Propellant Profiles

Winchester WinClean 244

column By: R.H. VanDenberg, Jr. | February, 23

Winchester 231 has built an enviable reputation for delivering guilt-edge accuracy in target loads and excellent ballistic performance combined with low muzzle-flash signature in service loads. There is a well-warn cliché “if it is not broken, don’t fix it.” In January 2018, Winchester defied that age-old cliché with the introduction of Winchester WinClean 244 pistol powder.

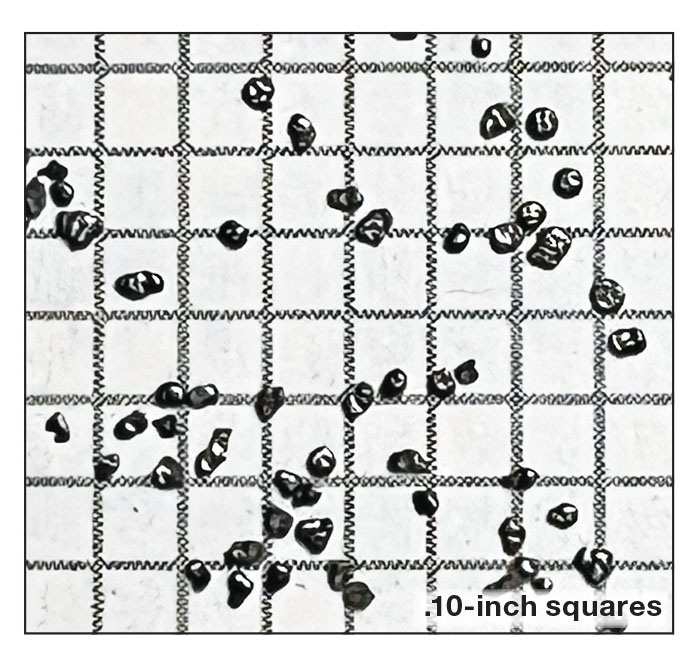

A double-base Ball powder produced under contract at General Dynamics’ St. Marks Powder mill, WinClean 244 sits in the No. 31 spot on Hodgdon’s burn rate chart, between ever so slightly faster burning W-231, in the No. 29 spot, and slightly slower burning Alliant Unique, in the No. 32 spot. Physically, WinClean 244 is very hard to distinguish from W-231 and great care should be taken to ensure that no two powders are on the loading bench at the same time, where there is the possibility of inadvertently interchanging them. WinClean 244’s granular structure is the familiar “flattened spheres” shape of numerous of the spherical powders, as is the gray/black color of the granules. Dimensionally, the WinClean 244 granules measure a nominal .0117 inch to .0469 inch in diameter with a web thickness of a nominal .0090 inch, whereas W-231 granules diameter is a nominal .0225 inch with a nominal web thickness of .0090 inch. The nitroglycerine content of WinClean 244 is 37 percent, plus or minus, while W-231 is a nominal 22.5 percent. The bulk density of WinClean 244 is .80 g/cc where the bulk density of W-231 is .70 g/cc. Note that this in no way is meant to imply that WinClean and W-231 load data can be used interchangeably, that is not the case.

Handgunners are notorious for long shooting sessions, particularly those that shoot any of the action- shooting venues. That combined with the increased use of fully copper-plated encapsulated bullets leads to more time spent cleaning copper fouling out of barrels and powder residue from actions. WinClean 244 builds upon W-231’s legendary excellence as an exceptional handgun cartridge propellant and adds to it the chemical wizardry of Winchester’s proprietary WinClean additive(s) to actively reduce accuracy-robbing copper-fouling and reduce powder fouling that can compromise the mechanical function of the semiautomatic pistols so commonly in use today.

How does this work out in the real world? I used my two most accurate semiautomatic pistols, my Smith & Wesson Model 52-2 Master and my Smith & Wesson Performance Center 952-1, to test and evaluate WinClean 244. I used previous developed benchmark loads using W-231 as my comparative standard. All accuracy testing was done at 50 yards with 10-shot groups fired from the industry-standard Ransom Master Series handgun machine rest. When I changed from one pistol to the other, to ensure consistency, I fired a 10-shot group to seat the pistol frame in the Ransom Master grip inserts prior to shooting for record.

For those not familiar with the Model 52-2 Master, it was designed from the ground up as bullseye handgun and shoots only the .38 Special midrange full-wadcutter cartridge. The Model 52 is acclaimed to be one of the most accurate centerfire semiautomatic pistols ever made. My Model 52 will consistently shoot 10-shot groups that average 1.750 inches at 50 yards from the Ransom with its favorite W-231 load: 3 grains of W-231, Federal 100 Match Small Pistol primer, 148-grain cast-lead wadcutter bullet dropped from a Hensley and Gibbs (H&G) No. 251 six-cavity mould. The cartridges are assembled in cases sorted by make, trimmed to 1.145 inches and crimped using a Lyman taper crimp die.

In working up the .38 Special wadcutter loads with WinClean 244, I focused on using two of the most consistently accurate .38 wadcutter bullets that I have experience with, the Remington 148-grain swaged lead hollowbase wadcutter and quality cast bullets from the previously mentioned H&G’s No. 251 six-cavity mould.

WinClean 244 nearly, but not quite, bested the above W-231 benchmark load. After testing various powder charges from the suggested starting load of 2.5 grains to Hodgdon’s maximum recommended load of 2.8 grains of WinClean 244, my S&W Model 52 settled on 2.5 grains of 244 as its favorite. The average of five, 10-shot groups came in at 1.790 inches.

The average velocity of the both the 231 and 244 loads, shot from the Model 52, comes in just over 700 feet per second (fps), 710 fps and 715 fps respectively. Regardless of bullet make and powder type, my Model 52’s accuracy sweet spot seems to be loads that fall in the 700 to 725 fps range.

Switching over to the S&W Model 952-1, the 952 is, in essence, the S&W Model 52 reincarnated in the 9mm Luger chambering. This is one of some 1,735 Model 952s built over a 10-year span back in the heyday of the Smith & Wesson Performance Center. When S&W announced the introduction of the Model 952, they advertised it as being “the most accurate 9mm in world” at the time. That is a heady statement to back up. Having previously owned a Swiss-built 210-6, a Browning High Power Competition, a Walther GSP/.32 S&W Long wadcutter, and a Sako Trice/.32 S&W Long, all contenders for an accuracy crown, I can attest to the 952’s superlative accuracy.

How did WinClean 244 stack up against W-231 in the 9mm Luger? It hit the ball right out of the park. Bullets used for the test purpose were the Sierra 115- and 125-grain FMJ Tournament Master, the Hornady 115- and 125-grain HAP (Hornady Action Pistol) and the 125- and 147-grain XTP and the Speer 147-grain TMJ and the 124-grain Gold Dot.

My gold standard W-231 9mm load I have developed for the 952 is as follows: 4.4 grains W-231, Winchester WSP Small Pistol primer, Hornady 125-grain HAP bullet, cases sorted by make and trimmed to .752 inch and taper crimped using an RCBS taper crimp die. Average chronographed velocity of this load is 1,055 fps and accuracy is right up there with the Model 52 at 50 yards, with 10-shot groups averaging 1.850 inches.

The best WinClean 244 load for the 952? Try 4.1 grains of WinClean 244, Federal 100M match Small Pistol primer, and the Sierra 125-grain Tournament Master bullet set a new accuracy load standard of five, 10-shot groups averaging 1.799 inches at 50 yards from the Ransom Rest! The average velocity of this load is a very respectable 1,089 fps. Truly a homerun for a 9mm Luger chambered pistol.

Does WinClean 244 live up to its “WinClean” name. It does in my books. Starting with a clean bore, I found that after an extended range session shooting WinClean powered loads, cleaning sessions were minimal and I was back to having a shiny silver bore. Action area clean-up was much less involved as well with the WinClean 244 loads producing noticeably less fouling than the 231-powered loads and significantly less than Bullseye loads I have shot on other occasions.

I will not give up on using W-231 as the preferred propellant for cartridge/handgun combinations that I have established benchmark loads for because as they say, “if it is not broken, don’t fix it.” This old dog can learn new tricks and I assure you that when I find WinClean 244 loads that establish benchmark-accuracy loads, like the load for the S&W 952 listed above, I will jump ship and use WinClean 244 in a heartbeat. Move over W-231 and make room for WinClean 244!

.jpg)