Propellant Profiles

Alliant e3

column By: Randy Bimson | June, 21

Red Dot was “the target load propellant” when I started reloading target-load shotshells. It was my, and most every clay-target shooter’s, go-to target load powder for years prior to the wholesale transition of the industry from paper hulls, and oh, I so miss the aroma of paper hulls compared to those “hard-kicking” plastic hulls. Every reloader was then on a mission to find a powder that would “tame” the plastic hulls and the high energy per grain, as the comparatively low chamber pressure DuPont 700-X was the train to be on. Somehow, I let the “more experienced” reloaders convince me, against my better judgement and Isaac Newton’s laws of motion, which quantify that for a given payload weight and muzzle velocity-free recoil will be the same regardless of differences in chamber pressure.

To paraphrase a statement attributed to Bruce Hodgdon years ago, “You shoot clay targets to break them, not to come home with the bore of your barrel clean.” Well, Hodgdon heard otherwise from its customer base who not only wanted to break 100 straight, but also wanted to come home with a relatively clean barrel and if they happened to be shooting an autoloader, minimal propellant debris in the shotgun action.

Hodgdon took that to heart, and in 1992 partnered with Thales/ADI, an Australian propellant manufacturer, and introduced Hodgdon Clays. Prior to the advent of Clays, it was said that Hercules/Alliant left their calling card, the “dot” red residue from Red Dot powder, covering the ground at every station of every major shotgun event. Clays gave the target shotshell reloader an ultraclean-burning propellant with minimal muzzle flash and a consistent burn. Clays became an unparalleled staple of trap, skeet and sporting clay shooters, and I must confess that I have shot tens-of-thousands of shells at targets I have loaded with Clays.

If Hodgdon’s introduction of Clays was a shot across the bow, Alliant returned fire when it introduced the game changer target load shotshell propellant, e3. Alliant applied the technologies gained in the development of the Improved Red Dot, Green Dot and Unique, along with other proprietary incremental changes in technologies and material processing to develop a target load shotshell propellant that combines the best attributes of the “three amigos,” Red Dot, 700-X and Clays, all wrapped up in a singular product.

Alliant’s naming convention, e3, encapsulates the attributes: Energy – the high energy to low charge weight as exhibited by 700-X; Efficiency – exhibits the high density and good flowability of Red Dot; Excellence – the first time I shot shells loaded with Hodgdon Clays, I was amazed at how clean my barrels were, and how clean the trigger group of my workhorse Beretta autoloader stayed. When I shot similar loads with e3 I was astounded at how clean my barrels remained and how clean my Beretta autoloader trigger group and action was.

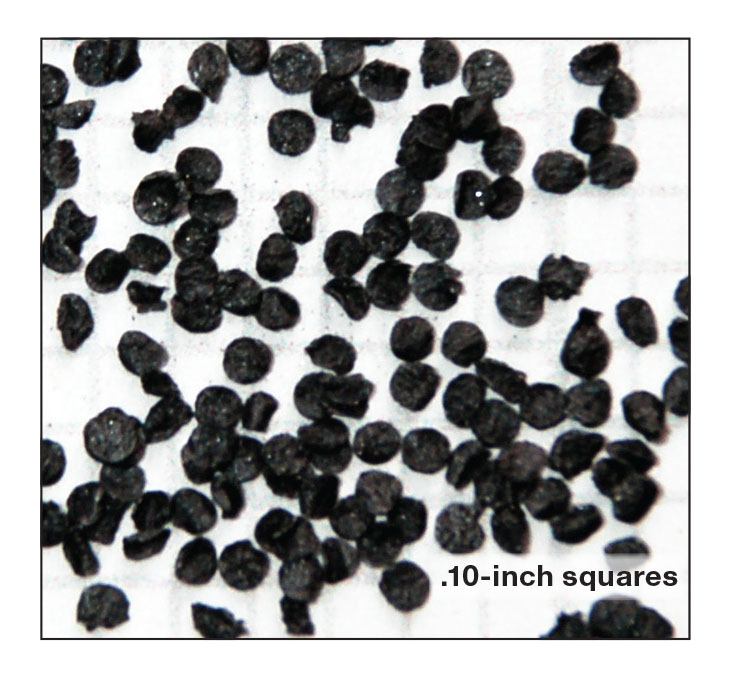

Like most of the propellants manufactured for Alliant Powders by New River Energetics in Radford, Virginia, e3 is a double base propellant powder with a nitroglycerin content of 30 percent. This makes it one of the highest energy target shotshell propellants offered as canister powder. Of the powders referred to in this article, Alliant e3 has the fastest burn rate. The Material Safety Data Sheet describes the appearance of the granules as “small black/gray flakes.” To my magnifying glass-aided eye, I would describe them as medium to dark gray colored miniscule “potato chips,” right down to the wavy chip shape. The “chips” are a nominal .063 inch in diameter with a .004-inch web thickness. The bulk density of e3 is 0.48g/cc.

Flow characteristics are a major concern for shotshell reloaders as we use single stage or progressive reloading presses that incorporate some type of volumetric powder dispensing system. The two reloading presses I used in assembling loads with e3 included a high-volume Dillon SL900 progressive that does everything except load the wad on the machine and a Ponsness-Warren (P-W) 375 Du-O-Matic. Both are trusted machines. The P-W 375 has been on my loading bench since the mid-1970s, and the Dillon since 1995. The Dillon incorporates a slide-type charge bar while the P-W uses a rotary disc-type shot and powder dispensing system. Of the two presses, the P-W is the most susceptible to powder granule migration, likely because the top plate of the rotary disc is secured at the center of the plate while the powder bushing is located on the outer edge of the plate.

The design engineer in me believes that the pressure to seal the disc is greater at the center of the disc and lesser so at the outer edge, where the powder bushing is located. Be that as it may, the P-W exhibits gobs of powder migration with most spherical powders; little powder migration with Red Dot and 700-X, very little with Clays and virtually none with e3. The Dillon charge bar system showed virtually no leakage of e3 as well. In addition, over the course of loading 100 rounds on each press with e3 and weighing each press-thrown charge, charge weight variation was a super consistent, plus or minus 0.1 grain from either press.

When it comes to propellants, I admit that I have been guilty of having a “If it is not broke, don’t fix it” attitude. If I have a load that patterns, or in the instance of a rifle or handgun, groups exceptionally well, I find little incentive to change just for change’s sake. But, and that is a big “but,” changes in technology are what I thrive on, and when someone offers product that may enhance my current performance expectations for any particular cartridge I load for, I will be first in line to give it a try.

For the past 10 years I have been loading skeet loads exclusively with e3, not just for change’s sake, but because it meters so well. There is virtually no powder migration, and it is every bit as clean-burning, if not more so in my experience, then the former “best-in-category” leader Hodgdon Clays. In my experience, I have also found it very cost effective.

Shot patterns are the result of the multiple interactions of the shotgun and ammunition components. The combination of a particular barrel, choke/choke tube, primer, powder, wad, make and hardness of shot all combine to affect how the gun patterns with any particular load. That being said, I found it a minimal amount of work, with three shotguns, to build loads with e3 that give exemplary patterns for the intended clay target sport.

Alliant e3 is a versatile 12-gauge specific target load powder. Its economical, efficient and incredibly clean-burning. It is available in 1- and 4-pound canisters and 8-pound kegs. If you are a clay target shooter or like the comfort of light hunting loads, try e3, I think you will find it a very useful addition to your powder inventory.

.jpg)