Mike's Shootin' Shack

Colt SAA .38-40/.38 WCF

column By: Mike Venturino | August, 17

One of my all-time favorite cartridges is the .38 WCF, aka .38-40. I’m not completely sure why, as it can be a fragile round to handload. Case walls are thin, easily crumpled, dented or creased when resizing and during bullet seating. Being of bottleneck construction, special carbide-type dies are not available, so lubing for sizing is a necessity. Also, some brands of reloading dies will not set case shoulders back enough to freely fit in tight revolver chambers. (I’ve never experienced this last problem with any .38 WCF rifle or carbine and have owned dozens – Winchester, Marlin, Uberti and Colt.)

All my .38 WCF revolvers have been Colt SAAs except for one, a Colt New Service. At this writing, I own five SAAs so chambered. Three are 3rd Generation production and two are 1st Generation: one a standard SAA and the other a Bisley. No Colt SAA .38 WCF/.38-40 revolvers were made during 2nd Generation manufacture (1955-1974).

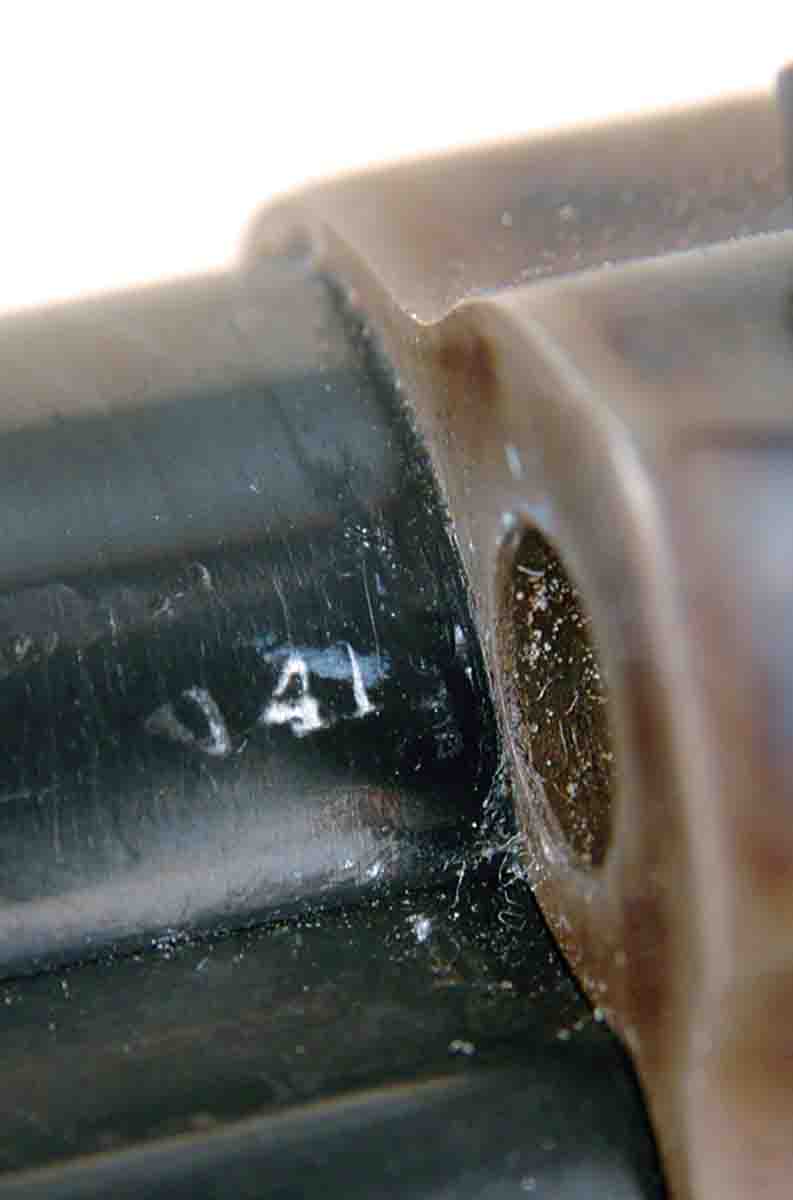

A great many 1st Generation Colt SAAs have a tiny “41” beneath the barrel under the cylinder’s base pin. The two currently on hand do not. They were made in 1902 (Bisley) and 1904 (SAA). Also worth mentioning are .38 WCF/.38-40-caliber designations. During 1st Generation production, they were stamped “.38 W.C.F.” Starting in 1993 with the return of the cartridge in 3rd Generation production, they were marked “.38-40.” Then in the late 1990s, some were given the old .38 W.C.F. stamp again. I own two.

First Generation (1884-1941) standard Colt .38 WCF barrel lengths were 43⁄4, 51⁄2 and 71⁄2 inches, but others could be purchased on special order. The chambering was the third most popular when 1st Generation tallies were made. Upon reintroducing the caliber in 1993, Colt initially only offered 43⁄4- and 51⁄2-inch lengths. At the 1996 SHOT Show, I approached the Colt Custom Shop boss about getting one with a 71⁄2-inch barrel. He said, “Well, I am making some like that for Hank Williams Jr., but I won’t do it for you.” I left the Colt booth, went to the nearest FAX machine and sent Hank a message asking if I could buy one of his when they arrived. He replied, “Most certainly, my friend.” The next day I showed Hank’s response to the Colt guy who said, “Why didn’t you tell me you were friends with him?” I replied, “I shouldn’t have had to.” To my great pleasure, when a 71⁄2-inch Colt SAA arrived from Hank, it was stamped “.38 W.C.F.” instead of .38-40. Colt made more revolvers with 71⁄2-inch barrels in the late 1990s, and along the way some were made with special 33⁄4-inch barrels. I had one of those for a while.

Another variation in 1st Generation SAA .38 WCFs was the Bisley version. It was the second most popular chambering in that

Barrel groove diameters and cylinder chamber mouths of 1st Generation Colt SAA .38 WCFs can vary enormously. One friend’s 1914 vintage example measured .408 inch across its barrel’s grooves and .401/.402 inch in its chamber mouths. Of the two here currently, the standard SAA version has six uniform .400-inch chamber mouths. The Bisley has four at .400 inch and two at .399 inch. Their barrels slug a whopping .405/.406 inch and a more reasonable .402/.403 inch, in the same order. Shooting will determine how well or how poorly they perform. I hold little hope for the first. Conversely, all the 3rd Generation examples I’ve measured have had .400-inch barrel groove diameters and .400- to .401-inch chamber mouths. Small groups with 1st Generation Colts of this caliber may be achieved. With 3rd Generation revolvers, small groups are almost certain. With winter’s weather improving every day, I’ll soon know for sure.