longer than Nosler and Hornady 7mm STW cases necked down. Quality Cartridge offers 6.5 STW cases with the proper headstamp, but I have not gotten around to trying them.

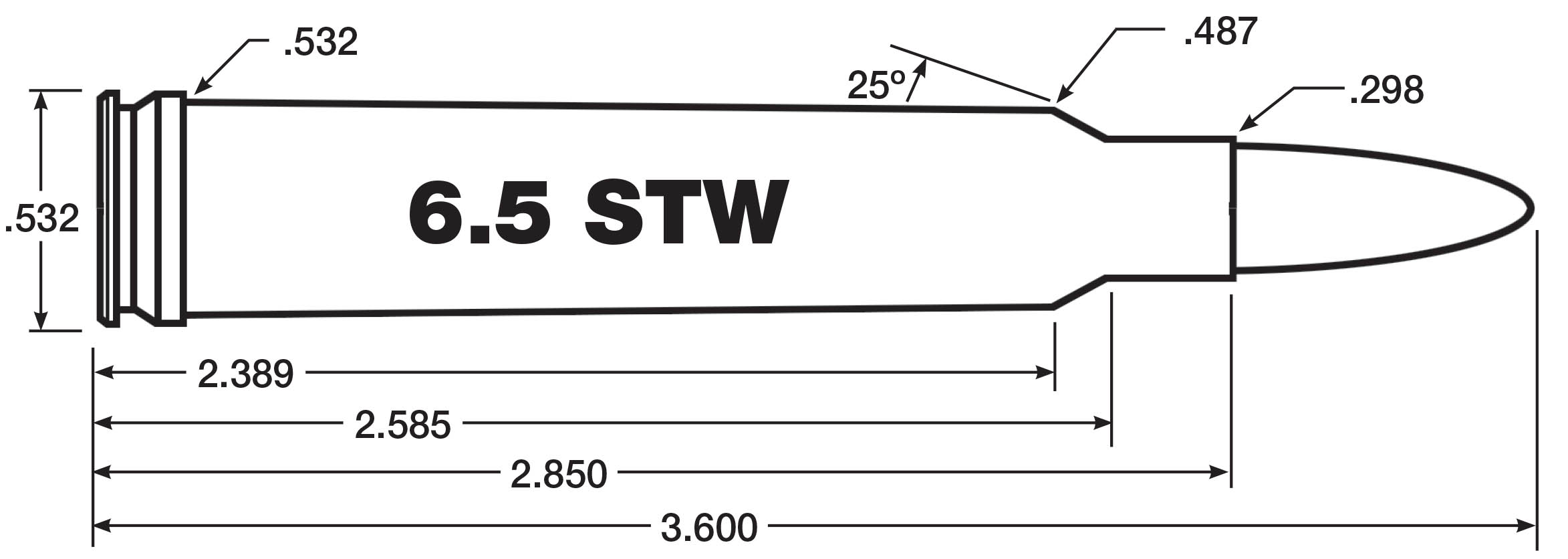

So how does 6.5 STW performance stack up against its competition? Filled to the brim with water, gross case capacities are 96.7 grains for the STW and Weatherby, and 98.2 grains for the Nosler case. A comparison of gross capacities is informative, but comparing net capacities with the same bullet seated in all three is a bit more meaningful because it is a better indicator of how much powder can be safely burned. With the Nosler 129-grain AccuBond LR seated to an overall cartridge length of 3.600 inches for the STW and the Weatherby, and 3.340 inches for the Nosler, net capacities are 92.1 grains for the Nosler cartridge and 90.2 grains for the other two. Those figures were arrived at not by calculating how much water was displaced by a seated bullet, but by seating a bullet in an unprimed case, weighing it, and then weighing it again after putting a small hypodermic syringe through the flash hole to fill the powder cavity with water.

Regardless of which is chosen, keep in mind that extremely-low-expansion-ratio cartridges are usually seen at their best when operating at maximum pressure, or close to it. An unacceptable level of velocity spread can be caused by a number of factors, with use of a primer that is too mild and inadequate case neck tension on bullets being a couple. All of the handloads listed here use the Federal 215, but CCI 250 and Winchester Large Rifle Magnum primers are also quite good.

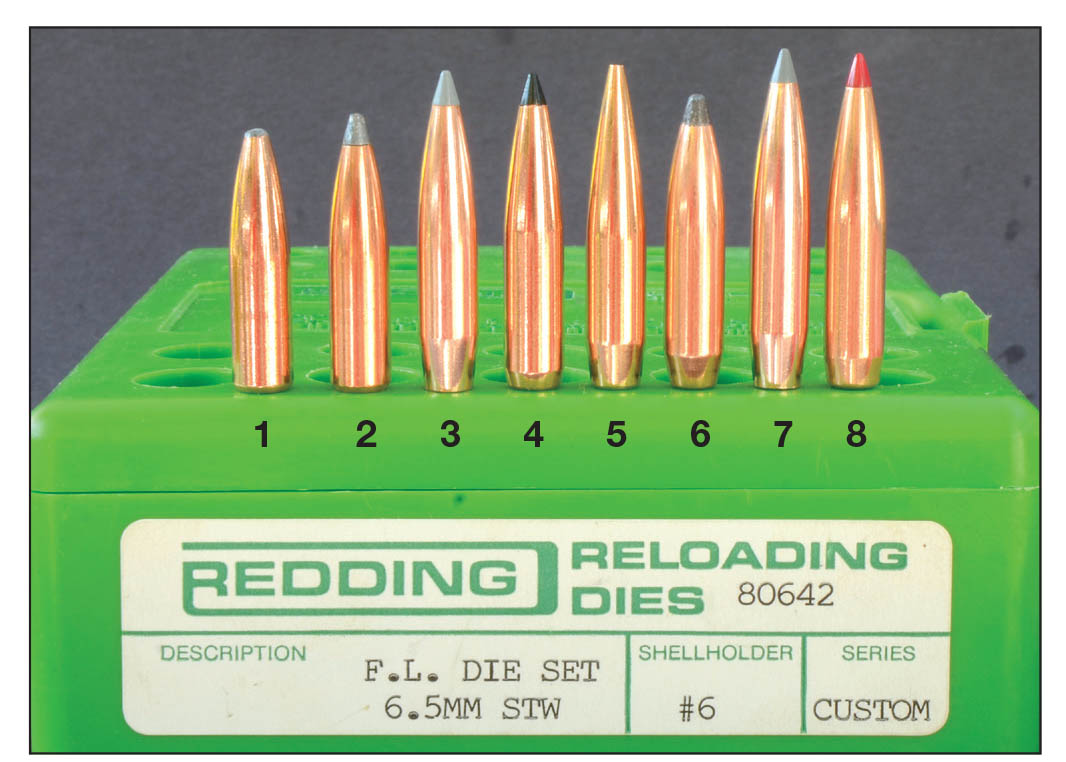

If necessary, case neck tension can be increased by reducing the diameter of the expander ball in a resizing die by .001 to .002 inch. Perhaps even better is to use a Redding Type-S bushing-style resizing die with a bushing .003 to .004 inch smaller than the neck diameter of a loaded round.