Practical Handloading

Sectional Density and Performance

column By: Rick Jamison | October, 19

Bullet company handloading manuals list a couple of numbers with each bullet. One is ballistic coefficient (BC), a numerical indication of a bullet’s ability to overcome the resistance of air in flight. The other is sectional density (SD). Sectional density is defined as a bullet’s weight in pounds divided by the square of its diameter in inches. High sectional density is said to be essential to producing a good BC and deep penetration.

As for penetration, the practical significance of SD has changed somewhat over the years. Back in the day, when rifle bullets were nearly all constructed by inserting a soft lead core into a cup jacket without bonding and without much jacket-wall variation, SD was important. In those days a hunter needed bullet length to ensure adequate penetration. The reason was that bullets lost a lot of weight during impact and penetration. On impact, bullet jacket petals flared open wide to expose the soft-lead core, then as the petals peeled back, core weight was smeared off and lost. If a jacket peeled back enough, the core was lost completely. A bullet with little weight penetrates little.

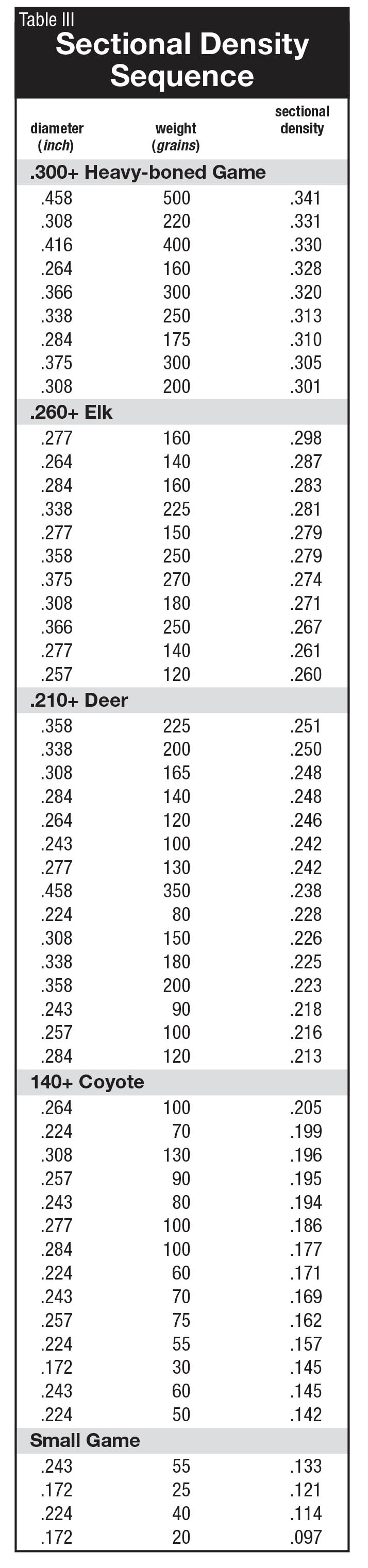

There are even minimum sectional density recommendations for various types of game; for example, a minimum .210 SD might be considered for deer, .260 for elk and .300 for heavy-boned game. I still prefer a minimum .140 SD for coyotes because

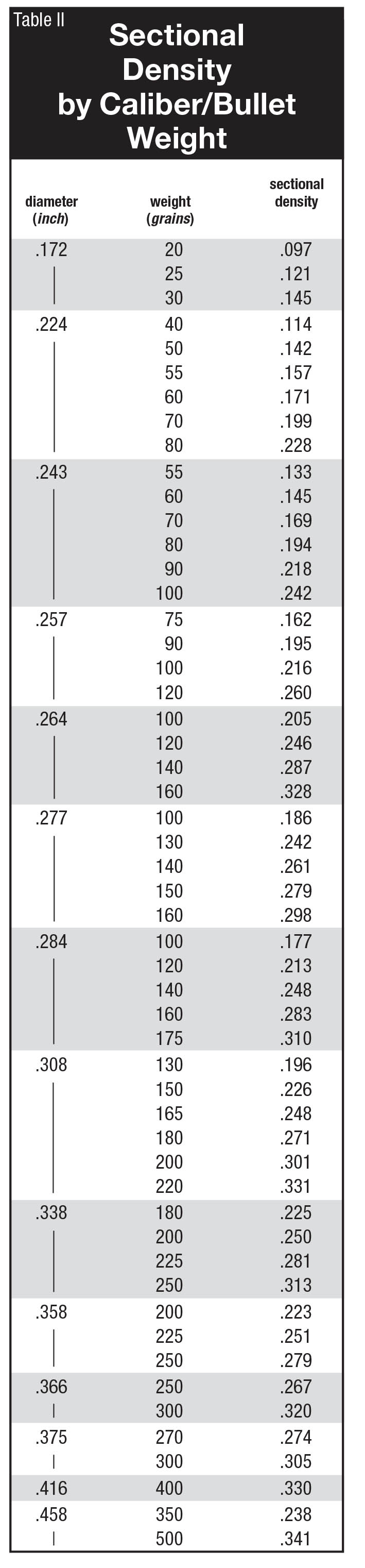

For the average hunter, sectional density is usually referred to in terms of bullet weight for a preferred caliber. For example, a 150-grain bullet is considered to be a deer bullet in a 30-06. For elk, a 180- or 200-grain bullet is the recommendation in .30 caliber. I have included a couple of sectional density tables to show how SD relates to caliber and

Today, however, things are vastly different. We have bullets of a wide construction variety. We have bonded bullets, bullets with cross members, bullets with thick and tapered jackets. There are bullets with harder lead cores, bullets with lead only in the base, and others with lead only in the front portion. There are also bullets of homogeneous and heat treated metal, and bullets with steel inserts.

For the most part, these bullets are designed to prevent excessive expansion and retain weight on impact. Some of today’s bullets retain nearly 100 percent of their original weight. The result is that lighter bullets penetrate much better now than in years past. Remember, SD (weight) does not encompass bullet construction.

For these reasons a bullet lighter in weight with special construction can sometimes out-penetrate a cup-and-core bullet. For example, a 130-grain .277-inch bullet has an SD of .242; significantly lower than the minimum .260 SD recommended for elk. Even so, I have used thickly jacketed and bonded Swift 130-grain Scirocco IIs from a .270 WSM to take a fair number of very big elk and have not lacked for penetration. One was taken at a short 80 yard – where impact velocity was high, probably 3,100 fps. The bullet retained a lot of weight and there was certainly no lack of penetration. This same load expanded and penetrated a deer lengthwise on the far side of 600 yards.

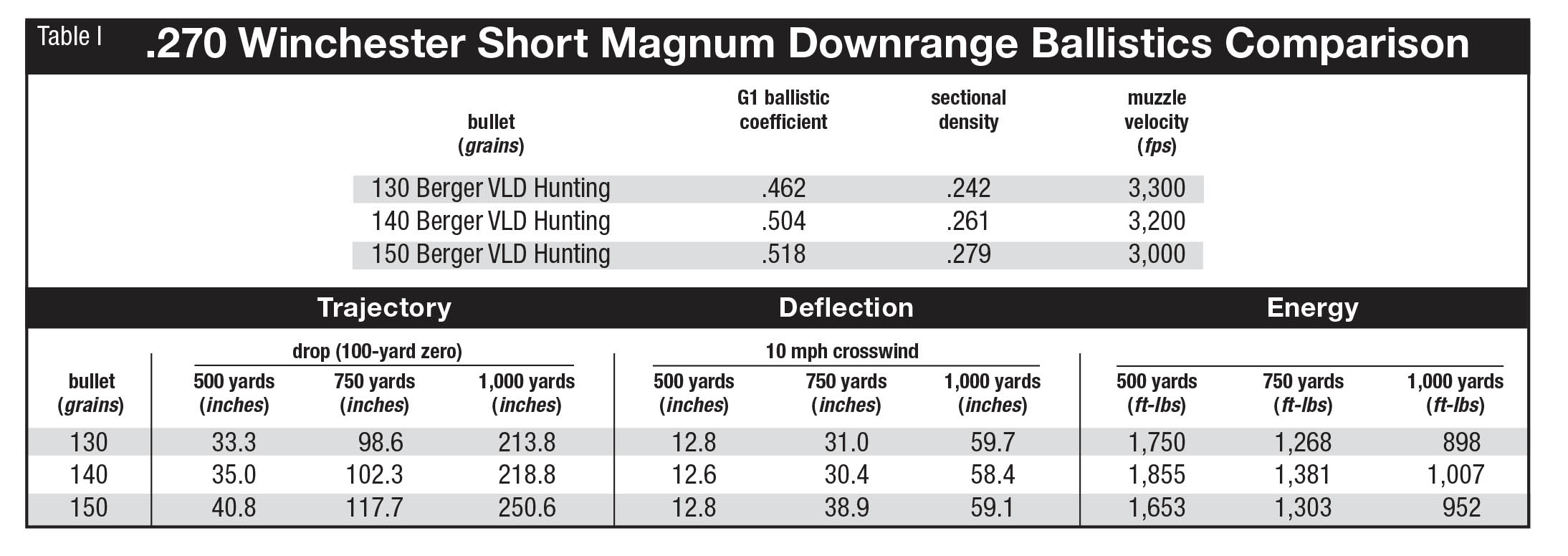

Some handloaders talk about heavy (high SD) bullets being less deflected by wind. However, if the numbers are run, taking into account the reduced muzzle velocity for heavier bullets, there is almost no wind deflection, energy or drop advantage to a heavier bullet in a specific caliber.

An accompanying table derived with a ballistic application using all same-shape Berger VLD hunting bullets reveals that with .270 WSM velocities, the mid-weight 140-grain bullet comes up best overall. It is best in the wind deflection and energy categories while the lighter 130-grain bullet is best in the drop category out to 1,000 yards. The heavy and high SD 150-grain bullet with the highest BC is not best in any category.

Muzzle velocities and BCs can vary, but in a given cartridge a heavy bullet is a tradeoff with lower muzzle velocity. This negates any real in-flight advantage for a heavy bullet. This leaves only penetration for the heavy bullet advantage, and that advantage comes only by ignoring bullet construction. Today, the latter is really the significant factor in penetration. As can be seen, the significance of SD is not the same today as it was years ago.

This fact comes into play particularly for a handloader, for example, with cartridges that push the performance envelope with an action of a given length. The .284 Winchester, .300 Winchester Magnum and all the short magnum-type rounds come to mind. Some handloaders do not like the idea of seating bullets much below the base of a case neck for whatever reason. With the bullets mentioned above that are designed for weight retention and controlled expansion, such a long and heavy high-SD bullet is not necessary. A 150- or 165-grain bullet might be more than adequate in .30 caliber where before a 180- or 200-grain bullet was deemed necessary. In 7mm, a 140 might do the trick where a 160 was used before. This means that less of a bullet’s base protrudes into the powder space with a given overall cartridge length.

None of this applies to nonexpanding bullets for African game, nor are we talking about hard-cast nonexpanding bullets used in handguns. We are talking only of popular expanding rifle bullets used in game cartridges today.