I have two rifles chambered for the grand old .300 Holland and Holland Magnum cartridge. The first to come into my possession, “Brutus,” as it was named by one of my hunting buddies, is a fine pre-’64 Winchester Model 70. The two of us have been inseparable hunting partners for some 51 years. Not that I will retire Brutus anytime soon, but it is good to have an understudy. The youngster is a fine Sako Model 85 and its history should not be lost to time, or surely there will come a day when Sako afficionados will question its authenticity touting that the Sako Model 85 was never chambered for the big .300 Holland and Holland Magnum by Beretta Holding Group, the corporate parent of Sako. This rifle, quite possibly the rarest Sako 85 in existence, bears the inscription in script on the left side of the barrel,

.300 Holland and Holland Mag. and on the right side,

Sako Custom Shop #001. Here is how it came to be.

The Beretta USA/Sako Custom Shop marking. Number 001, the one and only.

In 1999, Sako came under the corporate umbrella of the Beretta Holding Group. During my time with Beretta USA, I was privileged to take part in many special projects. In 2005-06, Christopher Merritt, then general manager of Beretta USA, started to discuss the idea of a Beretta/Sako custom shop that would be located here in the U.S. I was drawn into the conversations early on since I was previously responsible for securing the services of the very talented gunmaker, Jim Brockman, of Brockman Custom Gunsmithing located in Gooding, Idaho. Jim had learned the trade through an apprenticeship at the famous Mauser works in Oberndorf, Germany, in the early 1970s and he was the only gunmaker stateside that I entrusted to do the most challenging work on the likes of the bespoke Beretta 455 EELL, hand-detachable, sidelock-double rifle.

The reverse of the barrel with the caliber marking.

As the discussions moved forward, it was determined that we would need to do a “proof of concept” project. It just so happened Beretta USA management was looking at the possibility of working with Safari Club International on a fundraising project. I suggested that this could be a very good springboard to introduce the proposed Beretta USA Beretta/Sako custom shop. The concept would be 10 pairs of custom-built Sako Model 85 rifles with each set comprised of a .300 Holland and Holland and a .375 Holland and Holland rifle.

The decision was made to design and build one rifle as a proof of concept. I was assigned the responsibility for the design of the proof-of-concept rifle and management of the project. The .300 Holland and Holland Magnum was the chosen cartridge and the rifle would be patterned after the British express rifles that where so popular in the Highlands of Scotland and the veldts of Africa prior to World War II. The new rifle was christened the Sako Model 85 Highlander.

Nosler’s 200-grain Partition bullets deliver. A tight 1.671-inch group wih five-shot groups at 200 yards.

The ensuing rifle was a collaboration between me, conceptualizing the design, and Jim Brockman, executing the build under a commission placed by Beretta USA. As no actions-only were available from Sako at the time, the project rifle was built on an action taken off a Sako Model 85 Hunter chambered in .375 H&H Magnum.

The rifle features a 26-inch barrel with a recessed target-type crown turned from a Lilja Precision Rifle Barrels blank and fitted with barrel-band sling swivel and English-style banded front sight ramp and hood. The front sight proper is a gold-faced Patridge-style made by Jim.

Those familiar with Sako will immediately notice the apparent absence of the factory integral Sako scope-mount dovetails, which are neatly covered by Jim’s custom-made scope-mount bases, which smooth the lines of both the front and rear receiver rings. The receiver rings now accommodate 30mm Talley Manufacturing quick-detachable lever rings fitted with what I think is one of the best Burris scopes ever built, the made-in-USA Euro Diamond 1.5-6x 42mm with the illuminated No. 4 German-style three post and crosshair reticle.

A much-used Hart Bench Rest and Randy’s favorite spotting scope, a Bausch and Lomb 30x BALscope SR. in a Freeland stand.

Readers may notice on the accompanying photos that while there is a front sight, there is no apparent rear sight. Jim incorporated a fully adjustable spring-loaded “pop-up” aperture rear sight, of his design, into the rear receiver ring scope-mount base. Just remove the scope and the aperture sight “pops up” and is ready to use. Very ingenious!

Shooting the 200-grain Nosler loads from the bench.

The stock is a handsome piece of Turkish walnut, nicely figured through the buttstock, straight-grained through the grip and forend as one would want, with a very classic multi-panel checkering pattern, a beaded cheekpiece with shadow-line, black recoil pad and ebony forend-tip, and steel pistol-grip cap, trigger guard, and bottom metal as befits a rifle of this class. Two crossbolts reinforce the action area. The stock finish is a classic, hand-rubbed oil, and the metalwork is finished in the very appropriate rust/blue finish. No black oxide bluing here.

Chronographing loads using Oehler Precision’s 35P with the Skyscreen III Proof Channel.

Given a choice between a bolt-action hunting rifle with a hinged-floorplate magazine, or a detachable box magazine I would have, until now, chosen the hinged-floorplate magazine every time. One must try very hard indeed to inadvertently lose the hinged-floorplate and associated parts. Detachable box magazines on the other hand are just waiting to either be lost or forgotten at home.

The buttstock highlights the very nicely figured Turkish walnut and the beaded cheekpiece with shadow line is a nice classic touch.

I love the Sako 85s detachable box magazine and the patented total control magazine latch system. Whether carrying the rifle by hand, shoved in a saddle scabbard, or subject to heavy recoil, it is virtually impossible to unintentionally release the Sako 85’s detachable box magazine from the rifle. To release the magazine, it requires the magazine be pushed upward into the rifle slightly before the magazine latch can be pressed rearward to release the magazine. I have read where some writers have called it a “pain in the rear” and others who say it takes two hands to remove a magazine from the rifle. I am not sure what world those folks are from, but I can easily remove the magazine from a Sako 85 with one, cold-numbed hand, no problem.

A closeup of Brockman’s innovative integral pop-up aperture sight tucked neatly below the scope just forward of the power change ring.

The finished Sako Model 85 “Highlander” is a looker and it shoots as good as it looks. I was fortunate to have the privilege to accompany Actor Gerald McRaney to Namibia in 2008 to film a segment of the World of Beretta television series. Gerald wanted to fulfill a long-time desire to take a leopard and I was looking for an exceptional kudu, oryx and warthog. Federal Cartridge was the ammunition sponsor for the World of Beretta series and graciously supplied its Vital-Shok .300 H&H Magnum round loaded with the excellent 180-grain Barnes Triple Shock bullet. That load constantly produces sub-¾-inch, five-shot groups off the bench at 100 yards.

This is an overview of Brockman’s custom scope mount and the innovative integral pop-up aperture sight.

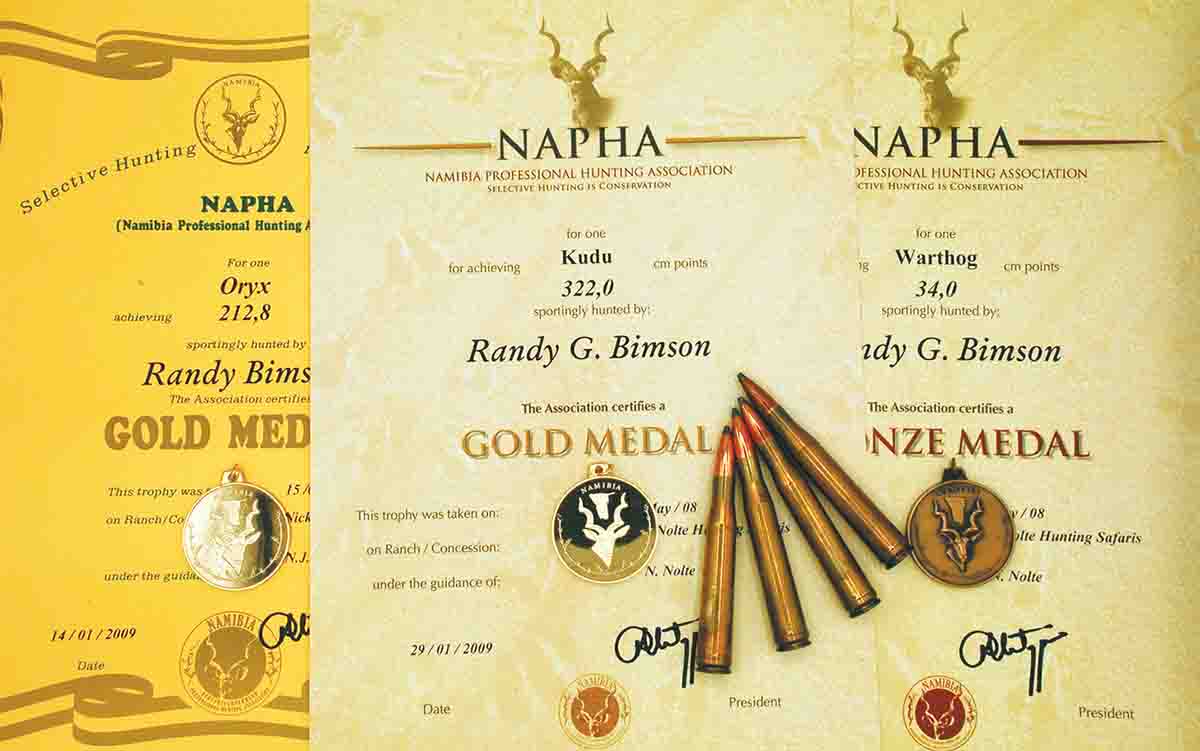

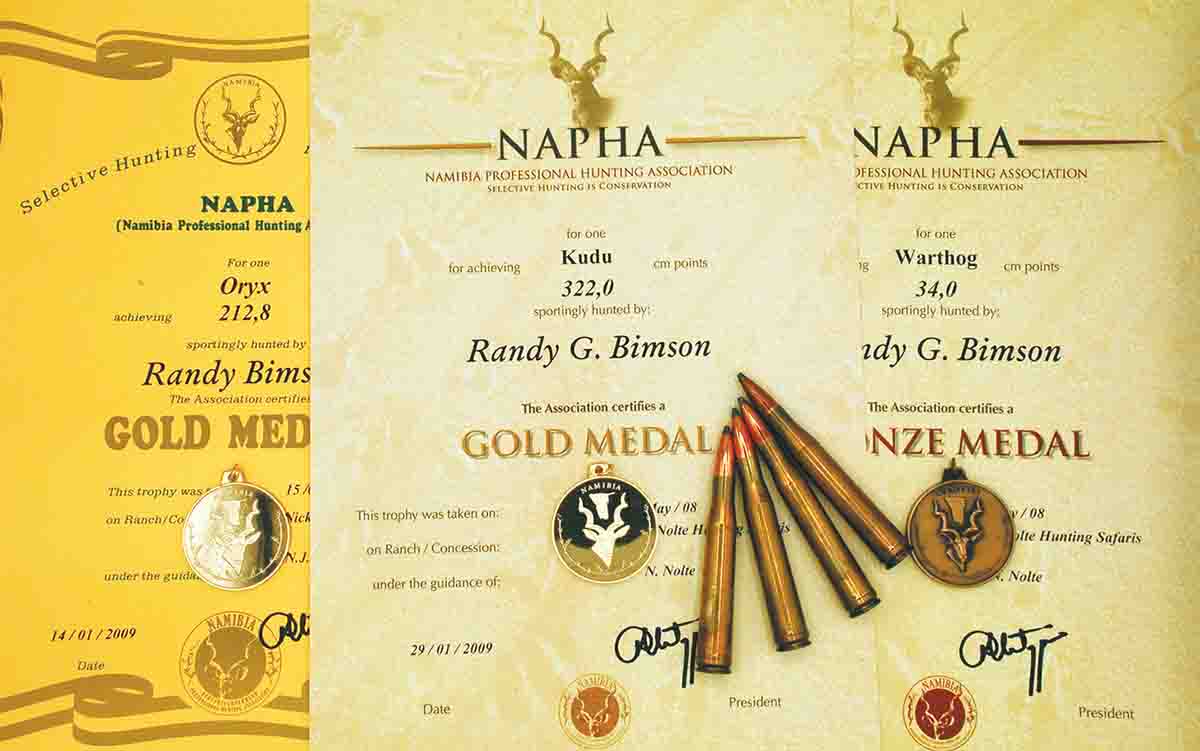

The Highlander accounted for a beautiful old bull kudu, a gray ghost, with one shot, scoring more than 61 inches a side for a total of 126¾ inches This earned a gold medal from the Namibia Professional Hunters Association (NPHA); a grand bull oryx earned another gold medal with a total score of 83¾ inches with two shots. The professional hunter said it was dead on the first shot, but my orders were “if the animal does not fall to the ground on the first shot, shoot it again.” The two bullet entrance holes were an inch apart. One of my favorite African animals, the lowly warthog, resulted in bronze medals – one at 13.4 inches and one at 11.8 inches. In addition, a local church had two permits from the game department for two non-trophy, mature bull oryx to supply meat for a special event, which I was given the privilege of harvesting, using a single round each. The Highlander had proven itself a very capable hunter. Also, Gerald fulfilled his lifelong quest with an exceptional leopard.

Here is a shooter’s view of Brockman’s innovative pop-up aperture sight, built integral to the custom scope mount.

Corporations can take considerable time to birth a project and the Beretta USA/Sako custom shop idea was one of those projects. A year after the Namibia trip, Merritt stepped down as general manager of Beretta USA, and with him, left the driving force to create a Beretta USA/Sako custom shop. The Sako 85 Highlander and the Beretta USA/Sako custom shop, were destined to never be, except for one.

On my return from the Namibia trip, the Sako Highlander took up residence in my office at Beretta USA, where I was its official custodian. Over the next couple of years, we enjoyed each other’s company at the rifle range and on the occasional hunting trip here in the states. With the custom shop project dead in the water, when I left Beretta to accept the director’s position at the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI), Beretta management gave me the opportunity to purchase the unique and one-of-a-kind Sako Highlander and of course I did. The sales invoice description tied to the receiver serial number reads “Sako 85 Hunter, .375 H&H Mag, JRS1A37.” JRS1A37 being the product code before the rifle was stripped for its action. What recorded history Sako, or Beretta USA have on this one-of-a-kind Sako Highlander is likely interned in archives or destroyed by now.

The Sako Highlander first drew blood with factory loaded ammunition supplied by Federal Cartridge, but since then the Highlander’s diet has been exclusively handloaded ammunition.

Some of the recognition the Sako Highlander has earned in the hunting field.

It seems that whenever handloading for the .300 H&H cartridge is mentioned in print there are howls of anguish. The long, gently sloping shoulder is accused of causing excessive case stretch, which in turn, leads to frequent neck trimming at best and case head separations at worst. My response to that it is “Give it a break!” It does not matter if the case is rimless, rimmed or belted. If a handloader needlessly pushes the shoulder back every time they resize the case then, yes, case life is going to be “the pits.” Setting up the sizer to just touch, or ever so slightly bump the shoulder, by using the old smoke carbon on the shoulder, or my preferred way, using the L.E. Wilson Tool adjustable case gauge and the case life is very good. Others berate the .300 H&H case design as antiquated and inefficient. Not so folks. When one looks at the ratio of powder-to-velocity, the Holland was, and still is, the most efficient .300 magnum case out there and with today’s new propellants, it nips right at the heels of the newbies.

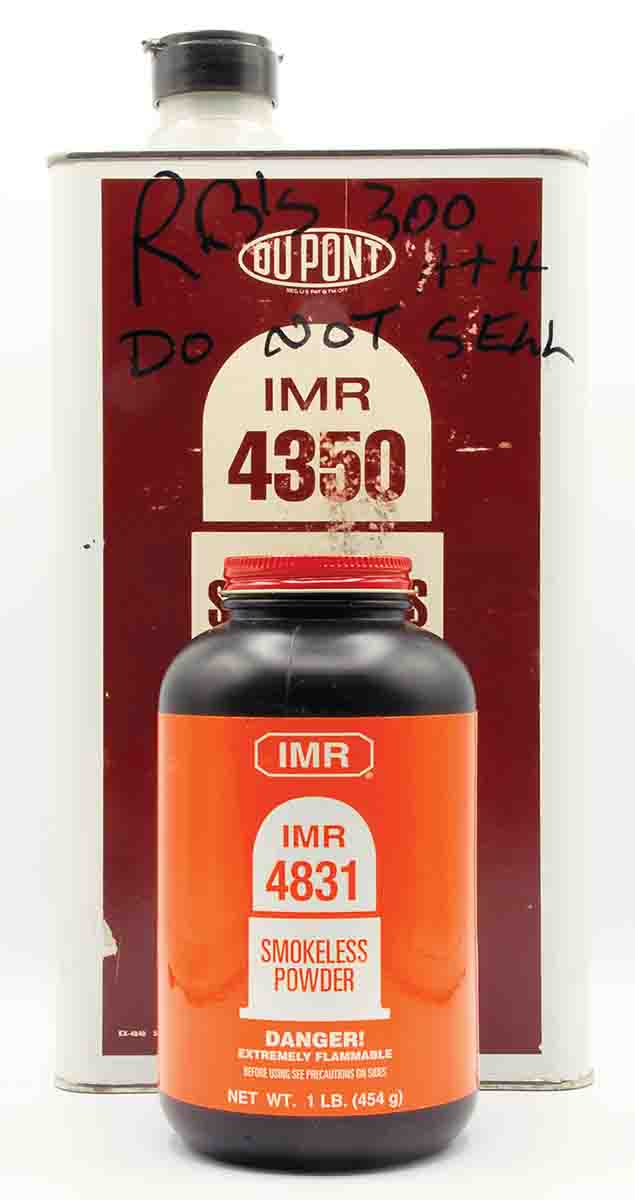

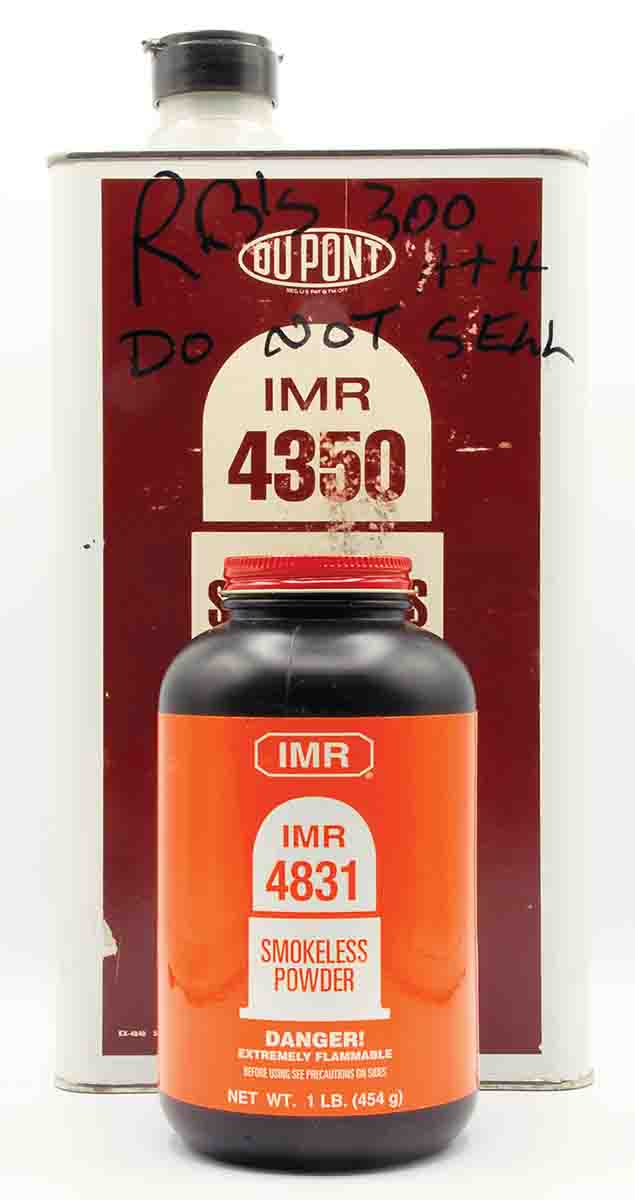

Randy’s approach to handloading is, “if it works, it is not broken and does not need fixing.” IMR-4350 and IMR-4831 work as well today as ever.

The Highlander is a delight to load for, to the point where although I have tested many different loads as bullet designs and propellants have changed, I have two loads that have become my all-time standbys. The load I use the most is the Nosler 200-grain Partition loaded over 64 grains of IMR-4831. Remington 9½M primers initiate the powder burn. This load consistently prints very nice groups ranging from .635 to .720 inch at 100 yards. Recently, the Highlander shot a very respectable five-shot group measuring 1.671 inches at 200 yards.

For antelope, whitetail and mule deer, it just so happens that a load which has been a long time favorite of Brutus, my pre-’64 Model 70, comprised of either a Sierra GameKing 165-grain softpoint boat-tail or Nosler 165-grain Partition bullet loaded over 68 grains of IMR-4350 with a Remington 9½M primer, shoots exceptionally in the Sako Highlander as well.

While a lot of capable new powders have come on the market over the course of the last few years, I am still a big fan of IMR-4350 and IMR-4831 powder in the .300 H&H Magnum. I am a proponent of the “keep it simple” principal and if is not broken don’t fix it. IMR-4350 and 4831 worked great years ago and it works just as well today, so I personally see no need to change.

So that is how a rifle and cartridge combination that, by the book, never existed, truly does.

.jpg)